Think about the tin roof over your head. Its primary function is to keep the rain out. Now picture putting holes in that tin sheet for a fat bundle of cables. It’s risky if not handled properly.

The weakest point of any solar installation is where the wiring enters the building. Wiring penetrations are a craft all of their own but some examples I’ve photographed are laughable. Join me as we have a giggle and learn about the worst ways of running wiring into an iron roof.

As an automotive tradesman working to a hair’s breadth tolerance, I’ve always marvelled at how houses stand up despite what builders do to them.

As a licenced builder, supervisor and roof plumber, I was impressed that electricians created so few leaks. I suppose it’s their one failing; despite being smarter, faster, slimmer, & better looking than plumbers, some sparkies don’t understand plumbing well enough to keep ceilings or even electrical things dry.

Silicone Is The Savior

I lament the vast bulk of trades have no clue about how my old boss used nails, flux, and solder to fix roofs.

These days, with a caulking gun and tube of “No More Skills” nothing has to fit properly because modern sealants cover a multitude of sins.

I’m not saying we need to revive the art of sealing things with molten metal, but it wouldn’t hurt if people understood the beauty of simplicity, before designing a box gutter.

Follow The Roofers’ Mantra: Put The Hole In The Best Place

It’s so simple when you apply thought, yet some trades can work for years before running into a pedant like me who’ll demonstrate precisely how it’s done.

Imagine you’re poised to pierce a pristine roof with a huge holesaw.

Stop and think: would water trickle, or pour straight through if you forgot to put sealant on it after smoko?

This example below really tested my patience. The conduit is placed correctly in the high flute, but the 4 screws in the down flute are not mechanically waterproof.

How to ruin a new roof. Drive screws through the low part of the profile where the water runs straight over them.

Holesaws Shed Hot Shavings & Rust Roofs

A toothed blade makes an awful racket as you tear through a 0.4mm metal sheet. The noise makes me wince, especially when I know the drill operator has no mechanical sympathy and no cutting oil on the blade either.

Careless sprinkling of hot swarf on colourbond painted surfaces means speckles of rust appear in just days. This coastal installation shows why roofing contractors can rightly demand sheets be replaced on new buildings; cleaning up once you’ve made the hole is essential.

The aggressive environment explains why using a flashing without screws makes sense. If only it had been blown/swept/wiped up properly, the roof would not be rusty.

This conduit was already sealed, so the flashing is a bit decorative but still badly fitted.

Stainless screws and smudges of silicone are ok, but gaps that trap moisture and rusty swarf etching into a spanking new roof aren’t

Fast forward a few years, where failing to finish/feather the edges of the silicone means it doesn’t adhere properly, then water seeps underneath.

Moisture has crept under the edge.

Some People Don’t Deserve Roofs

Flashings should allow water to pass, but having lined them up across the pan, this numpty’s created a dam to hold water.

Blue shading shows side-by-side penetrations create a pool on the roof.

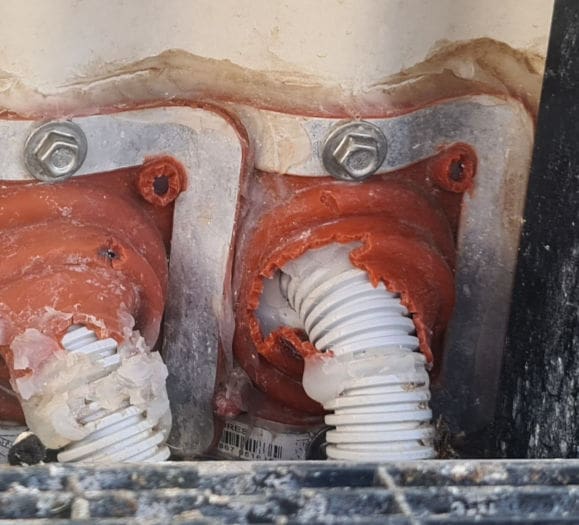

Of course, things could be worse; overlapping flashings that birds subsequently ate are another liability.

Galahs and Corellas chewed everything off this job.

