Electrical conduits are the tubes used to protect and route wiring. Get them wrong and you’ll make roof spaces even more unsafe than they already are.

So what does good conduit work look like? Read on while we peek above the manhole.

Why Is Electrical Conduit Work Important?

Conduit work can look pretty ordinary, but it’s a matter of function over form.

What we’re installing is mechanical protection around the wires, but getting different arrays on different roofs connected while simultaneously running everything inside plastic pipe can be a proper nightmare.

It’s plumbing with material that refuses to flow.

Out Of Sight And Out Of Mind

We need to acknowledge the reality of roof spaces. Unless it’s a nice clean new build, on a cool day, without ceiling sheets installed, you’d have to be out of your mind to think it’s a good work environment.

Confined spaces, heat, splinters, fine dust, rat droppings, itchy insulation, snakes and possums are just the start. When you’re inside the roof your mind has to be alive to risk. In fact it’s illegal to enter a Western Australian roof without first turning the power off.

To get the claret flowing, nails and nail plates can slice you open while furring channel (the modern excuse for ceiling joists) are littered with needle point gyprock screws.

You have to move without damaging fragile finishes, or fragile air conditioning, not forgetting the chance of falling through the ceiling when your foot misses a joist.

Swing over the collar tie, avoid the duct, commit weight to the beam, slip off the ceiling joist and BANG

Rules For A Reason

Back when I was limber we ran black solar cable clipped straight to the timbers. Using standard white TPS wiring was prohibited unless you put it in conduit, which was rightly viewed as a massive pain in the backside.

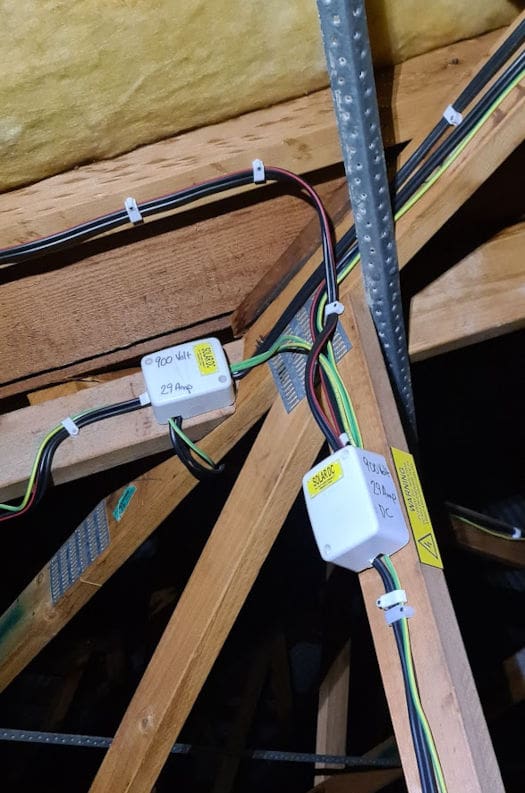

This was compliant in 2013, with a potential here of 900Volts

Enclosed in conduit from 2014 onwards, similarly complex array wiring is more challenging to install

Changes to solar installation standards mandated conduit for everything because authorities were afraid DC solar wiring could be damaged, either by roof possums electrcians, or the rodents TV technicians could kill themselves cutting the wrong cable.

The black twin is a satellite TV cable that looks frighteningly similar to DC solar cable, so we put the very spicy voltage inside a uPVC “solar” conduit.

Steel Frames Are The Worst

Not only are they a thermal disaster in insulation terms, lightweight steel ceiling joists can’t support your bodyweight. So you have to lumber from truss to truss, it’s difficult as the edges are sharp and they’re 1.2 metres apart.

You need to be a contortionist with a bullocks hide to navigate the small spaces and sharp edges of a cheap tin truss roof.

One of the worst places I ever installed on was a newly constructed house on a now typically narrow block. The skinny roof was low and the trusses too tight to pass a body through. They barely fitted the ducted air con unit or the ducts themselves.

Working through the manhole, these conduits are sitting on the ceiling, however they’re deemed compliant because there are external isolators on the roof.

