When it comes to Australian solar installations, conventional string inverters tower over the competition like a current converting colossus. But microinverters, which are tiny in both physical size and market share, are shaping up to beat string inverters on both price and reliability. Enphase, the world’s largest producer of microinverters, plans to beat conventional inverters on price within two years. If they meet their goal of cutting micro inverter costs in half, it will change the way Australians install solar power.

When it comes to Australian solar installations, conventional string inverters tower over the competition like a current converting colossus. But microinverters, which are tiny in both physical size and market share, are shaping up to beat string inverters on both price and reliability. Enphase, the world’s largest producer of microinverters, plans to beat conventional inverters on price within two years. If they meet their goal of cutting micro inverter costs in half, it will change the way Australians install solar power.

What The Hell Is A String Inverter?

This is a string inverter. image: SMA

You can find the details of differences between string inverters and microinverters here or you can check out this infographic. But in a nutshell, string inverters are far more common in Australia and 99% of our solar installations use them. They are big here. And I don’t just mean popular, they are physically large. Typically a 5 kilowatt one will take up as much space as 35 liters of ice-cream, or the same quantity of less delicious material, and weigh about 24 kilograms.

String inverters use solar panels connected in series on a line called a string that sends Direct Current (DC) to a central inverter which it converts it to the Alternating Current (AC) we use in our homes. While this inverter will try to maximise the power output of the panels, the drawback is if one panel on a string performs poorly all the panels will perform poorly. Because of this it is very important all the panels on a string share the same orientation and receive the same amount of sunlight.

The main advantage of string inverters at the moment is price, as so far they have been cheaper than the microinverter competition.

For example: a 5kW string inverter will wholesale from $1,000-$2,000 depending on the quality. Whereas 5kW of micro inverters will be closer to $3,500.

What The Hell Is A Microinverter?

A microinverter. image: Enphase

In a nutshell, microinverters are little baby inverters that attach beneath solar panels and directly convert a panel’s DC into the AC used in homes and does away with the need for a central, string inverter. While cables that carry DC are extremely safe when installed to Australian standards, AC is even safer because if something does go wrong it is much less likely to start a fire.

Microinverters optimise the output of each panel they attach to, so if one panel has a problem it won’t affect the performance of the others. This means they will generally produce 5-15% more electricity overall than string inverters. If the two types are matched on price per watt microinverters will be cheaper overall, as fewer panels are required to generate the same amount of electricity. And because the panels are independent from each other they can be arranged as desired to maximise a household’s self-consumption of solar electricity.

Microinverters are very small. They don’t yet fit in a nutshell, but I was brought up in Queensland where the large nuts come from, so I can tell you they are getting close. Today’s microinverters can easily fit in my outstretched hand. And for people who are less mighty than I am… well, they probably would fit in your outstretched hand too.

The main disadvantage of microinverters at the moment is price. As a result of the extra cost they are only used in about 1% or less of Australian solar installations. But there are companies looking to change this.

What The Hell Is Enphase?

Enphase is by far the world’s largest producer of microinverters. But there are other companies also in the business, and there are plenty more waiting in the wings ready to enter the field and play catch up as soon as one of the others demonstrates the ability to compete with string inverters on price.

What is likely to result is a titanic battle for market share. Enphase has the advantage of size, experience, and reputation; but small companies can be nimble and large ones have deep pockets and will be willing to burn money in the short term to catch up if they think large profits can be reaped in the future. Regardless of who is left standing, the resulting price cuts ensure conventional string inverters will be a major casualty.

Personally, I hope no company wins. I want them to keep slugging away at each other to the benefit of consumers with improved reliability in one fist and lower prices in the other. That’s my version of utopia. A boot stamping on the face of microinverter prices and reliability issues forever.

A DC Optimiser.

But that lies in the future. Right now Enphase’s biggest competition isn’t from other microinverters but DC optimisers. This technology is superficially similar to microinverters in they go under individual solar panels and maximise their output. But they are cheaper and don’t convert the solar panel’s DC to AC. Instead they still require a conventional string inverter to do so. Obviously, if households can get the main benefit of microinverters for around the same or lower cost, that is a major problem for Enphase.

The largest producer of optimisers is Solaredge and they definitely have the potential to lower the cost of their product using the same sort of cost cutting measures Enphase plans to use for its microinverters. But because optimisers are reliant on string inverters they are much more limited in how low their costs can go. So they may have an edge now, but in the long run microinverters seem certain to win on overall system cost.

