Andrew Reither from PowerPlus Energy getting the hang of commissioning

Have you heard the Whispr?

Australian battery maker PowerPlus Energy has a stackable battery inverter combination now available to fully support 3 phase systems.

So is it any good? In my humble opinion yes. Read on while we explain why in this installation review.

For many years PowerPlus Energy have been beavering away in Melbourne, making some venerable 48 volt batteries that work brilliantly with inverters like Selectronic SpPro, CT&E, and Victron. On a tight budget you could also use a cheaper Deye/NoArk, possibly even GoodWe or Solis inverter to pair with them.

The physical format is a “server rack” style so there are a number of indoor or outdoor rated enclosures to house them in, with Amphenol connectors to make the connections plug and play.

However the 48 volt standard used traditionally in remote area power isn’t favoured by modern lightweight grid hybrid systems. Sungrow gave up on it a few years ago, Fronius never tried. It’s simply more efficient to use higher voltage and less copper for the same1 power output.

PowerPlus Enter The Grid Hybrid Market With Help

Facts are that 90% or more of the world’s battery cells come from China.

So to be competitive, PowerPlus Energy have teamed up with Renox2 to deliver a fully imported, stackable solar and battery inverter. However it’s been tested, CEC approved, branded, monitored and most importantly supported locally by PowerPlus.

Simplicity Is The Ultimate Refinement

I’m not waxing on about the appearance of these whitegoods – it looks fine and should do for years, as there’s no tacky plastic covers.

However there’s some Tesla elegance to the offering, in that you get a choice of one size (13.37kWh) or you buy up to four more complete units to reach 53.5kWh.

They will work in unison while the grid is up, however during an outage the backup circuits cannot be combined together in parallel.

Now a 7kW inverter shouldn’t be sneezed at. It’ll cover most average houses but isn’t king of the kids when others offer 8 and 10kW units. However it can be commissioned as a 5kW machine if your poles and wires people demand a modest connection capacity.

More recently though, new firmware has been released to make the Whispr work with a 3 phase supply, using 3 units to deliver balanced output which keeps the network boffins happy.

Unlike Tesla though, Whispr now offers true 120° synchronous backup for 3 phase loads.

It’s a pretty clean installation.

Trading Experience For Current Knowledge

While I’m no longer “on the tools” installing solar every day, I regularly help out at Solar Training Center as they put students through their paces. Supervising the practical day at the end of the week means I can have detailed conversations with 20 different electricians who are on the coal face.

Some are fresh faced and yet to lose their lunch on the solar coaster, others are old and wisened but finally doing the paperwork to have their solar qualifications endorsed for battery or off grid work.

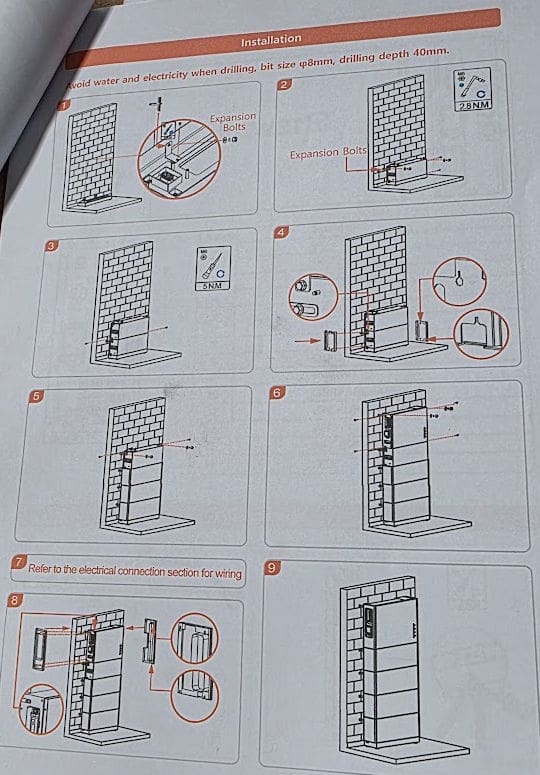

Unboxing and setting the base plate in position.

