Dye Sensitised Solar Cells

By Finn Peacock, Chartered Electrical Engineer, Fact Checked By Ronald Brakels

It is a completely different approach to solar power that requires no silicon whatsoever. Instead, dye sensitised solar cells aim to mimic how plants create energy from sunlight.

You can probably remember the concept of photosynthesis from school, where plants use chlorophyll to convert sunlight into the energy they need to grow. Well, that’s the principle that these solar cells use.

Dye sensitised solar cells use dyes or ‘sensitisers’ to convert sunlight into electricity.

The solar cell is made up of a light absorbing dye and a metal oxide semiconductor – which carries the electric current.

Electricity is created when the dye is hit by solar radiation and gets energized. The dye’s energy flows from the dye to the metal oxide surface creating electricity.

Making a dye sensitised solar cell can be almost as simple as filling a specially coated plastic pouch with the right mix of liquid chemicals and connecting a pair of wires. So you can imagine the potential these things have for making solar incredibly cheap.

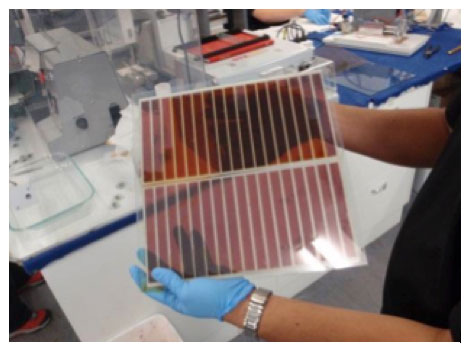

Here’s an example of a dye sensitised solar cell made by Dyesol:

The brown bits are the ‘pouches’ of dye. As you can see the cell itself is semi transparent, which opens up a lot of possibilities for designing these things into buildings and even replacing windows.

Efficiency

Aha! I hear you cry. But surely the efficiency of these cells is tiny compared to conventional solar?

Well Dyesol are reporting efficiencies of up to 11% for their cells – which is better than many thin film solar panels on roofs today!

Advantages of dye sensitised solar:

- The capital cost to make them is estimated at a third of conventional solar panel manufacturing equipment.

- The cost of the materials to make the cells is very low compared to conventional solar.

- Their output is very stable under various light conditions. E.g. if a cloud passes the power won’t dip much. Compare that to crystalline panels whose output will instantly drop to almost zero if a cloud comes along.

- The angle they are installed at is not as important. So if you want to integrate it into a window, you’ll still get plenty of power. Compare that to a conventional photovoltaic solar panel will lose almost half its potential power output if placed vertically.

- They are made of environmentally friendly materials compared to the toxic brew required to make conventional solar panels.

So why haven’t dye sensitised solar cells they taken over the world yet?

Good question! Although dye sensitised solar cells with good performance have been made in the lab, it is another thing altogether to scale this into an industrial process that churns out millions of solar panels that are:

- Durable

- High Performing

- Cheap

For example, there is a huge solar panel made by Dyesol installed at the CSIRO in Newcastle. It looks really nice, letting dappled light into the entrance atrium.

Unfortunately it produces almost no electricity! The researchers quickly discovered that such a big dye sensitized solar panel just wasn’t durable enough in the real world. But, hey, it was installed almost 10 years ago, so hopefully the technology has come on leaps and bounds since then.

That is the challenge for the next few years. If companies like Dyesol can successfully industrialise their processes to mass produce these solar cells and fix their durability issues, then I don’t see any reason why they won’t be wildly successful.