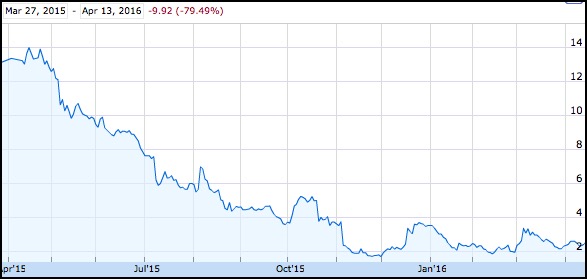

Unfortunately, as far as investors are concerned, Enphase hasn’t been doing too well lately. Their share price has fallen 86% from its peak one and a half years ago:

Enphase Stock (ENPH) has dropped 86% in 18 months.

While Solaredge’s has only plummeted 41%.

Solar edge (SEDG) stock has dropped 41% from its peak.

But a choice between innovation or death can spur companies to perform great feats. When the stakes are high and the chips are delicious, taking a risk on investing in new technology could be exactly what Enphase should do. They just have to hope Solaredge doesn’t gain an edge first, otherwise they would become Solaredge Squared. And that would be a frightening thing to have to compete against.

Don’t pay too much attention to Enphase’s low share price. After all, if investors are so smart, how come the rest of us have any money left at all? But on the other hand, investors do put their money where their mouths are, so they could be onto something. There are legitimate concerns about warranty obligations. After all, just how valuable is a 25 year warranty if it is not clear the company will be around for that long? That said, Enphase is currently a large company that produces high quality products and has the capacity to manufacture and ship a great many teeny tiny inverters.

How Reliable Are Enphase Microinverters?

In 2008 Enphase released their first generation microinverter and not too long after that the second generation. Unfortunately, it appeared they were cursed unto the second generation and they both experienced higher than predicted rates of failure. This hurt the company’s bottom line and damaged its reputation. Then in 2011 they introduced their third generation technology and its rate of failure was lower than expected.

So the lesson is, if at first you don’t succeed, try, try again. Provided you are actually getting better at what you are doing. There are some companies out there that really should have stopped trying a long time ago. And another lesson to take from this is, doing stuff is hard and doing stuff that is new is really hard.

The first and second generation microinverters came with 15 year warranties. And that ended up biting them on the bottom. But their third and later generation models came with 25 year warranties in the United States, which is the longest warranty I am aware of for any inverter of any type. And they have performed very reliably to date. Unfortunately, it is still too early to be certain they’ll last the full distance.

But things get interesting when it comes to the warranty we get down under. In the UK, which has identical electrical current to Australia, they have a 20 year warranty. But in Australia Enphase currently only offers a 10 year warranty. Now conditions do vary between here and America. For one thing it gets hotter on average in Australia, although I do hear it also gets hot in states such as Nevada, particularly around some place called Death Valley.

Apparently the warranty is shorter in Australia for, what are to me, inexplicable legal reasons. So while we miss out on the 25 year warranty, the fact their warranty is that long in the US is a good indicator of reliability.

Enphase’s Price Target

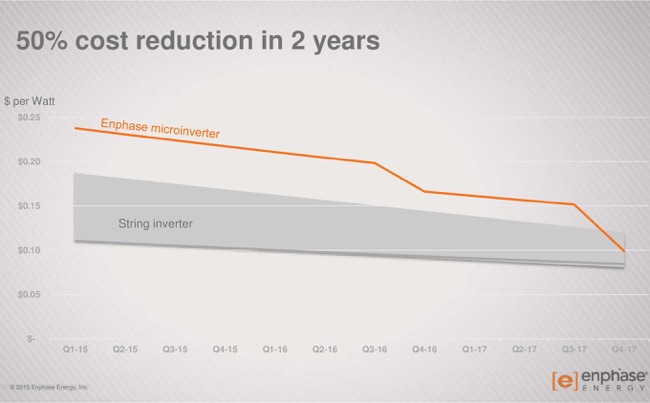

Enphase aims to get their price down to about 13 cents a watt by the end of 2017. This is the same as premium (SMA/Fronius) string inverters are expected to cost at that point and, because microinverters produce more energy per solar panel, this means they will effectively be cheaper.

This hard-to-see graph from Enphase shows what they hope to achieve. Their target of 10 US cents a watt comes to 13.1 Australian cents at today’s exchange rate.

Enphase’s cost reduction plan. image: Enphase

How Enphase Will Cut Costs

To cut costs Enphase has a multi-pronged plan. And provided each one of these prongs is successfully achieved, it appears likely they will meet their goal of beating string inverters on price before the end of 2017.