Other Obstacles Can Force Your Hand

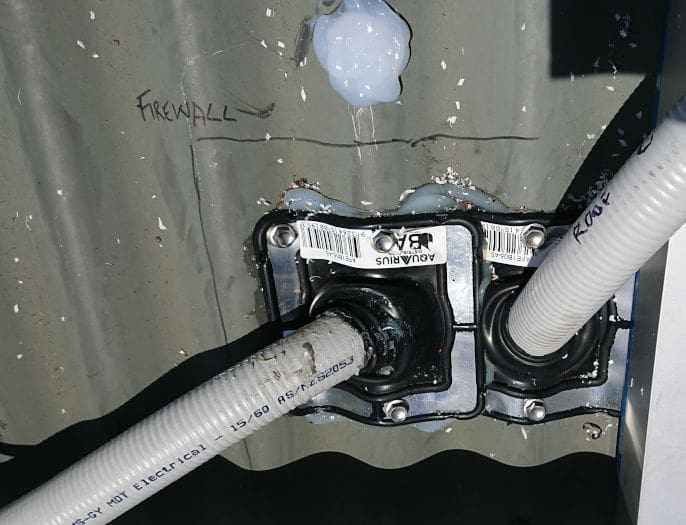

This image shows whacking a holesaw through where a pilot hole would do can lead to unitended damage. Nursing homes full of firewalls mean you don’t always have a choice, but I always try to measure or dent the surface to check from the opposite side, before piercing the roof.

A hole punched through the wrong side of a firewall is bogged up, and more holes end up too close together.

Roofers Can Have A Different Approach

When this house had new cladding installed, the roof plumber made holes and pulled the existing solar wiring conduits through to seal them himself. Years ago, I used this method without issue. In reality, this won’t leak, but it doesn’t meet solar standards, so we put a flashing over it anyway.

Two existing conduits sealed with urethane by a qualified trade during re-roofing

Shedding Water Should Be Second Nature

While it’s less likely on steeper pitches, these shaded areas show how water is often held up behind flashings. It’s a needless opportunity to start corrosion, mould and leaks.

Plenty of silicone used, which exacerbates water pooling on lower pitched roofs

Blue shading to highlight where water pools & dirt collects. Badly placed screws but at least it’s all sealed with silicone. Bonus crap electrical practice with unglued couplings too.

Even Plumbers Make Mistakes

This “stink pipe” has been nicely flashed with pop rivets to secure the dektite. Four holes in the bottom of the channel will hold the rubber down nice and tight, but it’s still the wrong method.

Water leaks through rivets easily if they’re tubular ones. Best practice is to use blind rivets and cover them with silicone to prevent corrosion attacking them anyway.

40mm plumbing vent with mud showing exactly where the water pools and then runs across the flashing

Finding Leaks Is A Challenge

Unprotected from the western sun, this badly executed shit show of overlapped flashings was the suspected source for a water leak. To diagnose it, we troweled a whole tube of silicone in, simply to displace any water that might sit on top.

Ultimately, warranty obligations saw the entire 100kW array removed, reframed and reinstalled, so the wiring got a once over and this rubbish was repaired with a metal patch.

Eventually the scab was ripped off to make proper repairs.

Don’t Despair: Most Roof Penetrations Are Fine

It took years to gather all these examples. Even the terrible mess shown above didn’t leak water when we examined the entrails.

If your roof looks depressingly similar, then tune in next week. I’ll show you the best tips and tricks to make durable watertight penetrations in the roof.

There will be contrasting pictures and step-by-step guides you can show the people working on your house as an example of best practice.

It’s almost as exciting as writing about conduit!

RSS - Posts

RSS - Posts

Key takeaway from this.

Years ago, I used this method without issue. In reality, this won’t leak, but it doesn’t meet solar standards, so we put a flashing over it anyway.

And create a problem that didn’t exist before.

Hi Jon,

This is sometimes what standards do, like the mandate for Rooof Top Isolators that we eventually got written out of the rules.

While I’ve always sealed conduits, the flashing becomes mechanical protection for the sealant, meaning it doesn’t degrade in the sun if the penetration isn’t under the panels.

Loved that article. Although it is devastating to see what’s often being produced by trades people.

Not just talking about solar, this also applies to gutters, valleys, roof hot water systems, whirley birds, antennas, skylights, shade sail anchors , and pretty much anything that penetrates a roof.

Don’t forget the rails for the solar panels. BTW my roof is concrete tiles, all your examples are for tin roofs, but I assume tiles can be as bad

Hi Dirk,

Glad you find it useful.

The next instalment is coming and we’ll have a tile penetration article out soon as well.

Thanks Anthony. Scary stuff and leaky rooves are a pain. It’s also not something that the home owner can easily inspect. A conversation with the installer prior to the job starting sounds like the way to go. I’m curious to know why the cable can’t be taken up to and under the ridge capping or brought down to bottome of the roof sheet and into the roof space above the gutter? Looking forward to your next article on how to get it right.

Thank you again for the interesting articles.

Hi Andrew,

Glad you find it interesting.

AS 3000 means you can’t have cables under a finished surface where screws might be put through them… so there’s no ifs or buts, wiring SHALL go through the roof at right angles.

Thank you for your quick reply, Anthony. Thank you for being there for all of us home owners who are novices when it comes to the important technical issues.