Mechanical battery storage solutions provider Key Energy recently installed a flywheel energy storage system for a school in New South Wales.

The Armidale School, located as the name suggests in Armidale, was founded in 1894. It’s a co-ed boarding school with a current enrolment of more than 640 students, including over 200 boarders.

Among its many facilities is a creative arts precinct incorporating a 240-seat performance theatre, a music centre, a heated indoor 25 metre swimming pool, gymnasium, seven sporting ovals (one under lights), rifle range, basketball courts and seven tennis courts.

In other words, the school’s energy bills would be eye-watering.

The school has already headed down the renewable energy path through installing solar power and a battery system. Its latest project involves a different type of storage – flywheels.

What Is A Flywheel Energy Storage System?

The flywheel used in this application is essentially a mechanical battery consisting of a mass rotating around an axis in a vacuum, levitated by a magnet and riding on special bearings that minimises frictional losses. The mass is rotated to very high speeds (9,000 RPM) using an electric motor.

Once the system has reached the desired RPM, it takes very little energy to keep it at that speed. When energy needs to be extracted, the motor becomes a generator. Basically, electrical energy is converted to kinetic energy and converted back to electrical energy when required.

Some of the advantages of flywheel energy storage systems is they are low maintenance, there’s no fire risk, they have a claimed service life of 20 – 30 years and can be easily recycled.

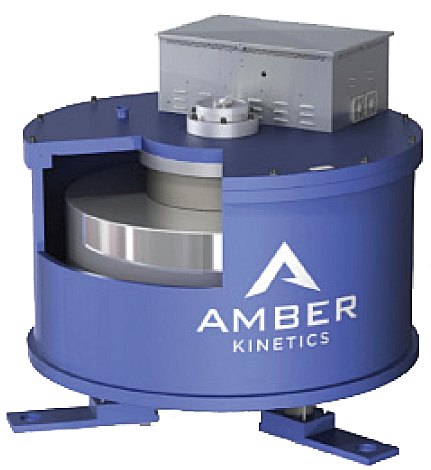

Key Energy has installed four flywheel systems at The Armidale School that have been buried underground. Each unit offers 32 kilowatt-hours capacity for a total of 128kWh. The devices used were manufactured by California-based Amber Kinetics, which describes its Kinetic Energy Storage Solution (KESS) as being:

“..the first commercialized four-hour discharge, long-duration KESS solution powered by advanced technology that stores 32 kWh of energy in a two-ton steel rotor.”

.. so, 8kW of power per unit. That two-ton mention is just the rotor – the entire assembly weighs 10,500 lbs, or around 4.76 tonnes. That’s incredibly heavy for what appears to be a very compact setup. Amber Kinetics claims an >86% round trip efficiency (DC), and a life of 11,000 cycles for its KESS.

More solar panels were installed as part of the project in addition to the KESS, bringing the school’s total solar capacity to 145kW.

There’s nothing mentioned on its website, but according to The Armidale Express, the school also has a large conventional battery system in place – a lithium-cobalt-manganese unit (brand not mentioned) with around 270 kilowatt-hours of storage.

The school says the project is not just about generating more energy, but storing it more efficiently and then distributing it more evenly. Flywheel storage was chosen based on five years of usage data.

“As a large boarding school with energy needs that vary around the clock, the system’s prime function is to remove the regular spikes in our grid electricity consumption which cost us very expensive network capacity penalties each month,” said the school.

As for what the flywheel systems + additional solar power capacity cost isn’t mentioned, but the project is expected to pay for itself with savings within five years.

RSS - Posts

RSS - Posts

The Batteries do not look to big, it would be quite a usable size to have at a home.

But they must be exceedingly expensive or i am sure we would have heard of them before.

While it is a great concept, the school is far away from being one of the first to use this technology, although one of the first that spin on a vertical axis rotor. There are many flywheel based backup systems in use that even I know of but most use a horizontal axis rotor. Most of these sites claim to be maintenance free but usually have an annual shutdown to check the machine as it gets annoying if it spins for several years then fails when loaded up.

I have often wondered what was wrong with flywheel energy storage. I assumed that there must have been significant energy loss but it seems not to be the case. Can you ask why the life is limited to 11000cycles?

The speed sounds low to me. Why wouldn’t you use a very high speed such as used reliably in engine turbo chargers 70 to 100 thousand rpm. Energy goes up as the square of the speed. Is the speed limited by the strength of the flywheel material?

