2 x 5kW SMA Sunny Boy Inverters. One made in China (SMA SB 5.0-1AV-40), one made in Germany (SB5000TL-21). How do they compare?

SMA have released a new single phase inverter. They kept the same joyful name of “Sunny Boy” however the model has changed from what was known as the “dash 21” to the “dash 40”.

But let me tell you a well-known secret about the SMA “dash 40”. The respected German manufacturer is manufacturing these new SMA inverters in China.

Bombshell.

Has this turned the single phase model of SMA inverters into a cheap Chinese inverter? To find out, I bought myself a 5kW Chinese-built SMA “dash 40” and pulled it apart to compare it to the 5kW German made “dash 21”.

In this post, I’ll first look at the external features: the “smart screen”, the Sunny Home Manager, and the inbuilt DC isolator.

Then I’ll look at the internal build quality, and where the different components are manufactured. Finally, we’ll discuss the after sales service and warranty of SMA.

While writing this blog I had lengthy discussions with Scott Partlin from SMA. Scott is well respected in the solar industry. He was very candid and helped me understand the direction SMA are heading and the reasoning behind what SMA have done with the new Chinese Sunny Boy that, as they fairly put it, is “assembled in China”.

Part 1: The Externals

Where is the Sunny Boy screen?

The first thing that screams out when you look at the SMA is there is no screen. The display screen, I am told, was the most common failure point in the SMA, so the clever German engineers got rid of it.

“Kein Problem! ”

The idea of leaving the screen off is not new. My friends at Sungrow pioneered the stupid idea with their new Crystal series. But thankfully Sungrow (because they are Sungrow) listened to the installer outrage and gave us an optional plugin screen.

Rather than marketing “no-screen” SMA have used the euphemism “Smart Screen”. Instead of a screen, we now have the ability to connect the inverter to a smartphone, and the inverter has three simple indicator lights to indicate the inverter’s status.

Introducing the SMA smart screen. It’s on your smartphone. Geddit?

In my business, it is common to get calls from random homeowners who wouldn’t know the difference between an inverter and an instant gas hot water system. They want to know if the solar panels on their new home are working. In fairness, the majority of the time, if the “green light” is on, the solar is working reasonably (assuming they are in fact looking at the inverter). But I always spend a bit more time and ask the homeowner to give me a few readings from the inverter screen. I crunch some numbers to get a clearer picture of the systems’ performance.

Occasionally although the “green light” is on, there are system performance issues, so we arrange an onsite service. This type of “unplugged” diagnosis will be no longer available with the new SMA. The homeowner will have to be technical enough to work out how to connect their mobile phone to that Smart Screen inverter thingo – not to mention remembering the password!

I have no doubt that removing screens will increase the occurrence of some solar systems being left underperforming and undiagnosed. That’s not good for anyone.

On the other hand, there is no doubt “..a fault has come to light with the Comms interface where it seems to be unreachable and hence the inverter can’t commission/operate.”

All I want to know is: why do people use the word “hence” when the word “so” would have done just fine? Anyway, what’s so good about the Smart Screen?

Smart Screen vs. dumb screen

SMA obviously carefully considered going screen-less. Here are their reasons:

- Removing the inverter’s display screen will reduce manufacturing costs and reduce warranty issues.

- The “smart screen” will allow for much more information (historical data etc.) than the dumb screen.

- The smart screen can be updated automatically by SMA. In a rapidly developing industry, that’s nice!

- The smart screen will make way for what Scott called a “digital compliance paper”. In short, this is the world where an inverter becomes more about software than hardware. You make and ship a million identical inverters. If the customer wants a 2kW inverter, the installer unlocks a 2kW inverter. If they want a 5kW inverter, pay a bit more and unlock a 5. The inverters are all the same, but you pay for access rather than for hardware. In case you think SMA are dreaming, ABB and Huawei are planning the same.

Smart Screen and dumb screen?

Unfortunately, it seems that the industry is moving towards removing inverter screens to reduce production costs and warranty issues. ABB are considering dropping the screen in their next model. Thankfully SolarEdge’s brand new HD Wave currently has a screen, but they too are in early talks about dropping the screen in their next generation. My take? Until the concept of a “Smart Screen” is proven reliable and widely adopted by consumers we need an option of a basic plug-in screen similar to Sungrow’s. Plug-in screens will be more reliable as the exposure to the internal heat of the inverter will be removed.

Hey, solar inverter manufacturers – be like Sungrow.

SMA Energy Meter

Energy consumption monitoring was always possible with the old Sunny Boy. The problem was it was expensive and complicated. The new Sunny Boy SMA Energy Meter is now like the Fronius Smart meter. It simplifies the process with a kWh meter that connects directly to the inverter. Both the SMA and Fronius meters monitor:

- how much grid electricity you use

- how much solar you use

- how much solar you feed to the grid.

They then graph this data on an online platform (SMA’s can also be accessed directly on the device without Internet). Both also allow zero export to the grid to be directly configured on the inverter.

Consumption monitoring has enormous benefits as I have previously explained. The difference between the Fronius and SMA’s monitoring is what the inverter can automate with that information, which brings me to SMA’s Sunny Home Manager.

Sunny Home Manager 2

The Sunny Home Manager 2.0 (SHM2) is an upgrade to the SMA energy meter. Not only does it monitor your power, but it can also and help you make the most of your solar energy. It will be available in June 2017. It combines all of the features of SMA’s old Home Manager and the Energy Meter into one device. The product includes weather forecasting to estimate the amount of spare solar energy 48 hours in advance. The Home Manager can then directly control “smart” devices through an Internet-connected cloud system to divert solar energy for consumption on site.

