It might not appear to be earth-shattering, but a malfunctioning hot water storage tank may just shatter your walls. Here’s how a perfect storm (or an unlicensed idiot) can do real damage.

It might not appear to be earth-shattering, but a malfunctioning hot water storage tank may just shatter your walls. Here’s how a perfect storm (or an unlicensed idiot) can do real damage.

With household electrification gathering pace and hot water heat pumps on the rise, we’ve been vetting plumbers to join our network.

Having reviewed Australia’s plumbing standards, there have been a few things we’ve noticed that vary from place to place and plumber to plumber.

Obviously, when you turn the tap on there should be water gushing forth steadily, and you’d like it to be hot.

However, there are quite a few rules to observe when installing the technology to make this happen safely.

The Rules Are For Safety

Legionnaires’ disease is a risk people have learned to live with, but minimising exposure with careful management is written into many laws.

Cooling towers need to be sanitised with chlorine, but hot water services are a different kettle of fish.

To kill any potential legionella, your entire storage tank needs to be heated to over 60ºC every day.

Many hot water thermostats are set to 75ºC in order to store more energy. There’s more standing losses, but this allows more showers from the same-sized tank.

Solar thermal hot water services, like the classic Solahart close-coupled units, can boil in summer (a fact my dear mate Derek loved because he could sterilise home brew bottles straight from his tap).

Scalding Hot Is A Real Danger

However, building standards call for water delivered to outlets in your bathroom to be no more than 45 or 50ºC to prevent burns.

This is normally done with a tempering valve that mixes cold water into the hot feed as it leaves the tank, so the whole place has “hot” water at a moderate temperature.

This is a model heat pump install with pipes lagged and valve cosies everywhere. The pink arrow shows where the tempering valve is adjusted. Image credit: Brisbane Solar Repairs

Technically speaking, laundry and kitchen areas can have higher delivery temperatures, so they can be fed with an untempered line, but in practice, this seldom ever happens.

What does occur regularly are complaints about tepid showers, because long uninsulated pipes inside the building dissipate precious heat before it reaches the bathroom.

The upshot is that people rip the cover off the tempering valve and crank it up to get hotter water through, which sort of defeats the purpose.

Doing it properly means making the tempering valve readily accessible in the wall of the bathroom, as they do in hospitals, so the water is only tempered once it reaches the destination.

Houses Aren’t Bomb Proof

The explosion risk mentioned at the start of this article can emerge from a malfunctioning pressure relief valve. A Boiling Liquid to Vapor Explosion can do real damage.

When this tank let go, the results were spectacular.

You should go out and operate the valves every three months to make sure they’re clear and not stuck shut.

And the law says that when you do this maintenance, the hot water discharged from the tank must be visible to you, but not directed at your body.

Of course this didn’t apply to my high school, where we used to reef the copper pipe around to point at the next hapless kid who rounded the corner of the toilet block. Operating the valve was kind of a fixed artillery version of a water pistol.

Drips Are To Be Expected

Your hot water tank has a non-return valve on the inlet, so if the house is abandoned or power switched off, you won’t be able to backfeed a tank of legionella into the rest of the building or neighbourhood.

When this tank is heated, the water expands and so the pressure relief will allow a small amount to bleed off. Now if there’s a lot of dissolved minerals in the water, (ie in South Australia) crap can build up and cause it to stick shut or dribble continuously, so it’s recommended the valves are replaced every 5 years.

