Galvanised roofs with aluminium-framed solar panels attached will rust. Read on, and I’ll explain why this happens, what to do if you already have a galvanised roof, and how to buy a shiny metal roof that won’t rust when you add solar panels.

Solar Can Eat Holes In Your Roof

While all roofing will eventually rust away, given the right conditions, a solar array can drip holes in a new or old galvanised roof in perhaps ten years. Sadly, not many realise until it’s too late and the rust stains have already appeared.

Coatings Protect Iron From Corrosion

If you remember your school science class, you might recall the galvanic series, metals that are more or less noble. Put simply, there’s a pecking order of metals and alloys that are more or less corrosive to each other.

When different metals are combined, and an electrolyte is added, they create a battery. Given some time, the less noble metal can corrode to the point of disappearing altogether.

Rainwater is the electrolyte, and runoff from the aluminium solar panel framing forms aggressive corrosion where it drips onto the galvanised roofing material.

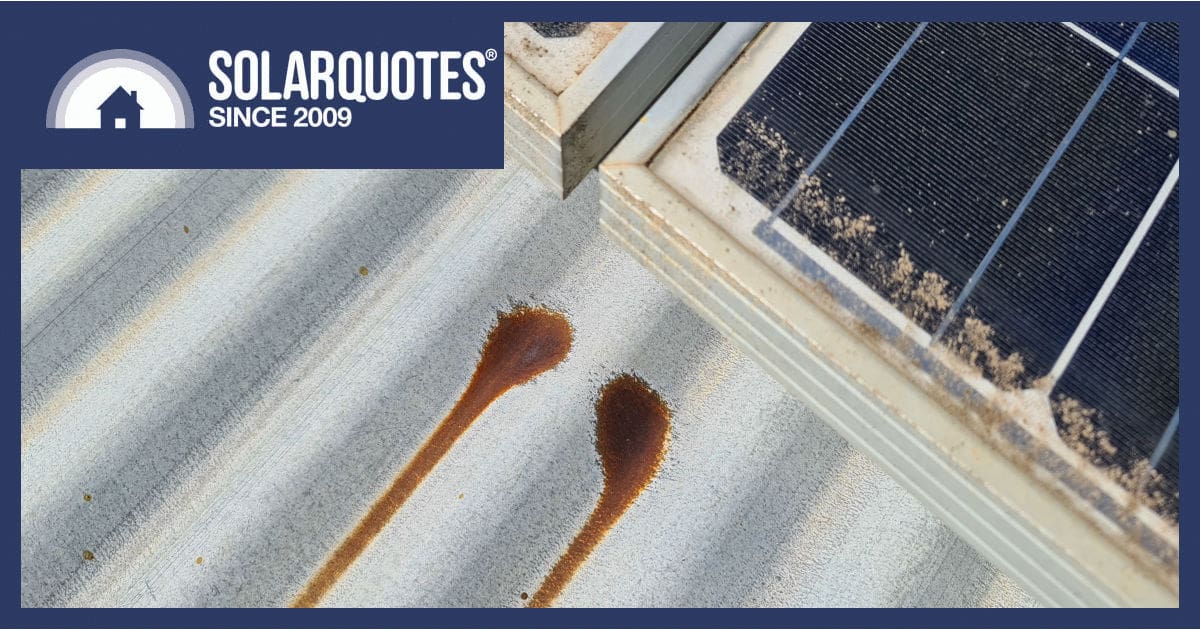

Solar panel runoff can rust through your galvanised roof in no time

Australia Loves Galvanised Corrugated Iron

You don’t have to be a roofer to recognise that the Australian landscape isn’t well suited to slate or timber shingles. As a solar installer, I appreciate that.

Our soils aren’t well suited to sheep either, but that didn’t stop us from riding the wool industry to economic prosperity. We sent wool to England, and they sent back tough, lightweight building material. Corrugated iron built the farm houses and shearing sheds, these temples dedicated to hard work.