And I have to admit that, as I studied their prongs, I grew increasingly excited. So while other tech fanboys have recently been drooling over the Tesla 3 electric car, I have been drooling over the specifications of planned future Enphase microinverters. After all, why would I need an electric car when I have a perfectly serviceable and good looking horse?

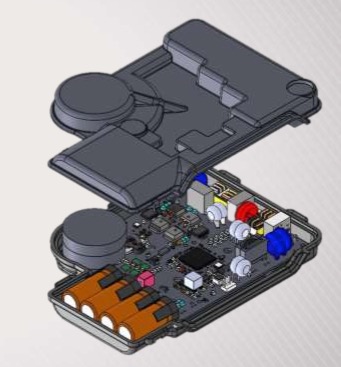

- One prong is to is to replace the microinverter metal exterior with a stylish tough plastic case that is sure to impress the sorts of guests who go around peeking under your solar panels.

A plastic enclosure is less than half the cost of an aluminium one. Image: Enphase

- They also intend to improve the efficiency and function of components. They also will reduce the total component number, and I am certain this will be done in a sensible way and not at all at random.

- Wiring will be made simpler (from 4 down to 2 AC wires)

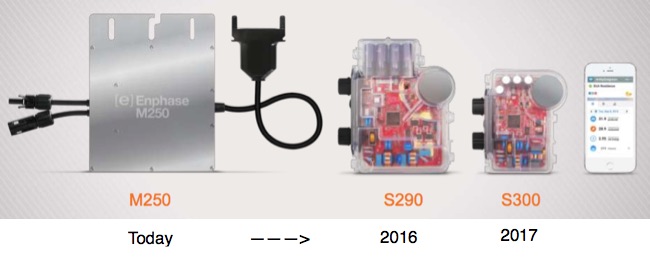

Their planned 2017 model will be so small its length and breadth will be roughly the same as that of a smartphone:

Enphase Microinverters’ projected size reduction. Image: Enphase

However, it will be a heck of a lot thicker. Especially compared to the latest smartphones which are so thin I could just about shave with them.

Panel Integrated Microinverters

Another way Enphase is looking to reduce costs is to integrate microinverters with solar panels. This means panels can be purchased with inverters already attached which will simplify installation and reduce its cost. In fact, Tindo Solar is producing panels with integrated Enphase microinverters in Adelaide right at this moment. If you are interested, get in touch and tell them I sent you. Or don’t tell them. I don’t really mind either way.

I Think The Future Looks Bright For Microinverters

I am cautiously optimistic about Enphase’s plans to cut microinverter costs. Sure, they face the risk that errors in their estimates of failure rates for their 25 year warrantied microinverters could wipe the company out. And there are more general concerns they may not make enough money to be able to stick around long term.

But if Enphase doesn’t manage to cut microinverter costs, someone else will. And Enphase is definitely in with a chance. They’re still a player. And if they can’t make it, the question is not ‘will someone reduce the cost of microinverters’, but rather, ‘who and how long will it take?’ And if I knew the answer to that, I would tell you. Right after I bought up all the stock real cheap.

I am confident microinverters will come down in price and eventually outcompete string inverters. This type of small scale integration of electronics into devices does appear to be the direction our technology is heading in.

Microinverters beating the old guard on price might not happen within two years. But maybe it will. I say good luck to Enphase. And I also say good luck to their competitors. And in the hope they will continue to compete against each other to our benefit, I say may the best teams stalemate.

[Disclosure: Finn’s super fund owns Enphase stock]

RSS - Posts

RSS - Posts

Good on you Finn, one the better bloggers on renewables around. We talk so some much about future products … we forget the nuts and bolt of solar. Even 0.5% improvement in efficiency with modern micros over 15 years adds up.

HI Lindsay,

Thanks for the kind words – although credit should go to my colleague Ronald – who actually wrote it!

Cheers,

Finn

Thanks Lindsay, I appreciate you letting me know you liked the article.

That’s food for thought. For off-grid, a simple 240 Vac battery charger would do, with microinverters, instead of an MPPT battery controller, like the TriStar. But, hey, I’d still need the battery inverter as well, at night. (As will anyone adding batteries for load-shifting while still grid-connected.) The DC-AC-DC battery charging path dictated by microinverters has to be less efficient. Even 0.94^2 is down to 88%. To use the battery power, we’re going DC-AC-DC-AC, for maybe 83% conversion efficiency. Even if battery efficiency is 90%, we’re down to 75% total.

The DC optimisers sound interesting, if they do what one might assume. A bypass diode on each panel should stop a narrow chimney flue shadow ruining the output of a whole string, if I’ve caught on correctly. But we are then down one Vmp on that string, and need an MPPT per string for the other(s) to give their best, I figure.

