With the launch of the Federal Government’s Cheaper Home Batteries Rebate Scheme, we’re about to see a serious uptick in grid-connected battery installations across Australia — and authorities will be ramping up inspections to make sure these are done safely. Here’s two key tests installers must undertake on new systems.

With the launch of the Federal Government’s Cheaper Home Batteries Rebate Scheme, we’re about to see a serious uptick in grid-connected battery installations across Australia — and authorities will be ramping up inspections to make sure these are done safely. Here’s two key tests installers must undertake on new systems.

The federal rebate is great news for consumers and even better for the stability of our national electricity grid — but it also brings a big responsibility for installers.

The Clean Energy Regulator has flagged that an inspections program will ramp up after the July 1 start date, while the ACCC and state consumer bodies are on high alert for dodgy installs.

Here’s the truth: even though battery installs might seem straightforward on the surface, there are a few critical tests that absolutely cannot be skipped. These tests aren’t just box-ticking—they are safety-critical. Get them wrong, and you could end up with a system that’s not just non-compliant… but downright dangerous.

Let’s talk about the two mandatory battery installation tests1 that every installer needs to understand — and perform — every single time.

Why Battery Safety Tests Are Important

It’s worth explaining why this kind of testing matters for anyone getting a battery installed.

When a battery is added to your solar system, it’s not just about storing energy — it’s about doing it safely. These mandatory tests are designed to make sure your system doesn’t create hidden electrical faults that could damage equipment, stop safety switches from working, or even create an electric shock risk.

A good installer will:

- Test that electricity is flowing along the correct paths when the system is in backup mode

- Confirm that safety switches (RCDs) still function correctly, even when the battery is powering your home

- These checks don’t take long, but they are critical. If you’re having a battery installed, it’s reasonable to ask your installer what safety checks they’re performing — and whether your system has been tested in both normal and backup modes.

Two Key Tests

Whether an installer is new to battery installs or has been doing them for years, these two tests are non-negotiable:

- Testing for Parallel Earthing Paths

- Confirming Neutral Continuity

Both tests must be done in backup mode, and both are vital to ensuring the system performs safely under fault conditions.

Test 1: Checking for Parallel Earthing Paths

This is a key test that many installers still miss — or misunderstand.

When some inverters switch into backup mode, the way they handle current can change. In certain setups, active current from a load might return to the switchboard via both the neutral and the earthing conductors. That’s a major red flag.

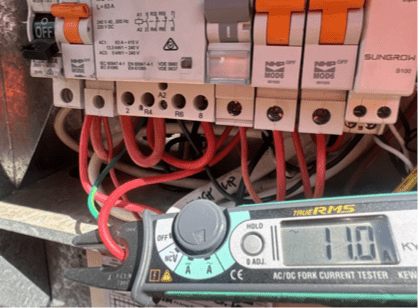

System in back-up mode with a load of 11 amps measured on the active conductor.

Any current flowing in the earth conductor indicates a parallel earthing path — a situation that could be unsafe and result in defect notices or worse.

How An Installer Should Perform the Test:

- Put the inverter into backup mode (confirm it’s not feeding from the grid).

- Apply a decent load — such as a toaster or a hairdryer. I use a purpose-built hairdryer tester that draws around 8 amps.

- Clamp a meter on the active conductor, then on the neutral conductor.

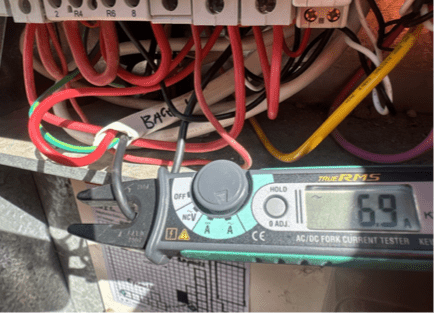

System in back-up mode, load of 6.9 amps measured on the neutral conductor. Significantly less than the active conductor – this is now concerning.

- The installer should see equal current in both.

- If there’s less returning through the neutral, the balance is likely going through the earthing conductor — and that’s a serious issue.

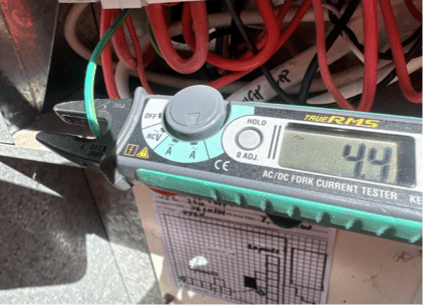

System in back-up mode, load of 4.4 amps measured on the protective earthing conductor – red flag!

Note: A small load (e.g. 1 amp) won’t show enough variation to reliably detect faults. Use something drawing 8–9 amps for a meaningful test.

Test 2: Ensuring Neutral Continuity in Backup Mode

This test confirms that the neutral conductor in backup mode is continuous and connected to the main neutral bar. Without it, the Residual Current Device (RCD), which serves as a safety switch, may not function correctly during a fault — posing a significant risk.