We resorted to keyhole surgery. I stood on a ladder in the manhole and pretended I was a periscope, two tradies threaded a length of conduit in from the outside. I yelled instructions to twist the rigid plastic pipe, so with a slight bend on the end, it would “steer” through the obstacles.

You have to disassemble these houses to work on them. With 6 roof sheets removed, one pushing, another manipulating a third calling instructions we got conduit through it.

The Key Is Adequate Support

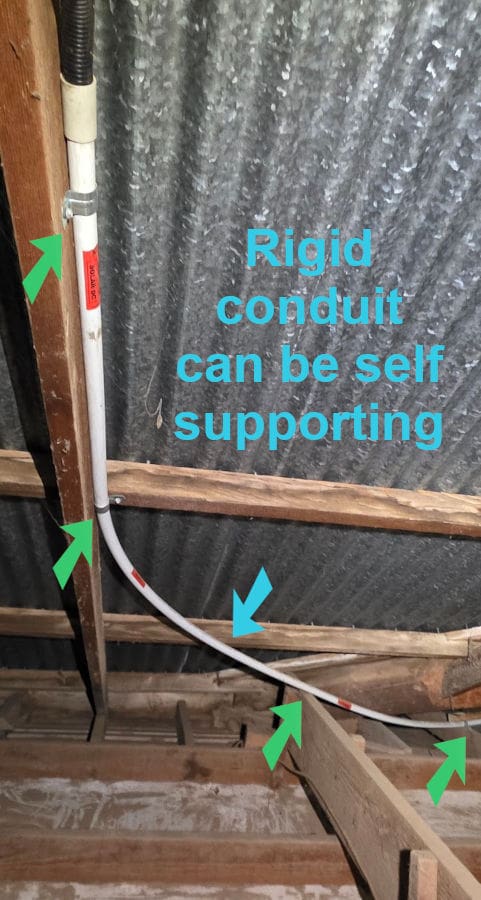

Electrical installation rules stipulate wiring must be installed free of external stress or physical strain and given adequate support. While manufacturers specify things like bending radius on cables, the standard doesn’t have hard rules or fixed measurements, determining adequacy is down to your licensed electrician and their judgement.

Well labelled, well supported (green arrows) and well away from the ceiling until it meets the eaves. This ticks the boxes.

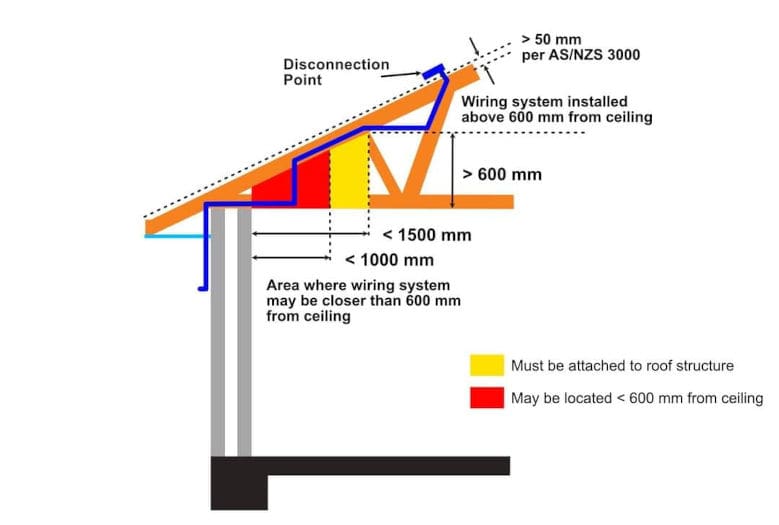

The conduit arrowed in pink should not lay on the ceiling, especially when there’s more than 600mm of headroom available, defining this space as accessible under AS3000

Duct tape shows the compliance and care factor here is zero.

Basically the people doing the work install what’s needed and certify the wiring won’t be damaged in service. In a nutshell it shouldn’t flap around, get in the way or get broken by foot traffic.