Is it the case that a DC optimiser is a per-panel micro-converter (MPPT), improving on a simply bypass diode by drawing what it can from the shadowed panel to provide some positive voltage, rather than the loss of the diode drop? Heck, what’s the payback on those few watts? The units would have to be cheap, as you need one per panel subject to shading.

My strawbale design has a flue shadow walking along one string for a few winter months. Being unable to find a way to move the flue, I’ve thought as far as adding bypass diodes. I’ll have to look into the optimisers.

Hi Erik,

Tigo’s new TS4-O optimisers can be retrofitted on individual panels in a string and optimise only those panels.

The key thing is that- now – you don’t have to have an optimiser on every panel in the string (assuming 1 string per MPPT).

So you can spend $50 per optimiser and bolt it onto only the panels that are affected by the flue shadow, and you’ll get lots more energy from the whole string.

The TS4 dc optimiser platform is really interesting – especially for applications like yours – I’ll add it to the list of upcoming blog posts.

More details here:

http://www.tigoenergy.com/ts4/

Hope That Helps,

Finn

Many thanks, Finn, for the link. The TS4-O text didn’t elaborate much, so I’ll certainly be paying attention when the blog post pops up.

On the long narrow E-W north-facing roof, I can readily fit two 12-panel strings, one above the other. That 6 kW should yield 1.5 kW on a grey day, enough to avoid drawing battery power close to 100% of the time, I think, as the washing machine wouldn’t be run, and most other loads are similarly discretionary.

The flue shadow, from the north-extending wing of the L-shaped building, won’t touch the top string, but sweep over all 12 lower panels each day in winter, when the sun is lowest. (38 -24 = 14 degrees above horizon, I figure, and the angle from base of bottom string to flue top will be 18 deg.)

Twelve $50 optimisers is $600, to get a few extra watts out of just one panel in the string. (That’s all that is shadowed, so 11 will always be doing exactly nothing.) The $/w seems plain wrong, as cheap bypass diodes will just zero out the one shadowed panel without fuss or high cost. It is just possible to squeeze a 13th panel into the lower string, making up the winter loss for less than $600. If Schottky diodes are used, the voltage drop is low.

Looking at the 85 page manual for the Tristar-mppt-600v battery controller, I see that one could parallel two of them, both to get two MPPTs, and to handle the power. Towards the last page it did reveal that the “600v” unit shuts down completely by 525v, and only produces maximum power between about 200v and 400v. In addition, the efficiency, much touted in the short-form blurb, is not graphed towards top rated output power. I’ll ask them whether that’s because it’s so good that they’re embarrassed. (Unless I find something more attractive out there.)

I liked the article Finn but please stay out of politics. No need to make a jab at investors when Enphase does carry a fair share of debt and low profitability.

Also it would have been good to hear about battery setups with regards to microinverters, DC optimisers have an ‘edge’ there too at the moment.

Matt, actually it was my article. And I’ve been known to invest from time to time, so really I was making a jab at myself.

Hi Matt/Finn. As an Electronics Engineer, I worry about putting electronics, particularly the high-voltage stressed switching devices in a 40VDC-240VAC inverter, on an Aussie roof in the high summer.

The good old bathtub curve of semiconductor junction reliability shortens markedly for every few degrees above 70C. Sticking a MOSFET or IGBT switching device, that probably runs at junction temps about 40 C above ambient into an ambient of at least 60-70 C (in a plastic case over a zincalume roof under a dark blue panel that’s re-radiating in the infrared) seems a recipe for premature failure. Add to that the thermal/power cycling every day…

I’d give it 5-10 years, so I’m amazed that Enphase can offer a 25 year warranty in any ‘hot’ country. Guess smarter people than me have crunched the numbers. I like the thinking but will wait a few years before I believe it.

Question – are microinverters isolating or do they float the panels on the 240VAC line by series switching to inject the (modulated) DC current? That would put some pretty interesting voltages up there on the roof! You’d want to make sure it’s well grounded (for steel).

Hi Andrew,

Keera from Enphase has replied below:

Finn

Hi Andrew

I’m a PV engineer working for Enphase and when I first joined Enphase I was pleasantly surprised to find that our micros generally run much cooler than you might expect. Yes it’s warm up on the roof behind the module, but as each micro is only switching approximately 30V DC and 250W, they normally have a thermal footprint of 5 to 15 degrees C above ambient. Given that each micro is fully potted, heat dissipation is very good, and we have a much lower internal temperature that what I’ve seen in string inverters that are often switching 3000 to 5000W at up to 600V DC.