SMA’s choice to make load control funkier seems more complicated. The SHM2 can communicate via radio signals or EEBUS to fancy third party plugs that can connect to your washing machine or dishwasher. Alternatively, you can connect directly to a compatible appliance like a heat pump. Without being too dismissive, this level of home automation isn’t yet where it needs to be, especially because compatible appliances are not yet on the shelf in Australia, never mind in the customers’ home.

More importantly, SMA missed the low‐hanging fruit. The new Sunny Boy didn’t allow for a programmable “dry contact” to cost effectively control hot water with a simple relay. The Fronius solution simply uses the standard Fronius smart meter to automatically switch on your hot water tank on when excess solar power is available1. This method won’t heat 100 percent of your hot water with solar, but when correctly designed, it’s a cost‐effective and durable method of getting most of the way there.

I should explain I work in Brisbane’s market, and my bias towards simple hot water load control has a lot to do with Brisbane electricity tariffs and other local variables. Some of my customers – and many others around Australia – will see more value in more expensive hot water diversion. I explained the concept of hot water diversion in this post. Since I wrote that post, Fronius, SolarEdge, and CatchPower have all entered the market with similar devices.

Inbuilt DC isolator

The new SMA Sunny Boy comes with an inbuilt DC isolator. The advantages of having an Australian Standards compliant inbuilt DC isolator are:

- The installation looks neater without extra cables, conduits and enclosures,

- It ensures a high-quality DC isolator designed specifically for the inverters load, and

- It ensures that the IP rating1 of the isolator is not dependent on the installer’s workmanship.

The problem with SMA’s inbuilt isolator: it’s not yet compliant.

According to the relevant Australian Standards, to comply installers must provide one of the following:

- (a) An adjacent and physically separate switch-disconnector.

- (b) A switch-disconnector that is mechanically interlocked with a replaceable module of the PCE, and allows the module to be removed from the section containing the switch-disconnector without risk of electrical hazards.

(AS 5033 clause 4.4.1.2)

English Translation: to be compliant, the DC isolator must be capable of remaining behind on the wall if the inverter needs to be replaced under warranty. So if we install a Sunny Boy inverter, we also have to install a separate third party DC isolator adjacent to the inverter.

There is a push by SMA and others in the industry to have this clause amended, and rumour suggests this may happen in the next 12 months. The standards update would make Sunny Boy’s DC isolator compliant. However, while SMA has the support of the Clean Energy Council on this proposed amendment, CEC tech support advised me:

“Don’t hold your breath.”

Fronius had been the only inverter that has a compliant inbuild DC isolator, but the SolarEdge HD wave has just matched it. With Fronius and SolarEdge, this allows for a cheaper, simpler, neater installation and requires no additional third party isolator for warranty purposes.

Part 2: The Internals

The electronics

The question remains as to whether moving to China will impact the quality of SMA inverters. Let’s have a look under the hood.

German SMA internal

The old German SMA has one large printed circuit board. Everything about it looks immaculate – as you would expect from SMA.

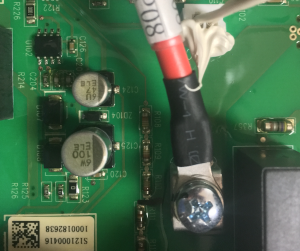

Chinese SMA internal

The Chinese SMA is made up of four separate boards:

- The Control board is still made in Germany and is shipped to the Chinese production line. This is the board that sets the limitations of the inverter, the grid codes, and interfaces with the grid.

- The communication board is also still made in Germany. The name says it all. It’s responsible for WiFi and EEbus connectivity.

There is irony here: the part of the inverter that has been failing in the Chinese SMA was the Communication board – the part that was made in Germany!

- The power board is made in China, not at the Chinese SMA factory, but at another third party PCB manufacturer. This is where the DC to AC conversion happens. It’s what replaced the transformer in old inverters to make inverters transformerless. The board uses H5 Bridge (a technology that SMA introduced into the market) which switches five transistors (in the form of an “H”) to chop up the DC into a 230v AC output.

- The AC filtering board is also made in China. This board cleans up the AC wave that comes out of the Powerboard for compliance.

Zoom in

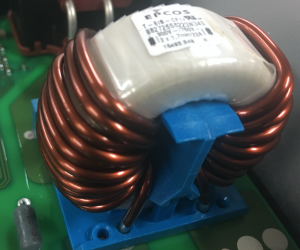

At closer inspection, the boards that were made in Germany looked neat. The boards that were outsourced to a Chinese PCB manufacturer were visually lacking. Take the build of the Chinese inductor on the AC filtering board for example. The inductor is made with a rough cut aluminium separator, sloppily wound tape make up the insulation between coils, and a blob of black goo to hold it all together. The German made inductor looks like… Well, it looks like it was made in Germany.

German SMA inductor

Chinese SMA inductor

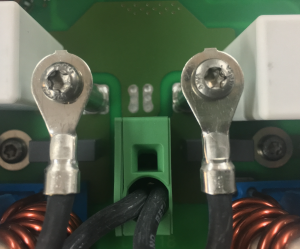

Stainless Vs. Zinc

Another example is the various fasteners inside the inverter. The German stainless steel torque fasteners are designed for overkill with machine torqued tightness and stainless longevity. The Chinese Phillips head zinc plated fasteners were designed to save money. Add a healthy blob of silicone on that plug for good measure. Maybe I’m nit-picking – but no more than they were in the German factory. The aim of the SMA-40 was always to cut costs and stay competitive in a competitive market. Cutting costs has resulted in a compromise of craftsmanship. Time will tell if that translates into reduced reliability.