Runoff from an old solar frame has caused this rust

These Days, It’s Called Zincalume®

When you see the adverts for Colourbond steel, it’s paint applied over a 55% aluminium, 43.5% zinc, 1.5% silicon coating.

Aluminised steel doesn’t have the lovely spangled appearance of hot-dip zinc, but the most important difference is its aluminium content, which means solar doesn’t affect it.

Zincalume and Colourbond® are immune to solar runoff because they are very similar materials and don’t form a voltage potential.

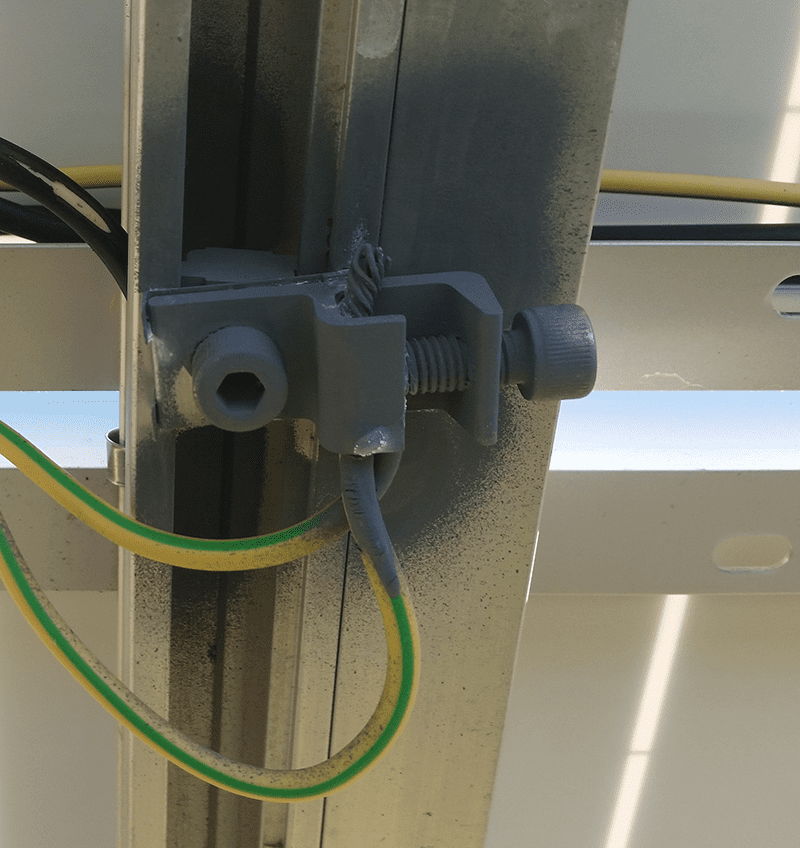

Interestingly this screw hasn’t suffered the same way the galvanised roof has.

For Further Reading

Wikipedia will tell you all about galvanic corrosion, but if you’re interested in how to detect signs of or treat ague, apoplexy, delirium tremens, rupture, snake bite, sore feet or sunstroke, then I highly recommend having a look at the Lysaght Referee. It’s an amazing publication. There’s even information about steel roofing.

Lysaght’s Referee. A celebrated piece of Australiana. I think we need to suggest solar irradiance be added to the general information section.