We all end up learning something, even if it’s just amusing tales about job site disasters. However there are priceless encounters too, like meeting technical support people for manufacturers you only ever encounter on the phone normally. It’s fascinating when they’re ex-Huawei employees with direct insight into competing Chinese brands for instance.

PowerPlus Energy Bring The Goods

Unlike most of the industry, the free merch PowerPlus Energy give away to class every month is stuff installers will fight over. Forget about the rubbish hats, keyrings and bottle openers, what trades want are fine point markers and Fasty straps for tying down ladders.

PowerPlus Energy simply don’t offer bad quality bin filler, which is why I’m confident they’ve done the due diligence on the products they sell.

These images were 8 minutes apart but you’d take a little longer if there were masonary fixings to put into the wall.

Fast Installation Works

When we unboxed the new unit I was sadly unsurprised to find it packed in plastic foam. Fronius and Sungrow deserve credit for using recyclable cardboard.

The contents looked well made and the boys soon had the base plate down and a couple of batteries stacked on it. Of course being manly men with an unhealthy disdain for instruction sheets, they missed installing the first pair of wall brackets.

Step 1, read the instructions and put the bottom bracket on.

Despite that minor setback, the whole package of 4 batteries and inverter went together in 8 minutes.

Improvements To Make

Securing the blocks together are simple slotted brackets with different sized bolts, but more thoughtfully I’d expect they’d use 8mm hex heads, so you only need one tool in hand to zap them together?

Some simple changes, like standardised fixings, can make a huge difference to install quality.

And if you can imagine a different wall behind this unit, you can easily see that some extra articulation in the brackets, as depicted in blue, would be priceless to avoid a mortar joint or weatherboard lap.

This cover needs a little extra clearance but otherwise the fit and finish is good.

At least the WiFi dongle is accessible but also well protected in its own recess.

Wiring Is Straightforward

The Whispr has three solar input channels for design flexibility, and plug connections for AC input and battery backup output.

The unit can also cope with a generator input (through a changeover switch to the grid port), making it a good fit for somewhere that might suffer a prolonged outage with poor solar – like post cyclone Queensland perhaps.

Terminals are easy to access and won’t encourage anyone to wrench the cables around just for aesthetic reasons.

Another important feature are the AC and DC isolators, easily accessed without having to remove any covers.

Having recently fielded a call about shutting down a system for a reset, it had never occurred to me that many people have so little idea experience. The jargon on shutdown labels is confusing enough, but when they can’t find switches, because they don’t even realise there’s a cover or gateway door you need to open, it’s just ridiculous.

Like any series connected hybrid inverter, I would insist your backup circuits are wired through a bypass switch. The Whispr has a backup capacity or 22 Amps/5kW or 30.5 Amps /7kW so it will manage a decent load.

You can have more than basic “lights and fridge” blackout protection, but it’s not designed to backup a whole home.

However if you install more than one unit, there is more capacity available, so divide the switchboard up and you could keep the air conditioning going with one battery, TV and WiFi on another.

Bang For Your Buck And Well Backed Up

In recent days I’ve seen 3 different people asking about what to do with their better than bargain basement Qcells hybrid battery system. While they had all the features and a great reputation for quality, nobody saw it coming when Qcells pulled the pin.

Now the parent company has ceased operations in Australia, existing systems still under warranty are poorly supported, if at all.

I think the Whispr represents a solid package and with PowerPlus Energy to stand behind them it should be a pretty good value.

Perhaps the best recommendation is the warranty document. Page 1 of 1 means there’s no hiding things in the fine print and nothing is lost in translation.

For more on PowerPlus Energy’s batteries and customer verdicts, read our review page.

RSS - Posts

RSS - Posts

Anthony,

Ya can pooh-pooh 48V all day, but mine “backs up” at a 24 kW full-sun limit, 16 kVA night-time. It’s currently pumping 8.8 kW on the DC-coupled half, with the AC-coupled side throttled to zero because there’s not enough load to warrant it waking up. It’s powering two houses and charging the BEV.

The fat cable phobia is a Furphy, I submit. There’s six thumb-thick battery cables here, two to each 15.5 kWh battery, but it’s only a metre or so to the battery inverters. They look good. It’s the 230 Vac which is run about the place when designing optimally.