Sometimes inverters switch the neutral out in backup mode, especially if incorrect country settings are used or the system hasn’t been fully configured. If the neutral is missing, the RCD may not trip when it should — leaving parts of the system unprotected.

How I Do It:

- Confirm the system is in backup mode.

- On a backup circuit, place one probe of a voltmeter on the active conductor (load side of the RCD or circuit breaker).

- Place the other probe on the main neutral bar.

- System in back-up mode, measurement of 230 volts between the back up active & the main neutral bar – neutral continuity confirmed.

- The installer should see a voltage reading around 230V. If not, the neutral may have been switched out.

This test proves the RCDs on the backup circuits will still operate under fault conditions. Without that continuity, your safety systems simply won’t work.

Why Installers Need to Get This Right

With battery uptake growing fast, we can’t afford shortcuts. These tests are simple, quick to learn, and mandatory.

Yet I still see installs where these checks are either skipped or misunderstood. That has to change — especially now, with thousands more systems about to be installed under the new rebate program.

Learn to Test Battery Installations Properly

To help support the industry through this shift, we’ve released a new course at Southwell Solar Training called Testing a Battery Installation, which covers:

- The tools required to test safely

- Live demonstrations of both critical tests

- A side-by-side comparison of compliant vs. faulty installs

- Real-world examples of what can go wrong — like current flowing through the earth (a clear danger sign)

If you are installer wanting to find out more on this course, take a look at our Southwell Solar Training website — we have more battery guides for installers on the way.

If you are homeowner wanting to know what you can do to maintain your battery once its installed, check out the SolarQuotes guide to living with a battery.

Battery Safety Isn’t An Optional Extra

Battery installs are booming — and that’s exciting. But the basics still matter. Safety and compliance aren’t optional. These two simple tests make the difference between a reliable battery system and one that could put people at risk.

Get them right. Every time.

Footnotes

- outlined in AS/NZS 4777.1:2024 ↩

RSS - Posts

RSS - Posts

Is this an increase in inspections starting from July, or do you mean the regulator has had no inspection regime in place at all, and they are only getting around to set something up now?

Pretty poor if it is the later.

The Clean Energy Regulator says that this change is in relation to battery installs falling under the SRES once the rebate begins, so the inspections would partly be to ensure the system is eligible.

Even though I’m off-grid, so no corporate network compatibility issues, my installation was promptly inspected 1.5 years ago. I though the quick earth & neutral tests I saw were not a lot of testing, but now it seems that it’s all that’s required.

The only issue that surfaced here was an inadequately tightened lug-bolt on a 250A DC circuit breaker, detected by the customer’s smell test. (That can be hard to otherwise test for.) The breaker was replaced. Good safety suffers no compromise, but sometimes it is only alertness which catches a problem before there is smoke.

As battery sizes grow, and fault currents can rise into the tens of kA, these domestic installations approach industrial-level risk on the DC side. I would not be disappointed to see inspection of DC HRC fusing & breakers. Maybe also confirm DC, not AC, breakers are used? Just a few quick tickboxes, but 3 times $2.3B buys a lot of opportunities for missteps, some due to unfamiliarity.

Would this be common knowledge for established local installers? Or do I need to micromanage my installers so that they do these tests. If so, shouldn’t this be distributed to installers in some sort of safety bulletin rather than to a consumer focussed website? I don’t want to annoy my installers unnecessarily so that they think I am a know-it-all problem customer.

We’ve published this not only for homeowners to be across what their installer should be doing (yes, it might mean being a bit of a pest, but better that than having problems with your battery down the line), but also for installers, many of whom read our more technical stories.

An experienced installer should be across what to do, but the rapid expansion of the battery installation market in the coming months could see a lot of inexperienced operators join the fray.

Your pic of the 6.9A in the neutral is described in the text as the active

In backup mode, since it’s not ground return, wouldn’t you have to touch both live and neutral to get a shock?

super work Pat & Max, thank you. it is very pertinent to keep the key concepts front of everyones mind, cheers

The pix of the burned LG NMC battery is scary ! Wish I knew more about it?

I tested them in the US and one of their big failures for us was the RESU 10 battery switch is under a bolted down cover that could take 15 minutes to remove. On mine, I cut an opening in the cover to enable me to shut it down.

An external DC shut down still might not shut down an internal battery failure if it were severe. I am surprised that they are the only ones who do this!

Dave Angelini offgridsolar1.com [email protected]

Thanks Pat – great work.

Any future release of this critical safety steps would not be alarmist to link to the horrible “pink batts” fatalities for the reasons you allude to.

The law of big numbers. Fires and possibly lives lost can occur.

New entrants will be installing. Please prepare a pdf checklist for all installers and owners. A checklist I “must” send to my home and contents insurer. Perhaps even pass to the regulator who might just be risk averse enough to release with their logo!

Steve