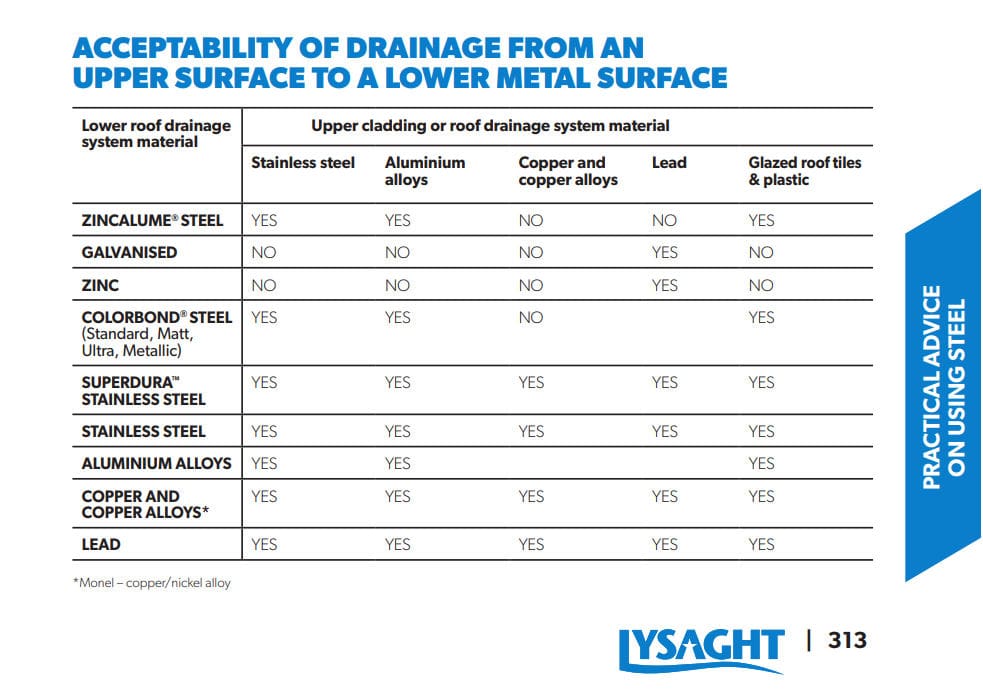

Excerpt from “The Referee” where Lysaght says NO

Repairs Are Both Simple & Ineffective

If they encounter a rusty galvanised roof, most electricians will shrug and acknowledge it’s just physics. They can’t prevent it, so removing scaly rust with a wire wheel or grinding disc is the first step. Then, a coat of zinc-rich paint is as good as it gets.

All earth connections on a solar array must be sprayed with cold galv paint. It is a legal requirement to prevent dissimilar metals in earth connections from corroding.

Coastal Environments Are Aggressive

Adding salt to the situation just makes things worse. It’s why some solar panels aren’t even warranted for installation near the coast, while reputable framing companies like Clenergy recommend washing down the roof regularly.

While it sounds a little obsessive, there’s actually good reasoning for flushing salt off. It’s not commonly understood, but “sheltering” can make corrosion problems much worse because salt sticks to surfaces that don’t get much weather.

Roofing screw corroded through a lap join in corrugated sheets

What Preventative Measures Are Available?

There are some pretty amazing paint and spray-on membrane products available these days. Some claim to have heat-reflective qualities, while others are just about waterproofing or extending the life of existing cladding.

My personal experience with a traditional bitumen-based stuff called brushable hydro seal has been very good. Protected from UV sunlight inside a rainwater tank, it sealed a heap of holes for a dozen years. If you have a rusty patch on the roof, I’d recommend it as well, even if removing all the existing rust and scale isn’t possible.

If you have an existing galvanised roof, I wouldn’t hesitate to paint it before a solar installation. Preserving the galvanising you have now is much better than trying to paint rusty steel later.

RSS - Posts

RSS - Posts

Sounds to me as if installers are not using Duralac or similar when they mix the two metals or a perhaps a physical barrier which has been SOP when installing rigging on boats as long as I have been aware and separate from salt water issues.

Hi Chris,

Many solar mountings come with EPDM rubber pads to separate and seal the legs from the roof, and screws form the legs, but this still doesn’t stop the corrosion from run-off seen in the header image.

Yes but where the screws touch is what I always understood to be the problem, so the rubber mount stops the frame touching and the anti corrosion paste as appropriate was to prevent I think electrolysis between the screws and the other metal. Forgive me if I am technically incorrect but that was the way I understood the need for the “dipping the screws”.

I’m surprised to hear that galvanised corrugated sheet has survived this long!