Turbo-charger size (diameter) is MUCH smaller than this flywheel. 70k-100k RPM would just cause the bigger diameter flywheel to explode. From memory (more than 50 years ago that I studied physics/applied mathematics !) I think that the radial forces go up with the square of the radius (?), and the radius of this flywheel would be about 10 times that of a turbo charger impeller/armature. And that would make the forces acting about 100x greater than those on the turbo-charger — and that would cause the flywheel to rip itself to pieces. Do note, that these flywheels are buried below ground so that if they DO explode, that the debris would be contained by the earth.

PS: that’s the same reason that a human flies off a kids’ playground merry-go-round at about 30 rpm 🙂

When will the flywheel battery system be available for sale

Thank you

I’m afraid if you are interested in one for household use they’re not suitable for that kind of application. What they are good at is providing a lot of power for a brief period of time.

I recall reading recently, in New Scientist I think, about a US company that had developed a much smaller mechanical flywheel battery based on 20cm discs pancaked together into modules. A household sized prototype was already operating on the developer’s home with his rooftop solar system

Sorry Ronald, that’s not correct at all.

In fact I’m involved with a company that is currently installing these identical (although a different brand) flywheel generators in domestic situations at the moment.

These are test case in selected areas.

They are coupled with solar panels and storage batteries and are fine for domestic applications.

I hope you can give the home battery market some competition. If your test cases go well please let me know, as that’s the sort of thing I’d like to write about. If they don’t turn out well I’d still like to write about them, but I can understand if you’d rather not talk about it.

Hi Sean, any more details on the flywheels you were installing? We are a year down the track are you able to share what you found with the trial sites? Thanks

Sounds fascinating. Why did they bury them? Sounds like it would be more educational to show students the set up and also quite a bit cheaper not to bury I’d have thought?

Some time ago perhaps pre covid, got poor memory, but I was enthusiastic about spinning wheel storage.

I think it was somebody from avinoics that brought me down to earth. If say at 32 000rpm material failure should occur you would not want to within a mile of such a thing.

Having the above underground could be a nice safety thing. Will see if I can find the article.

Because if they happen to break (unlikely), you have four tons of Thor’s Hammer style wreckage.

Correct me if I’m wrong:

1: These flywheels spit out a flat 8kw of power for four hours.

2: They require a 150ish cm wide hole in the ground, and have a lid that protrudes a foot or so.

3: They’re something like 48 grand.

4: Besides changing the bearings every decade, they’ll never degrade, or otherwise break.

Why aren’t we using these things on a utility scale?

Yes I think Mr Brakels can’t just tease us all with this tiny article. He needs to research much more about this for us.

This is erronious:

“Some of the advantages of flywheel energy storage systems is they are low maintenance, there’s no fire risk, they have a claimed service life of 20 – 30 years and can be easily recycled.”

Technically, all they need is an overhaul, new bearings, brushes, vacuum seals, relays etc, etc.

AND as a Mr. Know It All, on the subject, the reasons why the flywheels are NOT really huge, and fast(ish) spinning, is because of INERTIA and the things that most people never think about, because it’s not terribly obvious.

I shall explain.

If you get a big bicycle front wheel and hold each end of the axle, and then get a friend to spin the wheel while you hold it, OR even better and potentially very dangerousness, get a compressed air gun and aim it at a very shallow angle into the treads and speed the wheel right up (balanced bicycle wheels anyone?) – AND then if you try to steer the rapidly spinning wheel (I forget the names) the gyroscopic forces will resist the turning, and they will feed back the resistance to your hands, and do funny things – which if the wheel is spinning at 160 Kmh, might result in you losing your fingers and half a hand etc.

This is why bicycles are held upright and they LEAN into corners as opposed to turning around into corners (don’t nit pick – you know what I mean).

So when you get REALLY huge and fast spinning fly wheels – which contain enormous amounts of gyropscopic energy – this is really great – but the EARTH it is on, changes it’s orientation through 360* Degrees every 24 hours.

This is just like the “Penny Farthing” bicycle FRONT wheel in a vacuum spinning at 10,000 RPM or 15,000 Kmh around the circumference, while you hold onto the axle with both (?) hands, while you stand there in your space suit in the earthly vaccum too.

This issue is the limiting factor in flywheel based energy storage systems.