German torque stainless bolts

Chinese Phillips zinc bolts

Fewer Capacitors

Capacitors (found on the power board) are a key component to string inverters. Decreasing the number of capacitors will decrease the cost of the inverter. The new SMA has cut costs by installing only eight capacitors. Compare this to the previous SMA which has 10, and the Fronius which has 12. A key reason you need more capacitors is to increase the inverter’s DC voltage limit. The new SMA can have a Maximum of 600 volts; the old SMA could take 750 volts, where the Fronius can cop a massive 1000 volts DC.

So a higher voltage is better right? Well, not in a domestic situation where we can only have a maximum of 600 volts DC anyway. As it turns out, less is more! For best efficiency, we want to match the inverter’s nominal DC voltage closely to the voltage from the panels on the roof. This tends to be below 500v in a home.

This is one place where the SMA trumps the Fronius. (However, Fronius are coming with a new model in 2018, and a little birdie told me they would fix that capacitor/high nominal voltage issue.)

No Fan

SMA heatsink (removed from the back of the inverter case)

The new Chinese SMA is fanless. It uses a large heatsink to keep the inverter cool.

The upside to not having a fan is less moving parts to fail and less noise.

The downside is the ability to move heat away from the electronics.

The previous, almost indestructible German Sunny Boy was also fanless, so I’ll resist suggesting an internal fan would be better.

Part 3: Support and Warranty

SMA support

SMA technical support over the last 12 months has been, at times, pathetic and they openly admit it. When I asked Scott why, he explained that Germany enforced a “head count freeze” last year, so SMA Australia was understaffed. They also had notorious phone systems issues.

But with the introduction of the new Sunnyboy, SMA Australia are well and truly back on the horse. An installer recently told me that although he had 2 SMA-40’s “dead on arrival” he couldn’t fault SMA’s after sales service in this instance. That’s a promising sign, at least for their support team.

Warranty

Their new SMA warranty procedure also sounds promising. If an SMA inverter is connected to the internet and registered with SMA, then SMA will be notified automatically of any inverter errors. SMA will then proactively arrange an inverter replacement with the installer with a guaranteed five-day delivery. (This is a far cry from the painful procedure we had to go through with the very occasional SMA-21 inverter we had to claim under warranty.) Even better, because the cost of manufacturing SMA inverters has dropped so low, all inverters that fail within the warranty period will be replaced with a new inverter rather than be repaired.

SMA currently offer a 5-year standard warranty. It’s $325 to add a basic 10-year warranty. SMA are considering making a 10-year warranty standard. Let’s consider the following premises:

- SMA are up against a SolarEdge 12-year warranty and a Fronius 5+5 year warranty.

- SMA has always been a reliable inverter, with a failure rate of less than 1 percent.

- The screen was the weak point in the SMA-21, and they removed it in the new Chinese model.

- Building the inverter in China will not reduce reliability.

The conclusion: The decision to offer a 10-year warranty would be a no-brainer. Unless, of course, premise 4 is incorrect.

For me, this is the clincher. Will the build of the SMA-40 be as reliable as the good-ol’ German SMA-21? SMA would know the answer to that question best. Let’s see if they put their money where their mouth is, and offer a 10-year standard warranty.

Conclusion

The new Chinese SMA Sunny Boy inverter has unashamedly cut costs. They dropped the screen on the front of the inverter, and it seems the industry is just going to have to get used to that.

The SMA energy meter is a welcome addition: load monitoring should really come standard with solar systems today. However, the load control that SMA offer with their Sunny Home Manager 2, is a little too advanced to be of much use today.

The DC isolator is not yet compliant, but if the relevant standards are amended, it will make for a neater, safer and more cost-effective install.

The printed circuit boards made by a third party in China look a little sloppy, but ironically it was one of the German made PCB’s that failed in the rollout of the new Sunnyboy.

While the after sales support is looking promising, the SMA warranty period needs to be extended. It will be interesting to see if SMA back their Chinese made product with a 10-year standard warranty.

Footnotes

- IP rating determines whether water will get in to an enclosure and go bang!, as up to 600V DC short circuits ↩

RSS - Posts

RSS - Posts

Thanks for the interesting article Mark.

I recently had a solar system installed and it came with the new SMA inverter with no display. I can understand for a layperson the display is probably easier to access information especially if the owner is non tech-savvy.

There are a number of ways to get the information out of these boxes and you don’t have to use a smart phone. My install I had an Ethernet cable installed and connected it back into my router as I prefer using Ethernet around the house where my devices have Ethernet sockets. The Inverter should by default be using DHCP and be assigned a LAN IP address by the router. Normally the router will just assign the first free unused LAN IP address. I use the Inverter’s Ethernet MAC address and tie it to a specific IP setting in the router so I know exactly what IP address it has. They are still served as DHCP connections as far as the Inverter is concerned.

To access the SMA box I just use (for example): http://192.168.1.x in a web browser on a PC.

The above should also be possible by having WiFi connect to the router but requires the SSID and WiFi password to be configured in the Inverter. That’s probably going to create headaches for the installer though if the owner changes their WiFi log-in credentials!

Thirdly just use the built in WiFi acting as an Access point. It’s basically a WiFi DHCP router like an ordinary router has. I believe this is what the installers use to configure the boxes. The log-in details are on the back of the supplied manual on a sticker.