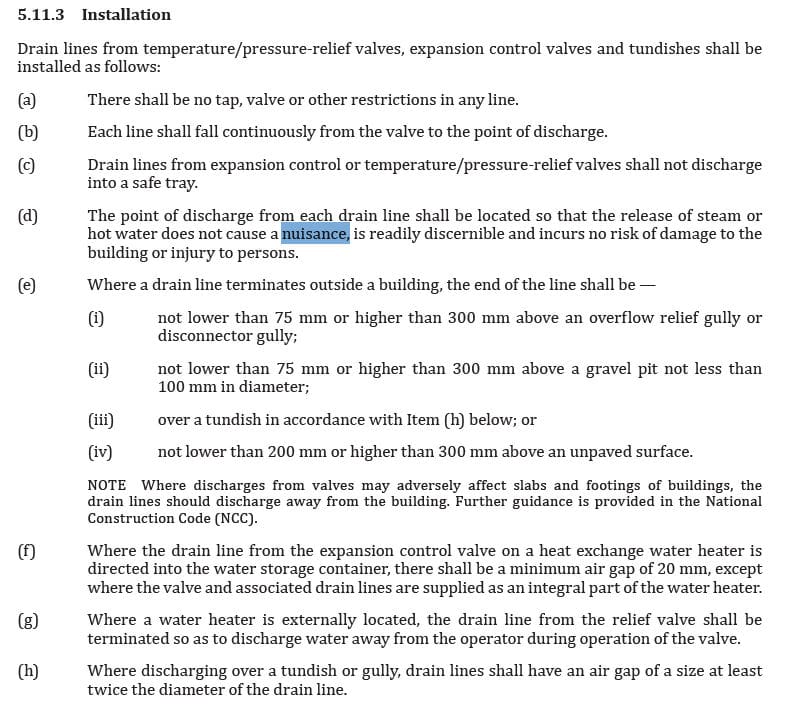

The main point is this; pressure relief valves will drip, dribble or gush in normal operation and they have to be drained properly.

- If left to drain right next to your foundation, they’ll potentially undermine your building.

- Dripping on a concrete path can grow slime and create a slip hazard.

- At worst, a solar hot water unit may blow off 300 litres in one cycle, so piping must withstand boiling water.

- Rules vary by state but drains must go to an “approved point” which may be a gravel pit or gully trap connected to the sewer.

Drain lines for close coupled solar hot water units must be copper, they’ll melt plastic downpipes and PEX plumbing alike.

Not All Plumbers Take This Drain Requirement Seriously

Tap water in South Australia is generally very hard, so local enforcement is a stringent pain in the arse. The high mineral content means hot water services must have hot and cold pressure relief valves fitted.

Observing the letter of the law can mean digging a pipe right around a house or spending thousands on a custom-engineered solution.

This water heater in SA has a tundish (highlighted in green) but the grey condensate line is haphazardly placed. The pink highlights where there needs to be pipe lagging to make it compliant.

Other states will allow drains to go into the soil, provided the outlet is between 200 & 300mm from the ground. Interestingly, plumbers tell me the pipe has to extend a metre away from the building, but it seems this is lore, not law, as the technical evidence doesn’t seem to exist.

It’s all about how you define a nuisance. Is it the hot water hitting your feet or the plumbing rules themselves that annoy you.

Interpretations Vary

Having spoken to inspectors from South Australia, Victoria, ACT and Western Australia – and finding that Queensland only have limited support line hours – I’m disappointed that NSW can’t even respond to an email.

What I have confirmed is that the rules are enforced in different ways, so you may need to check with local authorities.

For example, Victoria has a checklist and not one but two complimentary guides on drains; and the inspector I spoke with doesn’t agree with all the images in the pamphlets.

And if you have a tank inside a cupboard or ceiling space where it can’t be seen readily, it must sit in a “safe tray” so that any leaks will be caught and drained away before they pour through the ceiling.

While the plumbing standard of AS3500 says that pressure relief valves should not drain into a safe tray, some deem it acceptable if the pipe coming from the pressure relief sits straight over the safe tray drain, using the whole tray as an oversized tundish.

The Rules Were Set In 2014

While it might seem pedantic, we like seeing nice work which isn’t going to cause grief after installation. We’ve got skin in this game so there’s no reason not to follow the rules we’ve touched on here, unless you’re the kind of slacker we don’t want at SolarQuotes.

We’ll likely touch on some more in following episodes, like: what is a valve cosy? And where does pipe insulation go?

In the interim, read our deep-dive explainer on hot water heat pumps to see if they’re right for you.

RSS - Posts

RSS - Posts

I now have instantaneous gas hot water but there’s next to no lagging on the hot water pipes. Most of the piping was installed with the original in-roof space storage hot water in the early 70s. I know I should climb into the roof space and fit lagging but these old bones don’t like clambering around up there. I don’t think the ROI is there to have a younger man do it for me.