So until someone builds a HUGE flywheel in a planetary multi axis gyroscope thing, so it rotates freely (say pointed at the sun), no matter how far the earth has rotated out of alignment, and they have figured out how to speed it right up and tap energy from it, and to stop the cables tying up in a huge knot, then all will be well.

Also there is a law of inversion in that the FASTER the flywheel rotates, the smaller it needs to be in diameter, to contain the energy, and the greater the need for higher strength materials that get used in it’s composition.

Think carbon fiber in a small flywheel, and not steel plate on a large flywheel….

I seem to recall a demonstration suburban bus (in Germany, perhaps) using a high speed vertical axis flywheel (under the floor) for drive – and it may have involved carbon fibre together with steel (for inertia AND strength). Some years ago.

Regenerative braking meant a lot of stop-start driving was made much more energy efficient – great for a bus duty-cycle.

In fact, we did an evacuated flywheel design as a project during final year Mechanical Engineering at Uni – around 1974.

What was old, is new again…

Precession…

“This is why bicycles are held upright and they LEAN into corners as opposed to turning around into corners (don’t nit pick – you know what I mean).”

I am going to nitpick because no, this is not why bicycles are held upright.

While present, the gyroscopic effect of bicycle wheels rotating at typical riding speeds is tiny and far too small to have much steering or stability impact on the mass of a bike and rider.

Bicycles stay upright because their geometry creates very stable steering dynamics. A moving bicycle which leans over causes it to turn into the lean, which then causes the bike to sit back upright. It’s a self correcting stability built into the geometry which has all but nothing to do with the wheel’s gyroscopic effects.

Hi Shane

So – if you mount the flywheel (underground, if you like), with its shaft axis parallel to the earth’s spin axis – named an ‘equatorial mount’ in astronomical telescope parlance – the the precession effects of the earth’s rotation are totally eliminated. And, no gyroscopic mount would be required, and the cables wouldn’t tie themselves into knots.

Then you only have precession effects from the rotation of the earth (and flywheel) around the Sun. As this is quite slow, I’d think the forces involved (to react against this precession) are quite low – and probably near-negligible compared to the gravitational (weight) forces on the bearings.

Precession forces are proportional to the rate of change of the spin axis direction. Having the flywheel axis vertical in a bus, would allow it to turn corners!

Just a thought!

Re vertical axis in bus…….However (!)if bus was travelling quite quickly (say > 80kmh) and went either OVER a very sharp crest, or DOWN through a very deep dip in the road then the gyroscopic forces would tend to make the bus roll over 🙂 – or have I forgotten all my physicss/mechanics/laws of motion ??

(I’m sure I remember a story — probably apocryphal — about this happening in practice sveral decades ago in an experimental vehicle; was resolved by using TWO vertically mounted, but counter-rotating, flywheels.).

Or maybe it was just an engineering “in” joke!!

I’m sorry Shane but I have to say, are you serious?

Do you know what a frame of reference is?

You understand that the flywheel and the ground moves with the earth don’t you?

The rotation of the earth is absolutely not an issue. My goodness.

In 1972, one of my engineering lecturers at QIT in Brisbane was keen to experiment with a flywheel dragster.

Here’s one that’s been around for a while:

https://www.hydro.com.au/clean-energy/hybrid-energy-solutions/success-stories/king-island

Hi David

Just looked at the widget just now, near midday WA time.

Interestingly, wind was OFF, battery was OFF, and solar was showing as producing 1% of demand (although this is a ’rounded’ figure – true figure was nearer 0.6%).

I hope they have an efficient diesel, as this was producing 99.4% of demand. Maybe they use the waste heat (not shown)?

The flywheel seemed quite effective at maintaining grid frequency at very close to 50 hertz – although it was shown absorbing 65 kW continuously (but the numbers didn’t ‘add up’, so I guess there is some form of calibration issue somewhere).

I think they are going to need to install a whole lot (order of magnitude) more wind and solar capacity, and a much, much bigger battery – it seems the flywheel was acting more as FCAS, rather than as bulk storage.

Amber Kinetics has a good web site which clearly explains their choices in materials and design elements. Sure super speed flywheels are made and have been used have a look at the Beacon flywheel information where carbon fibre units operating at very high speeds let go. Amber picked a good grade of a common material (steel) then used magnetic suspension to take most of the axial loads meaning simple bearings could be used to keep the unit vertical and deal with the precession issues. The choice of simple materials and keeping the units modest in size certainly does make the possibility of mass production of the units possible. This could lead to grid scale installations.