I don’t like leaving the WiFi Access point switched on as it is a security issue (broadcasts the SSID) so I disable that side of it and only enable it if needed by the Installers so they can access the Inverter while on site.

Lastly it should be possible to configure the router to open up a port in the router to the Inverter so that the Installers can configure it from any place in the world. You need to make sure the passwords are secure though (don’t use default ones). Problem with this is that it can be a pain to configure in the router especially for a non tech-savvy owner but might be worth doing if installer is not located close by and needs to fine tune the Inverter frequently.

I don’t think the low level settings in the box can be configured via the SMA SUNNY PORTEL site? If that was possible it would make life easier for Installers.

Just a quick note on the Chinese Inductors. The yellow tape looks like standard Mylar Inductor tape designed for the purpose. Where I once worked we used to custom order 100s of these from Chinese manufacturers for use in Inverters. Very cost effective and reliable. They used the same sort of core re-enforcement. There are probably 1000s of small businesses that produce these in China and they are very competitive.

I removed the booster capability on my heat pump when I installed it and also fitted a time switch so that it only comes on at midday when air temperature is most efficient and solar panels are most productive ( on average) so it’ sefficiency is maximised- thus not needing smart technology to optimise.

I hardly ever used the display as the inverter is in a corner of my garage.

I just find the Oxley Solar display app on my phone more useful .

Add the SMA ethernet connection back to base and what more do I need?

I would have liked a monitor because I have to use 2 monitors one from Owl and the other from Engage as I have 3 phase power and I just have not got enough connectors to monitor my power at any given moment accurately.

The AGL app gives me a daily consumption but its two days out of date and I am not actually sure what it is measureing , I assume it measures total consumption and then some how works out the cost per meter .

Hi, Eric, an ethernet connection is definitely the most stable. I hadn’t heard of the Oxley solar app. I just looked it up – looks good! Sounds like you are all over it! I’ve just moved into a new home and we are going with AGL, partly because I want to check out and review their monitoring platform 😉

Very informative article!

The core-insulating tape on the Chinese inductors looks OK, but why on earth use an aluminium winding separator? Such a common-mode choke has line voltage between the two windings (hence the insulating tape) and any physical separator should very definitely be non-conducting. The enamel on the wire is sufficient for inter-turn insulation, but nothing more. And the oxide layer on the aluminium offers no useful insulation at all. Much better would be a bead of non-melting goop in each inter-winding gap, and NO aluminium.

Yes, there is a physical barrier across the diameter of some of the 240v common-mode chokes I have within arm’s reach _but_ they are made of plastic. They fit into slots in the plastic insulating jacket moulded onto the toroidal core, so they can be installed after coil winding.

I’d be curious to hear which test house performed compliance testing on the dash-40, as it should not have passed with that metal short-circuit risk, in my opinion. All it takes is for either end of both windings to contact the metal, then electrical breakdown would be immediate, I suggest.

I’d definitely make sure my fire insurance was fully paid up before installing anything with a chunk of aluminium which could short out the input or output power bus.

Substitution of large heatsink fins for a fan sounds very good, though. After the display, the fan would be the first thing to give up, as in other equipment.

Get rid of the aluminium on the choke, and I’d consider one.

If you are referring to the main Choke in the inverter, those are absolutely Copper, and encased in the back of the inverter (and with potting mixture) and not accessible. This component by itself makes up over 1/3 of the inverters total mass.

The smaller filters shown are just for final EMI filtering of harmonics on the AC out board.

Thank you Scott, for your attention to this critical safety issue.

No, I did not refer to the main inductor. (Which I am pleased to hear is suitably beefy, and copper wound. It is not visible in the article’s photos, so I had offered no comment on it.) It is the smaller filters which pose the safety risk, as illustrated, not due to their purpose, but due to the degradation in the Chinese design.

If you could please take a glance at the text surrounding the two photos comparing German and Chinese common mode (EMI) chokes on the input and outputs of the inverters, you will read “The inductor is made with a rough cut aluminium separator”, and see that the German unit has, in contrast, a much safer _insulating_ plastic separator.

If a technically literate person reads my prior post, these word will stand out: “The core-insulating tape on the Chinese inductors looks OK, but why on earth use an aluminium winding separator? Such a common-mode choke has line voltage between the two windings (hence the insulating tape) and any physical separator should very definitely be non-conducting. The enamel on the wire is sufficient for inter-turn insulation, but nothing more. And the oxide layer on the aluminium offers no useful insulation at all. Much better would be a bead of non-melting goop in each inter-winding gap, and NO aluminium.

…

I’d be curious to hear which test house performed compliance testing on the dash-40, as it should not have passed with that metal short-circuit risk, in my opinion. All it takes is for either end of both windings to contact the metal, then electrical breakdown would be immediate, I suggest.

I’d definitely make sure my fire insurance was fully paid up before installing anything with a chunk of aluminium which could short out the input or output power bus.”

A small piece of aluminium does _not_ serve as an insulator between conductors with 240 Vac (380 Vp) potential difference on the output, and perhaps 600 Vdc on the input. It serves only to _reduce_ safety, by reducing the insulation gap between windings. Can you please refer my well based concerns about the electrical breakdown and potential fire hazard posed by substitution of an insulating inter-winding barrier with a hazardous short-cicuiting bar, to a qualified and experienced electrical engineer, from the German R&D department, if it still exists. (Forgive the specificity, but after having spent 30 years leading R&D teams at transnational telecommunications equipment manufacturers, I tend to have greater faith in contemporaries. And having worked at Siemens’ Hofmannsstrasse R&D complex, I have come to respect at least the laboratory leaders as highly competent. And if a reply in German is more convenient, that will serve equally well.)