Even before I studied building design, I just couldn’t work out why anyone would choose to put concrete tiles on a roof, it must be the dumbest roofing material. When we built our house from plans of a display home, the only change was to a colourbond roof.

As a metal tradie, I knew a little about noble metals and once fabricated an aluminium tank for a boatie, who supplied the aluminium filler neck, with a shiny brass cap! I told him what would happen, but it got put on, and one month later, I’m very carefully heating it loose!

Hi Eric,

Boaties love brass don’t they. You’ll probably like my articles on tile roofs if you search the blogs 😉

Hi Eric,

It must have been at least 12 months ago that we had a hailstorm, here in Port Macquarie, and since that time we have seen most houses with Zincalume or Colourbond roofs, in our area, and further afield, being replaced.

58 years ago I trained in carpentry and joinery and the gal. roofs in those days could just about handle the weight of a man.

The modern metal roofs appear to be very thin, and I am thankful that we have a concrete tile roof that has been sealed and pointed correctly.

No sign of hail on the paint work.

Bob

Hi Bob,

Old corrugated iron didn’t have much tensile strength, I’ve seen it laid on the ground and cut with a long handled spade. It’s lovely to handle and the only thing available like it now is the thicker 0.52mm “curving iron” which is used for bullnose verandahs etc.

New corro may be thinner (0.42mm) but it’s much stiffer and makes a loud “snap” noise when you dent it underfoot. It’s also easy enough to tear form one edge to the other if you start with a nick from your tin snips.

I wouldn’t have a tile roof if you paid me 😉

https://www.solarquotes.com.au/blog/roof-tile-problems-solar/

What authority or standard etc should I quote when raising the requirement for the zinc rich paint on earth connection wires?

Hi Matthew,

AS/NZS 3000/2018

clause 5.5.5.3 Protection against corrosion

Earthing conductors and any associated fixing devices shall be protected from corrosion, including the effects of moisture or contact with dissimilar metals.

You scared me for a bit there, Anthony, but remembering that Colourbond is Zincalume under the paint, lowered my heartrate again.

Here, the Colourbond colour is “Whitehaven”, with an albedo of around 0.77, i.e. 77% reflective. Mind you, following Finn’s philosophy, there are only scraps of roof not covered in panels.

Like you, my dear old dad used Hydroseal for half a century to extend the life of galvanised iron tanks. I’ve put in 190,000 L of poly tanks instead. We’ll see how that goes. There’s a Vinidex datasheet saying that their PVC stromwater pipes are OK for potable water, but I drain the U-tube whenever water has stood in it for a stretch.

The ideal metal for seawater cocks and the like seems to be Aluminium Bronze. I alloyed some up many years ago, melting it in a DIY crucible furnace. The thinner sections were chill cast, and surprisingly hard. A file just bounced off. (There’s just a few % iron in it to get the result.)

Dad also added decades of life to rusty ancient galvanised iron by whacking aluminium paint over untreated light rust. Feeding only the laundry tank from that roof avoided aluminium in the drinking water. I suspect that the localised rusting was due to his DIY brick chimney clearing the roof by only a foot, resulting in acid woodsmoke flow sticking to the roof in light winds.

Hi Anthony,

Interesting article indeed!

I’ve a solar system on my corrugated metal roof for 13 years and am now just in the process of upgrading to new bigger panels, inverter and batteries etc!

I have spotted some seemingly superficial rusted spots and areas but put this down to natural roof ageing?

My questions are:-

1. How do I tell if I have mere galvanised corrugated iron or zincalume steel?

2. Can I just treat the rust areas if only superficial with the products mentioned above before replacing the panels?

3. Are black anodised panels any better and less corrosive to a corrugated roof?

Look forward to your thoughts.

Regards,

Paul

BTW: Don’t/shouldn’t the solar suppliers/installers advise of any such issues at or before install!? 😮

Appreciate anyones thoughts or suggestions etc on my questions 2 and 3?

Regards

NO reliable study evidence to support this !!!