OK, 48V is a safer voltage, but a scarier current – when the installer forgets to tighten the last isolator lug bolt.

That said, if Victron had 72, 96, or 144V inverters, I’d have gone for the resulting slightly higher inverter efficiency that can be achieved. But 48V allowed me to DIY the battery, at $390/kWh 2 yrs ago, no subsidy. And the monitoring beats all. That was the decider for me. It’s industrial strength.

Well said Eric and from your perspective you will, as you must; support what you see in front of you, which is servicing your needs perfectly and in every way. To summarise: well done and great decision making looking back.

But stepping out of your shoes for a minute, and stepping up to the lectern to deliver a masterclass lecture in “new age power electronics design architecture” to a gaggle of electrical power undergraduates; I bet you might quickly rewrite your presentation regarding 48 V verses higher Voltage power systems, to avoid being embarassed.

In my earliest days as a power systems artificer in the Navy in 1965, the standard voltage in my world then as an apprentice, then tradesman, working daily with light and heavy machinery was 400 VDC.

In those days 48 VDC came into acceptance in the civilian world only because no licence was required by anyone, to work on DC systems up to 50 VDC.

48V was a default standard rather than an engineering one.

Lawrence Coomber

Hi Eric,

48V is fine if you ask me. It gets impractical as the inverters get larger.

However a Selectronic SPMC482 7.5kW (18kW surge) is a brilliant grid forming machine. It’ll eat your Victron for breakfast 😉

It’s the 12V caravan club I just cant fathom… with 3kW inverters and 300A continuous current to cook breakfast. They’re mad.

Anthony I have hands on research and exposure to this subject.

Most notably from working and learning alongside Chief EV Battery Scientist Erik Spek (Ontario University) at the Society of Automotive Engineers Laboratory in Detroit in 2017.

Along with about 30 other US EV Engineers for a 2 week course in Safe Handling and Construction of HV EV Battery Stacks, it was no surprise that we were working on > 900 VDC architecture then, and given first hand insights from prominent EV scientists about the importance of understanding the fundemental molecular science, behind the two types of circuits, and why only one will be focussed on for both EV and General Battery Storage applications moving forward.

Lawrence Coomber

Joule Heating and Combustion Precursors

The fundamental heating mechanism is Joule heating:

𝑃 (heat) = I2R

This shows the quadratic effect:

Doubling current quadruples the heat generated.

Voltage does not appear in this formula.

Critical consequences of I²R heating

In high-current systems:

– Conductors run hotter

– Insulation softens, carbonises, or melts

– Oxidation at connection points accelerates

– Loose connections become resistive hotspots

– Arc formation risk increases dramatically

Once insulation begins to degrade:

– Carbonised insulation becomes semiconductive, causing leakage paths

– Elevated temperatures can exceed the auto-ignition point of plastics, dust, or nearby flammable materials

– Fire propagation becomes highly likely.

Thus, temperature—not voltage—is the primary precursor to electrical fires, and high current is the dominant driver.

You are starting to see more and more stories everyday about this subject.

Lawrence Coomber

Hi Lawrence,

Thanks for your very thorough summation, it’s very helpful.

Having spoken to the good people at PowerPlus, they have pointed out that once lithium chemistries start getting hot (45ºC or more) then the electrolyte begins consuming the cathode and life expectancy plummets as a result.

I might see if they’ll clarify exactly how for another article.

Well Anthony, whilst what you have been told is not “literally correct” its basic message and technical emphasis on cell ageing though is sound.

From a practical perspective rather than laborious chemistry lesson though, the bottom line is this: Battery cell degradation (all chemistries) follows an Arrhenius temperature relationship.

Simple maths and simply put means that: every 10 degree rise in cell temperature roughly doubles the rate of ageing. A table would look like this: Cell Temp. 25 Ageing Rate x1 (Baseline); Cell Temp. 35 Ageing Rate x 2; Cell Temp. 45 Ageing Rate x 4; Cell Temp. 55 Ageing Rate x 8; Cell Temp. 65 Ageing Rate x 16.

Lawrence Coomber