It is much simpler to fix it now, than to endure a later high volume product recall.

Great article Mark. Thank you very much.

In the TL20000 EE, SMA has left out the screen as well. In my experience the screen is quite vulnerable, especially if the inverter is mounted outdoors.

The fan is indeed usually one of the most common failure points as well. As long as the passive cooling capacity is sufficient, I think it is a good move to leave the fan out. Fans usually need to be cleaned and checked on a regular basis. These 5KW inverters are obviously used in the residential systems, which are know particularly know for their intensive O&M cycle. A truck roll is relatively expensive if you look at the number of kWh’s that you gain in a residential system.

Eelco, regarding your comment on residential, O&M, etc, I’m not sure that Mark’s article clearly articulated one of the other big differences between the new and old Sunny Boys (but as he had a lot to write about, that’s understandable). The new Sunny Boy has introduced a free proactive service model to help reduce downtime and the “lost kWh’s” you alluded to.

(https://www.youtube.com/watch?v=VE_VDDPV8lU)

From Facebook: Zeversolar 5kW vs. SMA 5kW

Finn, are those really aluminium separators across the common mode line chokes? If they are, have you asked whether the design has been subjected to compliance testing? Plastic would be fine, but a gooped-in-place conductor only has to become loose enough to touch both coils, and you have a line short. Not only does electronic equipment stop working once the magic smoke is let out, but at 5 kw there’ll be more than just smoke.

When returning a busted Chinese compressor, the response has been “Put it against the wall with the others, and take a new one.” If that’s to be the approach with their inverters,I’d hate to have just inverter s/c detection between me and a house fire. We need to demand adequate construction.

Compliance testing is done according to IEC62109-1 (https://webstore.iec.ch/publication/6470) and IEC62109-2 (https://webstore.iec.ch/publication/6471).

Regarding those standards, ALL critical components need to be below specified temperatures limits as defined in the standard.

Further to this, any critical component must be listed in part 14 of the standard and cannot changed without the inverters undergoing re-certification testing.

Within Australia, the approved listing condusts random checks of inverters to see that none of these critical components have been “switched” out as has previously been done by “lower quality” manufacturers and suppliers.

Scott, thank you for responding. Your studious blindness to the electrical breakdown hazard posed by misguided placement of conducting metal in lieu of an insulating interwinding barrier, where voltages of 240 Vac or 600 Vdc, at high power levels may exist, risks continuation of the hazardous practice.

Please send a link to this web page to suitably qualified engineers in Germany, and ask them to sign off on the Chinese practice shown in the photos.

Also, let us take a Chinese inverter with end turns already close to the aluminium, slide the turns into contact, and then:

a) First try to operate it normally at full input voltage, then

b) Perform an insulation test, according to the applicable standard

(And no extra lacquer to be applied to the coil end prior. 😉

Given I have intimate knowledge of both products, their pre-design and their manufacture, I can offer some additional perspective which these photo’s are not able to reveal:

Individual components in and of themselves do not immediately translate to a reliable product. The reliability of a product is dependant upon how many things. How components are chosen together, how they are all screened and checked, what pre-production performance and durability testing is completed, what in-production quality systems actually do and other things like this which ultimately delivers a product’s performance and overall quality.

It will not be apparent to the untrained eye, nor observable from these photo’s, but there are significant differences in some key components in each brand of inverter, and very significant differences in the control and operation philosophy and firmware that make the 2 inverters very different.

If one were to look closely at, for example, Lexus and Toyota, or Audi and Volkswagen, they would find many similarities, but the final product is very different.

Scott, the methods for computing reliability of complex electrical equipment, made up of large numbers of components, each of known reliability (in FIT), is well established, and I have (admittedly some time ago) performed such calculations.

Consciously comforting circumlocutions aside, the input and output line filters in an inverter are SPoFs (Single Point of Failure), as shortcircuiting of either input or output at high power levels tends to be destructively pyrotechnic.

The time for issue-avoidance is over. The matter now needs to be referred to competent development engineers in Germany. (With all due respect, I have dealt with sales engineers before, and have myself had to deal with what they have told customers.) Let’s clean up this latent hazard now.

“I was at home working on my Sunny Boy inverter, so I couldn’t be at work to take your call”

The word “so” has two subtly different meanings, depending on the context – was the speaker above explaining his absence, or confessing to having concocted a way to avoid speaking to the listener?

“I was at home working on my Sunny Boy inverter, hence I couldn’t be at work to take your call”

Much clearer – turns out he wasn’t being a jerk to the listener after all.

You asked.

Thanks Conan the Grammarian. It is always nice to find other people out there in this wide world, with an appreciation for the correct use of the English language.

Though not a monarchist myself, I am sure her Majesty will appreciate your support of her language.

In the original quote the comma after the word inverter implies two separate thoughts, hence the first explanation is the only actual meaning, but we digress…..

I just got the SMA Sunnyboy 5.0-1av40 fitted at my house but the wifi connection wasnt set up perfectly i guess. I can see the solar energy produced by the device but the box that shows the energy consumption has no reading, Neither does the energy feed-in management section. (this is when i log in through the i.p address link). On the sunnyportal these options aren’t there at all so i’m quite unsure if the SunnyBoy 5.0 is even capable of telling me the energy consumption of my house or if its just a case where the install was not perfect.