Foreground shows a timber installed to protect conduit from clumsy feet

The regulations do set out rules for routing conduits though. They must not be laid across the ceiling but rather should follow the rafters. The reasoning is that fire fighters often need to spray water into the roof. When they ram a hook through the gyprock and tear down the ceiling, there must not be DC solar wiring in harms way.

The blue trace shows the approved path for DC solar conduits where no rooftop isolator is used.

This conduit is labelled, supported and secured, but it’s too close to the ceiling

This conduit is too close to the underside of the roof, plus it’s been split open, taped up and glued into the wrong sized fitting. They tried but failed here.

Underneath this house, there’s no DC labelling but the conduit is also too close to the floor (shaded pink) Again this is a basic AS3000 wiring rule violation.

Electricity And Water Don’t Mix

Despite this incredibly common expression, electricians are inexplicably keen to bore holes and pipe condensation straight into inverters and switchgear. The rules even acknowledge this, specifying “drain valves” must be put into the conduit system at the lowest point.

I can’t think of a reason why anyone needs to put plumbing into electrical equipment, it’s ludicrous.

Unless we seal wiring systems, and pressurise them with inert gas, there will always be air present and air carries water.

The answer is to use conduit as intended, as mechanical protection, while sealing the inverter or isolator as the manufacturers designed, tested and rated them. Tune in for the next exciting episode when we explore condensation.

If you have any technical queries about the tiny details of your solar power system, consult our FAQ section. It’s full of real world questions and the answers we’ve found for them. There’s lots of links to blogs like this one too, so dive in and find yourself and answer in your own time.

RSS - Posts

RSS - Posts

This reads more like a “what not to do” for the cowboy installers.

Theres not much in the thread that the average homeowner can take away.

Maybe after the fact, seeing that their budget buster deal carries with it a half assed install by cowboys. Only to realise when you pay peanuts, they’re not coming back to rewire their garbage.

Reader.

Dodgey workmanship stems from underpaid subcontractors.

To avoid the above.. don’t roll the dice on a car yard salesman promising you the best at below market price.

*You get the workmanship you deserve.

Owner-builders take more care regarding access. My 25m long build has a lengthwise walkway, made of three parallel slightly spaced runs of 90x45s, so you can nearly jog through the highest gap in the trusses – though tall folk have to stoop a little bit. And there’s a manhole at each end, so you don’t have to go all the way back.

Admittedly, I still used a pair of planks on the ceiling joists when roaming off-axis. Place for tools, materials, and your bum, when working makes it a lot easier.

I also installed the ceiling insulation on runs of plasterer’s joint tape, stapled tautly under the joists. Quickly and easily shoving them up from below beats the heck out of wrestling with them in the ceiling space. A batt squeeze-fit between joist is needed anyway, so there’s little increased risk of gaps. (With care)

Ducted aircon isn’t worth it, so skip the ducts, I say. (Three split systems do it all here – no ducts – no roof horrors, installing, or later.)

yeah, then i think of my electric light cables just loosely laying in my roof cavity with no protection at all.

Hi Andrew,

If there’s less than 60cm headroom it’s considered inaccessible. ie you don’t have to protect it from foot traffic so they just get thrown in, however it doesn’t mean they shouldn’t be rated for the job in terms of current carrying capacity and ability to dissipate heat.

#600 mm headroom# I think? 🙂

Precisely Richard,

Thanks.

I have an older home and said to a sparky mate that I’d love one day to get a full check of the wiring, and replacement as necessary.

He said “good luck finding anybody who’ll do it”. Said with the desperate demand for trades now people are getting very picky and refusing to do some of the harder things. Some restrict themselves entirely to new-builds.

Hi Nick,

There have always been fussy bastards who don’t want to do the dirty work. I ran into a lot of them doing new build roof purlins. Plumbers who refused to do drains, crapenters who refused to do rennovations, roofers who only do new build.

In a lot of instances you don’t want them because if they know their knitting then they’re good at just that and repairs are a different skill set. The ones who can cope with thinking outside the box are better at old places and deciphering what the last bloke did.