I can often see the internal temperatures on my parents’ string inverters installed in a garage sitting between 80 and 95 degrees C, and at the same time when I speak with some of our Sydney-based Enphase installers, their systems are reporting micro temperatures under 60 degrees C. We also did a more detailed study into temperatures experienced across Australia with more info via http://info.enphase.com/rs/enphaseenergy/images/Enphase_Heat_Myth_Topic%20Brief_AU_Final.pdf

We’ve done a LOT of R&D into the lifetimes of the semiconductors and components we use in our micros, and recently expanded our Christchurch facility to be able to do a lot more Accelerated Lifecycle Test, where we put our micros (whilst powered up) through many of the same tests carried out on solar modules. We have more info on that testing on the Quality & Reliability page on our website via https://enphase.com/en-au/company/energy-evolved#quality

In Australia and New Zealand, Enphase opted for a 10 year parts and labour warranty, not 25 years parts and 2 years labour like in the US market, but we do have similarly high temperatures and humidity in different parts of the country.

Our micros are HF transformer based, not floating, and all PV installation standards have required frames and mountings to be earthed for a number of years now, so we don’t see and induced current building up on the roof.

Cheers

Keera

Kerra, thanks for your background explanation on this topic. As an installer my main consideration is safety, no high voltage DC isolators on the roof i.e. NO FIRES

With an Ausnet restriction of 4.6kW based on panel specs, I have recently installed 16 Jinko JKM270PP-60 panels with Enphase S230 micro inverters. I asked the salesman if this combination was correct and he referred to others for advice and came back saying the inverters can be run ‘over loaded’ to up to 30% and survive without affecting warranty. I believe I understand a little more now that the inverters are happy with that input but will not output more than their rating. I thought I had bought a 4.3kW system but now I believe I have a 3.68kW system due to the inverters max output. Should we have gone with the S270 inverters instead? I asked the company again this week. Their reply, It would not be viable as the s270 is $250 each more than the S230.

I would appreciate your comments.

Hello Trevor. Solar panels are permitted to be up to one-third greater in capacity than the inverter while still receiving the STCs that lower the cost of rooftop solar in Australia. Within that limit, having more panel capacity than inverter capacity has almost no effect on the total output of the panels. I wrote about it here:

https://www.solarquotes.com.au/blog/oversizing-solar-arrays/

Your system has 17% more panel capacity than inverter capacity and so the output will be almost identical to what you would have if you had spent more to get the 270 watt microinverters.

The system sounds fine to me and Enphase microinverters are very reliable, so hopefully it will operate without problems for literally decades.

Thanks Ronald.

I read your link go to wow , thanks. In it you mention systems being limited by power companies by limiting the inverter capacity. I thought that would be the correct way but was told by my supplier that Austnet’s restriction is on panel capacity. Therefore my allowed max of 4.6kW has resulted in (16panels @ 270w=4.32kW into 230w output inverters) a system max output of 3.68kW. Nowhere near Ausnet’s 4.6 limit. I could/would’ve installed more if the limit was on inverter capacity.

A bit more to my solar story after watching my system operate since Jan 17. The best day that i have seen had a peak production of 3.5kW. I think it has done well considering it consists of 6 east and 10 west facing panels on either side of a 22 degrees pitched north aligned tin roof in Nagambie Vic.

My system includes the Envoy S with monitoring which I believe can also control the Micro Inverters to limit feed in. You may be able to confirm this for me.

On recent investigation I have been told by my original installer that Ausnet have changed their rules regarding how max feed in can be controlled. By adding another 6 panels and S230 Micro Inverters I could bring the system up closer to 5kW on that same day and preventing too much feed in with the Enphase software.

What do you think?

Australian warranty law dictates that the seller (enphase in this case) when honoring a warranty is liable for shipping costs…probably a cost that would be similar to repair/replacement for something like an inverter. In America, if it breaks, the consumer in most cases, is responsible to get the item back to the factory or other authorized service center. There may be other legal “costs” that are not obvious also.

As a side note, I have a mate that had a new caravan that had several items that needed warranty attention. The company asked him to take the unit to Melbourne and his response was, “Here is my address, honor your warranty.” …the company came and picked it up and carted it to their factory, and when the repairs are done, they will cart it back. That is no small cost and extraordinary customer service….it is no wonder costs here are more for comparable items and warranties are a bit tighter. Also, if companies don’t honor a warranty, the Australian government will go after the company, but in America, you would likely have to hire an army of lawyers to get your warranty honored.