Any advice would be helpful. Thank you.

I have the same Sunnyboy model. For those extra readings (i.e: local IP and the Portal site) you would need to have extra optional devices connected into the system to measure those as the Inverter can’t tell. Without, all you will see is the Yield values.

For completeness, SMA have offered their own take on the topic with a blog post here:

http://en.sma-sunny.com/en/a-change-for-the-better-from-old-to-new-sunny-boy/

the 4.0 has a larger fin area than the tl4000-21. this also reads back in the higher temperature tolerance of the 4.0 depicted in the derating curves.

I have my panels connected such that it operates near 330V, so the MPPT section has minimal work. I worry most about all the large electrolytics caps. An ESR test feature would b e nice to have such that a replacement indicator can be triggered. ripple current ratings are ideal to program controlled failure, to get just past the guarantee period.

I have the Chinese 5 kW model. I’ve been happy with it’s performance on the electrical side but ever since day one it has a date problem in the box itself and SMA can’t offer a solution on how to correct it. I don’t even think they understand the problem and their only solution is to fit another unit. I don’t think there is anything wrong with the unit itself and it just needs to be RESET to correct the date issue. I’d rather the problem is corrected in this unit rather than being provided with an exchange unit that my not be new and possibly older than my unit.

So in the hope that someone here might know how to correct the date issue I will document what has happened…

The unit was installed on the 19th April and was operational at 2:30 PM and producing power. The unit was not able to connect to the Internet that day because of some unknown issue (I ended up having to reset my modem and router). The next day I let my Installer know it was now able to access the Internet. The installer commissioned it with the SMA Portal site at 9:30 AM the next day.

The problem is when I look at the Yield before 9:30 AM local time it is showing the yield from the day before ADDED to the current day’s Yield! but as soon as the time reaches 9:30 AM it shows yesterdays and today’s yield correctly. Now when the time reaches 2:30 PM the date under the “Day” tab shows the next day’s date!

It’s obviously has something to do with the Commissioning time (9:30 AM) and first activation where it was starting to generate power (2:30 PM on the install date)

They have tried Firmware updates (which I knew would not solve the problem). The box time is correct and is set to the correct time zone.

I’m using an Ethernet connection (or WiFi access point method) to the box directly to see the built in web server pages.

Here is the older model (Blue-tooth) that talks about the same? issue so SMA are aware of this sort of problem:

http://en.sma-sunny.com/en/service-tip-1-setting-the-system-time/

The question is how to correct this date issue? I’m an embedded systems engineer and this is hardly an issue that I would expect requires that the box to be replaced and is absurd to have to do that just to fix a date issue.

Does anyone know how to fix this date issue?

I have now been informed it is UTC bug (high up in SMA) in the software and waiting for a firmware update (I will be testing the beta firmware). This is after 2 replacement inverters, head banging and lots of contacts since my first post. See how that goes but there are still other major issues with these inverters I see, each one has had major issues apart from this.

I bought a cheap and cheerful component tester from Banggood (a cheap and cheerful Chinese goodies vendor). It’s no precision meter, but will tell you whether a capacitor has 0.05 ohms or 0.5 ohms of ESR. It was a kit, so a bit of soldering required. (I figure you’re savvy enough to discharge the caps first.)

Testing inverter capacitors, which may have 600v DC on them for quite a while after array disconnection, however, is a quick way to kill yourself, so only for the fully qualified, and even then, can be avoided.

A direct ESR measurement is in any event of dubious usefulness, as all the caps are in parallel, so one good one will mask a bunch of crook ones.

Even for the qualified, a quicker and safer capacitor check is to aim a non-contact thermometer at them from a suitable spot ratio range, I think.

As removing the cover is not for housholders, measuring the immediately adjacent enclosure wall from the outside is the way to go. (on living)

Measuring annually, after e.g. running a 2 kW bar radiator for a fixed time, long enough for the heat to radiate to the wall, should allow a temperature

analogue of ESR to be obtained.

Looking for bulging of the top of any of the caps unfortunately involves removing the cover, and is a last warning, in any event.

I expect the caps to deteriorate all the same. the hardware should be able to measure the ripple voltage and derive some statistics from that. I have a 1mm spot IR thermometer that has helped on many occasions.

I expect a lot more SW updates on the chinese version. first of all the parameter description as published on the web does not match the parameter names in the device. then there is a discussion on the grid guard code, if needed in the offgrid mode. one support engineer says yes I need it, the other says no, and the proof of the pudding: I can freely change parameters after the 10 hour incubation time. sofar there is no documentation on the parameter names and explanation. guess they did not have yet time to translate it from chinese.

I blocked the internet access by the SB4.0 and found it tries to connect (every 15sec) to ip 171.25.178.74:9523 assigned to sma.de. it uses an UDP protocol from port 56306 in the SB. just wait and see when someone manages to take over all SB’s new style..

If you set a firewall rule which allows connections on those ports only when initiated from your side of the firewall, and only to the sma.de IP, then no connection on those ports can be initiated from outside, and not to any other destination. I.e. the SB should be well armoured.

I don’t know what the Microsoft OS uses for a firewall, but a Linux box allows a variety of tools for setting the firewall rules, with varying degrees of ease. It is the kernel which then does the work of packet dropping. (Optionally silently, to hang the attacker up, futilely hoping to get through.)

But if the SB continues to function without calling home, then I’d isolate it too.