Hi Dave,

Did you read the article?

https://en.wikipedia.org/wiki/Galvanic_corrosion

Our if you don’t believe that information from Anthony, you could do one of the following fun experiments:

If you own a small tinny ( Aluminium hull) chuck some lead shot into it and don’t wash the sea water out after use.

Or

If you have a an electric storage HWS just remove the sacrificial anode and wait a year or 3.

Or

If you have old amalgam fillings, have chew on some aluminium foil.

This is a very timely and interesting article for me. I am planning a significant solar installation for next year (aiming for 18-20 kW + battery) with the aim of future proofing for energy. We are going all out to upgrade the house for energy efficiency – windows to Double Glazing, upgrading ceiling insulation (to achieve R6 or 7) and have been looking at the roof in relation to colour to improve reflectivity. Currently have a heritage red Colorbond roof about 35 years old, which is sound but the purlins underneath are about half 30 year-old and OK, and the rest 100 years old and wobbly to walk on. Have been thinking about the need to reinforce the roof timber and go for a more reflective roof. I had recently looked at reflectivity of both galvanized steel and zinc-alum. It is actually not easy to find this data on the internet – there is more authoritative information for the range of colorbond colours. My logic was they are both shiny and a bit cheaper than new colorbond! Looks like galvanised is out based upon your advice. I would appreciate and comments. Thanks

Hi Mike,

Zincalume is probably the go for you but white colourbond is worth investigating as it might even be better?

I would also investigate blanket insulation under the cladding but be aware you may need to control condensation.

There’s a lot of helpful people here ;

https://www.facebook.com/groups/996387660405677

go for “white” colourbond rather than zincalume for longevity .

I have 30 year zincalume roof and wishing I had put on colourbond

According to the manufacturer light coloured colorbond (White/Surfmist/Southerly etc) is a LOT more reflective than zincalume

According to roofers zincalume becomes a great deal hotter than colorbond on a sunny day

Not my opinion – just what I have heard

How many non-Zincalume roofs are still around? We had a new garage and granny flat constructed in 1993, and Zincalume was specified. No sign of rust since solar panels were installed in 2011

Is there any galvanic corrosion danger from Clenergy Klip-Lok mount feets on metal roofing?

Hi Sam,

Clenergy are pretty diligent about making sure their solutions are good. Some cliplock feet have EPDM gaskets but the universal type brackets are just anodised and they claim there isn’t enough surface area to hold water and cause problems.

Hi Anthony

Thanks for raising awareness of this issue. As heritage architects we are familiar with ‘drip spot corrosion’ of galvanised roofing. We have even seen corrosion where runoff from a decktite aluminium trim drips onto a galv roof. We are also still specifiying galvanised roofing for conservation projects, typically referred to as heritage galv. But we keep zincalume and aluminium well away.

Paul, it can be challenging to visually distinguish between zincalume and galv. We look closely at the spangle and colour. Looking at Anthony’s images, the first two have a distinctly zincalume (aluminium) appearance and colour. It is hard to be sure from photos and there is no doubt about the corrosion. We also know that there was a line of galv being distributed a few years back that had a very fine spangle, just to make the task more challenging.

Images 3&4 are obviously galv. We notice that galv has an overall blue-ish colour cast.

To compound our consternation, we have just bought a home with recently installed solar panels. The roof was white colorbond installed in 1974. But the colour has all but chalked away, revealing a galvanised metal substrate. An earlier iteration of colorbond, before the zincalume substrate became standard in 1976…

Thanks for your reply.

However ALL 4 photos show rust!?

Are you saying both Galvanised Iron & Zincalume Steel Rust from panels? :O

Hi Paul,

Galvanic corrosion will affect galvanised roofing when it sees run off from aluminium solar framing.

Zincalume roofing (including colourbond) is not affected by run off from aluminium solar framing.