The OTC RB?

Licensed plumbers can be pretty bad too. I bought a ten year old house with a $!0,000 hot water service where the huge tank feeds up to the roof to a solar collector and back to the tank. A massive amount of 3/4″ copper goes through the ceiling.

So one day we have a water leak in the ceiling and find it is from a compression joint on the solar collector which is outside on the roof not in the ceiling.

The bodgy workmanship was

(1) No boot where the pipe went through the metal roof, must have been 1 short so they siliconed it.

(2) They must have not had any saddles that day as all the pipe inside the ceiling was duct taped to the trusses.

So the duct tape failed and put angular pressure on the compression joint and it failed.

Luckily we caught it in time and it cost $150 for a plumber to fix it and less than $50 for me to fix the plaster and paint.and put many saddles where they should be.

Hey Doug at least you got duct tape. 25 years ago I paid a plumber to install an instantaneous gas hot water service on an outside wall of my flat to replace a day rate electric hws which was in a cupboard over the very small fridge space in the kitchen. The hws was installed crooked on the wall & when I complained I was told someone must have swung on it after the plumber left. The copper pipes for the new hws were slung across the dirt under the floor. Water hammer was so bad the night shift worker in the next flat threatened that he would have to move at my expense if I didn’t stop the noise. I asked the plumber to return and rectify the problem but I ended up crawling around under the floor myself to clip up the pipes.

Interesting how we’re now ripping out gas and going back to all electric again.

Hi Julie,

The thing that’s changed is price.

Gas is growing ever more expensive, even without a price on it’s environmental damage.

Electricity is no longer charged at flat rates (once you have a smart retail meter) and in the daytime it really is cheap now.

Finding *compact* hot water units for flats and balconies is going to be the next challenge.

Here I have the tempering valve directly on the HWS outlet, as the hot water piping is red PEX, and there’s an in-flue heat exchanger on the wood heater. I.e. boiling the HWS can easily happen in the depths of winter. It is therefore also mandatory for the tank to be vented to atmosphere, i.e. not pressurised. That necessitates a header tank in the roof space, and a pressure pump for an adequate shower. (Speed control on that pump is handy, as too much pressure causes the kitchen sink tap to shoot water down around the bottom curve of a wineglass and back up your nose.)

Placing the HWS indoors, one wall thickness from the shower, avoids heat loss in pipes – and the tank’s heat loss is recouped in room heating. The tank has an internal heat exchanger coil to separate vented heat-store water from the consumed water. (Not cheap, but works well.) I do need to lag the woodheater heat exchanger, as it loses heat in a few days. (Some cedar staves, I think.)

Hi Eric,

I think I need some photos of that setup. Sounds excellent !

Hi Anthony,

I’ve sent three photos, hopefully illustrative. The wood heater and HWS are located in alcoves in an internal masonry wall, the idea being to provide a bit of a heat bank, holding lost heat from both sources, in addition to breaking up the expanse of plain plaster walls.

The strawboard ceiling and carpet provide delightful acoustic damping, useful if you’re sensitive to such things … or have young kids, and the weather doesn’t allow throwing them out into the paddock till teatime.

P.S. The whole solar setup is described in a 4-page article on p74 of the Jan-Mar 2025 issue of Renew magazine, still available on-line for anyone looking into alternative energy options. (It is off-grid, and a bit overdone for redundancy and winter yield, so not all needed for most use cases.)

Below is what an AI generated response from an SEO engagement bot looks like, don’t fall for it – admin

Your post has made one thing very clear to me: why solar water heating with valve drainage is important, especially for people who have any solar or traditional water heating systems. I truly liked that you highlighted not only the technical details but also the safety and compliance aspects, which many homeowners completely overlook. It is surprising to see where valve drains should terminate in various states of Australia — in the floor, in an approved gully trap, or at a specific discharge point — and how the need for copper lines in solar thermal systems caused by high temperatures can vary. I’m looking forward to future posts in this series, especially on related topics like valve insulation and compliant valve cosy installations.