I certainly do not intend to have my inverter network connected, beyond a weekly health report, if that’s a warranty requirement.

Surely the OP is using a router of some description? which would naturally block all incoming connection attempts by default. I would also make sure it is in Stealth mode to stop ping requests and port scans. Any Internet client side software is likely to try and call out if you allow it and possibly for innocent reasons.

>> I certainly do not intend to have my inverter network connected, beyond a >> weekly health report, if that’s a warranty requirement.

This is the message that SMA Portel will send you if your unit is registered on the portal and it can not talk to the SMA box when it tries to connect out. This may happen because of a power or Internet outage. I’ve received these messages when disruptions that have been under 24 hours…

The email message:

“We have identified a communication error in the PV system OWNERS NAMES, which affects the following device: SB5.0-1AV-40-IED (serial number: xxxxxxxxxx).

The usual cause of such a disturbance is a faulty Internet connection.

As a result of this disturbance, Sunny Portal cannot receive data correctly, meaning that the proactive inverter monitoring function provided as part of the SMA Smart Connected service is not assured.

In order that SMA can continue to provide the promised service, we kindly request that you remedy this error.”

the main reason would be the tax that the spanish government places on produced electricity, wether consumed or PV generated. as island systems do not deliver any metering, intercepting inverter monitoring would be a means of metering.

Is there a price difference between the old and the new inverter? I’ve recently had a -40 installed but my quote (and invoice) is for a -21.

Inverter prices have consistently fallen over time, although currency fluctuations and shortages can, temporarily, reverse that. So a new model inverters will often have a lower price than the previous model. But older stock can then be discounted so it will shift. The new Sunny Boy came with a price decrease.

The larger an inverter’s capacity, the more it will cost, all else equal.

For a household what is important is quality of the components and the total cost of the installation rather than values given to individual components of the quote, so it may not be worth worrying too much about one component.

One thing I will mention is, if the inverter that is installed differs from what is on the application to install rooftop solar made to your Distributed Network Service Provider (DNSP), then they can have an issue with that. But hopefully you won’t have a problem.

there is a max PV voltage difference between the 4.0 and 4000-TL21.

the 4.0 can handle up to 600V while, the -21 can handle up to 750V. it’s easier to place some extra PV capacity when using the -21.

finally I got the conformation on gridguard from SMA. If you initially select offgrid mode (in the first 10 hours of operation), the device does not need any gridguard code to have its grid parameters changed.

stewart,

my inverter has also gone into the date error, I reported it to SMA spain as a bug, never heard anything back since. My error did not start from the beginning but at almost at the end of the month. on aug 30 it skipped a day in the reporting ( reporting 0kwh on aug 30) and placed the results of 30 aug on 31 aug.and is now running ahead 1 day as you reported. I sent screenshots of the webpages of the inverter. I offered them anaydesk acess via my PC, but they told me they were not allowed to do that .. at least I’m not the only one.. they will probably wait till more bugs pop up…

Even SMA’s own units they use for educational purposes have the same problem: https://www.youtube.com/watch?v=0-vZW9y4Nes

Go to 2:37 in the video.

The Day select box shows March 2, 2017 yet the date at bottom right which is in US date format (MM/DD/YY) shows 3/1/2017 which is the 1st of March. The time shown is 4:39 PM which is probably past the UTC roll over time so shows the NEXT day in the select box.

I also wish they would change the firmware to use International date format (YYYY-MM-DD) or at least provide an option to select how one wants to view it. I can’t see a setting for it under “Time settings”.

hilarious!

today I downloaded and installed firmware 1.3.4.R .

the date issue is fixed !

On my original SMA inverter early in June this year I updated the FW to 1.3.4R. Made no difference as far as the date issue was concerned for me. Later SMA claimed the problem was in the boot loader and that a small number of units had the problem.

They sent a replacement inverter as it can’t update the boot loader using normal methods. Still had the same date issue with the replacement and it also shipped with a very old version of the firmware but no matter how many times I tried to update it failed to do so.

Another replacement Inverter was provided (No 3). This came with 1.3.3R. I just checked and it’s now 1.3.4R. I checked the event logs and see it auto updated on the 16-September but I don’t think that is going to make any difference for me as I still think it’s going to be wrong. I will know later today around 2:30 PM when I refresh the boxes home page to see what date is in the select box.

SMA is claiming my issue to be a problem to do with UTC and that they need to fix it but 1.3.4R has been around for quite some now so fix can’t have been in that for my particular problem.

Just to add to the confusion is the FW version number shown in that video. It shows as 2.4.3R.

Refreshed the page after 2:30 PM and as expected the date shows the next day so not resolved my issue.

Still no software fix for this UTC bug. When I ask SMA Australia what’s happening I’m told it’s just a “Cosmetic” bug and does not affect power generation and they are still working on it. I agree with the last part part but the “Cosmetic” bit is simply ridiculous. I have to submit screen dumps to PowerSA on Monday and the date can be wrong so have to go into a long winded explanation of why that is and further complicate things, Yeah, just cosmetic, Right.

I’ve been having massive issues with Voltage Rise grid errors and Ramping causing losses in what I could be exporting. I don’t think it has anything to do with the SMA box but it shows up when I’m exporting power back into the Grid with many SMA grid errors each day so I’m loosing feed-in credits. My expected yields since the Winter Solstice have declined because of the constant grid problems caused by higher solar radiance. I’m now monitoring with my own Mains voltage logger and it can be viewed by anyone that has the link to the cloud logging site.