In any case this is a slow process. I’ve put solar on hundreds of galvanised roofs and they’ve not been a problem. Though they may begin to rust, in many cases it doesn’t significantly shorten the life of a roof that’s already 50 years old.

It’s simply worth keeping an eye on.

Hi Anthony,

Thanks for that.

If we see any rust after taking off the old panels I think we’ll use some spray Gal. in a can or better depending on the amount.

We’re getting the new black anodised Vertex N so hopefully might be better than the silver frame too?

Cheers,

Paul

About 10 or 12 years ago I wrote to Renew magazine to question why solar panels were installed so close to the roof making it very herd to clean the leaf litter from behind the panels. Trotting leaves form an acid that will corrode steel and penetrative paint, see car bonnet protectors left uncleaned.

I notice that some installers are now running their roof surface racking vertical to fix this problem. The cowbboys will still do the quickest and easiest way.

Hi Richard,

Old systems sometimes used very low “unistrut” type rails but ordinarily portrait panels with horizontal rails is most efficient.

As panel frames have thinned many have found the “clamp zones” are fussier and have turned to landscape panels with vertical rails for structural reasons. It’s always been better but takes longer and uses more parts.

Easier cleaning is a happy coincidence.

In the 1980’s I was the Telstra Technical Officer looking after 10 or so solar powered radio telephone sites on various Torres Strait Islands.

Up until about the mid 1980’s these consisted of a single channel AWA radio feeding into an AB button pay phone.

The radio equipment was housed in a heavy gauge galvanised iron hut about the size of 2 outside dunnys. The solar panels were made up of 6 (six) watt panels mounted on galvanised iron bearers, which were in turn bolted to the galvanised iron roof.

Distance from the sea varied but a decent footy kick or hit with a cricket bat away was the norm.

There was no dissimilar metal corrosion problem as the design prevented water pooling.

Hi Anthony

Thanks for a great article raising this important issue.

I want to install solar panels and my ‘historically significant’ house is in a heritage controlled area in Melbourne.

I was planning to replace the corrugated roof before installing the panels.

The council says Z600 heritage galvanised steel must be used for the new roof otherwise a permit will not be issued.

I have two questions

1. Do the solar panels themselves also have this issue, or is it just the racking, framing and fixings?

2. Do alternatives exist, for racking & framing in a regular house installation, that will not corrode galvanised steel?

Cheers

Hi Lee,

I’d reach out to the council anonymously, send them the article & ask if the heritage people would find a zinc roof heretical.

If they insist it’s galv or nothing I’d point out they’re restricting your ability to install solar.

I’m all for heritage protection and I understand that colourbond isn’t always the best but we *need* more solar.

Perhaps ask them if painting your new galv roof is acceptable… I’ve seen councils force people to paint a zinc roof to match an adjacent zinc roof!

Failing that, install solar anyway & just keep your eye on it. Not all roofs seem to suffer the same way.

Hi team

This is very true, I got solar put on 7 years ago by one of the top 10 from here and they did a fantastic job apart from making me aware of this known fact. I went into my spare room the other day to find a stained patch on the ceiling. I thought how can there be water damage as nothing can damage the roof as I have 22 panels covering that side. I went up to have a look and found rust on every sheet where every panel ends. The roof though old had no rust at all. Now I need a serious restoration and or replacement, which will cost up to $20000. The other side of the house with no panels is rust free. 7 years on the system and is still working great but, my spare room is only a few summers away from becoming a water feature. How do I move forward and who is liable in this situation. I called the rep who sold me the system who no longer works for the company and admitted there was no disclosure that this could happen. Obviously if I was made aware of this issue before installation I would have paid to get my roof sprayed. Please advise how a consumer in my situation can move forward. Who will remove the panels so we can assess the extent of the damage and who will fund the rectification.

Thanks

Hi Jonathan,

I haven’t had first hand experience with rectification beyond a bit of wire brushing and some cold galv paint, as detailed in the article.

Have you spoken to the installation company yet?

Let us know please.

Thanks for your reply

Yes they are waiting to see photos