I’m following this up with PowerSA on Monday but when I went to capture the graphical day display today that shows the “Porcupine” power graph caused by all the grid errors I discover all the data is now gone! I’m led to believe the SMA box can only store 2 months of data. This is the 3rd box I’m on and was tested by SMA two months ago before install and checking back it’s two months ago it was tested. In itself this is not a major issue (but still poor design IMO) but the real problem is they are NOT using a circular buffer. As soon as 2 months pass the entire lot of power graph data is WIPED clean from the box!

Any good experienced software engineer knows that a circular buffer should be used employing the First In, First Off (FIFO) method. That way the last two months of data is always there by deleting the oldest entry first instead of just completely starting over every 2 months from scratch. It simply goes beyond belief.

Data is logged to the Portal but that is every 15 minutes instead of 5 you see on the inverter itself so not very useful as it’s not obvious when a grid error occurs

If only I could have my time over again when choosing the Inverter for my system.

Retired Embedded Software Engineer and R&D Manager.

Regards

Stewart

Finally, someone else has noticed the memory problem ! My unit is fairly new – only installed last October. Sometime last week, I noriced the historical data has disappeared !

Firmware is up to 4.00.55.R dated 08/06/22

So, after all this time, this issue has not been addressed.

I have yet to hear back from SMA Australia.

I have found that in the webconnect app, there is an item that switches on/off saving data to memory card. My default was on. But, as far as I can tell, this Sunny Boy has no memory card facility !

Shoddy engineering/programming and as a retired CPeng, I am not impressed at all.

I would like to put in an SMA if my ENA is irreparable. Only problem is they don’t make a 2kW version. I cannot install a larger one due to government payback laws. I may be looking for a new 2kW inverter soon, meanwhile the repair efforts continue.

There are a number of non-SMA inverters on the market that are 2 kilowatts. One SMA is involved with are Zever inverters. They aren’t considered as reliable as actual SMA inverters but are considerably cheaper.

If you are looking for a high end inverter, there is a Fronius Galvo that is is 2 kilowatts. It also comes in a “light” version that is a little cheaper and is likely to suit your needs if you don’t want to connect an appliance to a relay.

Can anyone tell me what the settings under “Device parameters -> Grid monitoring” the values should be set to for the Chinese model?

Those values on my unit show as:

Country standard Special setting

Set country standard ——-

Shouldn’t it have an Australian standard set? All the units I been supplied have been set like that and from some feedback from SAPN is that they don’t think it’s been set correctly. I can’t change the Grid settings but need to know what they should be set to.

does anyone know if there are more differences between the new SBx.o series and the old -TL german design. I have both versions operating : 4000-TL21 and SB4.0.

I had a (capacitive) ground leakage problem with the SB4.0 with 24 panels SF-170 total, only during moderate to heavy rain. the RCBO tripped. I measured the insulation >1000M at 1kV excellent, but capacitance was around 80nF per 12 panels. maybe the SB4.0 is creating more ground leakage than the 4000-tl21, or there is a larger difference between the thin film sf-1p70 and the yingli normal silicon panels.

I solved it with a compensation capacitor across the RCBO, not the most elegant method.

I have laughed at some of the posts here about the “dangerous” aluminium seperator on the mains filter inductor.

Really? Do you guys have any electronics knowledge at all?

There is no way that aluminium mount would be a problem unless you belted the inverter with a 14 pound sledgehammer.

Seriously picky review……seriously.

Hello John, with all due respect – you have it wrong. As a retired chartered professional engineer I have actively been responsible for designing switch mode power supplies to comply with CE requirements. That aluminium spacer is an instant fail – no argument.

I can report however, after checking my new SB5-41 that they now use FR4 PCB as spacers – so, the word must have gotten to Germany and it is now fixed.

For other SMA users, another change is that the inverter is no longer fan-less. My inverter certainly has a small fan inside. The WEB-UI even allow for testing the fan !

Hi sir mark, Is it possible to use other types of limiter rather than using SMA brand which is very expensive.

Hi Mark thank you for your article SMA German V Chinese

I am considering a solar energy system which includes a SMA SMA SB5.0-1AV-40 Inverter.

I’m certain this is a Chinese “assembled” SMA although can you confirm? But what I have noticed by examining your SMA inverter review ratings there has been a decline in reviews and star score particularly over the last 6 to 12 months. Is this your fear of the possible”quality” issues around Chinese “assembled” SMA or market conditions? BTW I have used the Solar Quotes for most of my research and I have found it educational, instructional and highly informative.

as I have both a SB4000-TL21 and a SB4.0 a found that they are very different in their behaviour. the most visible is the behaviour when power limiting is required,for example by feedin-limitation or frequency shift in an isolated AC coupled setting.

the SB4000 (and I guess the whole family as it shares the same softwhere and architecture) reduces the DC setpoint voltage of the input converter,such that the string current is maintained,but the voltage is droppped,hence less power.

the SB4.0 increases the voltage and the string current will drop,hence less power.this is the proper way to do it as the step to zero power is a soft one,while the SB4000 has a maximum string current flowing near zero power.

I did have TIGO optimizers in the SB4000 strings due to a palm that had grown over the years. what now happens is that the tigo tries to counteract the dropped voltage into more current,until the 15A input current limit of the inverter is exceeded creating an error 3801 in the inverter. so thre SB4000 is in compatible with optimizers.I discussed it extensively with SMA germany, there are no plans to change the software.my only solution was to swap the SB4000 for the other SB4.0 I had in the system.

What is the difference between the AV-40 and AV-41 models?