Unless your house was built in the last couple of years, installing a house battery will likely require at least some switchboard upgrades.

It’s a basic electrical regulation so why are some solar battery salespeople ignoring the need and setting expensive traps in the process?

Does Your Switchboard Require An Upgrade?

At the heart of this problem is the humble safety switch. They’ve been around for decades but since 2023 the AS3000 rules mandate they shall be updated to the latest type if any significant work is done on your wiring.

Installing a solar battery means you are changing the supply, so every downstream circuit needs a compliant Type A residual current device. No ifs or buts.

Of course this can be expensive. Switchboard rebuilds start at $1000 and that’s a significant price differential when your competition is quoting on a power system without including all the required work.

So customers are rightly upset when there’s a hidden premium to pay on install day, because the sales team conveniently forgot and the electrician is obliged by law to do the work.

Make sure to confirm with your installer whether an upgrade is needed before you sign on the dotted line.

Safety Through Balance

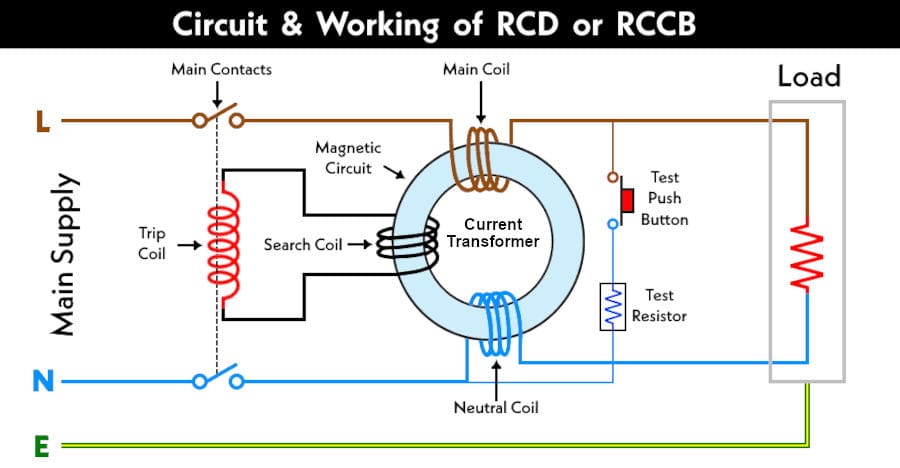

Say you have a toaster that’s using 8 amps of current. What flows out to the appliance on the active wire must come back via the neutral wire. If you drop that toaster in the bath, some of the current will “leak” out of the circuit.

The imbalance, measured between active and neutral by the current transformer, will throw the safety switch open, disconnecting the supply.

Thanks to electricaltechnology.org for the image

It doesn’t take much to stop your heart, so RCDs will trigger at only 30 milliamps.1 So whether it’s the toaster using 8 amps, or my Dad’s welder using 28 amps, the circuit only has to leak a tiny 0.03amps to trip the RCD.

Name Calling Begins Here

“Safety switches” do pretty much the same thing. They go under a few different names, like earth leakage circuit breaker (ELCB), residual current circuit breaker (RCCB) residual current device (RCD) or residual current breaker with overload (RCBO), so the names are often confused.

At 40 odd years not the oldest I’ve seen, but this outlet gave earth leakage protection to several others in the house.

Of course “pretty much” isn’t a term covered in the rules and there’s nothing like a room full of pedants electricians to start quoting chapter and verse from “the good book” or more precisely AS/NZS 3000:2018 Amendment 2.

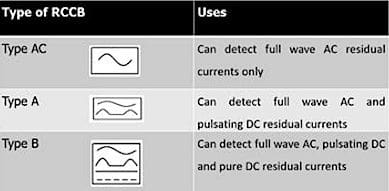

The difference is in how they detect a fault:

-

ELCB (Earth Leakage Circuit Breaker – usually “voltage-operated”)

-

Senses voltage rise on the earth/PE conductor relative to the installation earth electrode.

-

Trips when the earth conductor reaches a set voltage (e.g. 50–100 V) due to leakage to earth.

-

Needs a good, continuous earth connection to work at all.

-

-

RCCB (Residual Current Circuit Breaker – a type of RCD)

-

Senses current imbalance between active and neutral using a toroidal current transformer.

-

Trips when the residual current (difference between phase and neutral) exceeds the set value (e.g. 30 mA), regardless of where that leakage current goes.

-

Does not rely on a specific earth voltage or even an intact earth conductor; it just needs the active and neutral to pass through the sensing core.

-

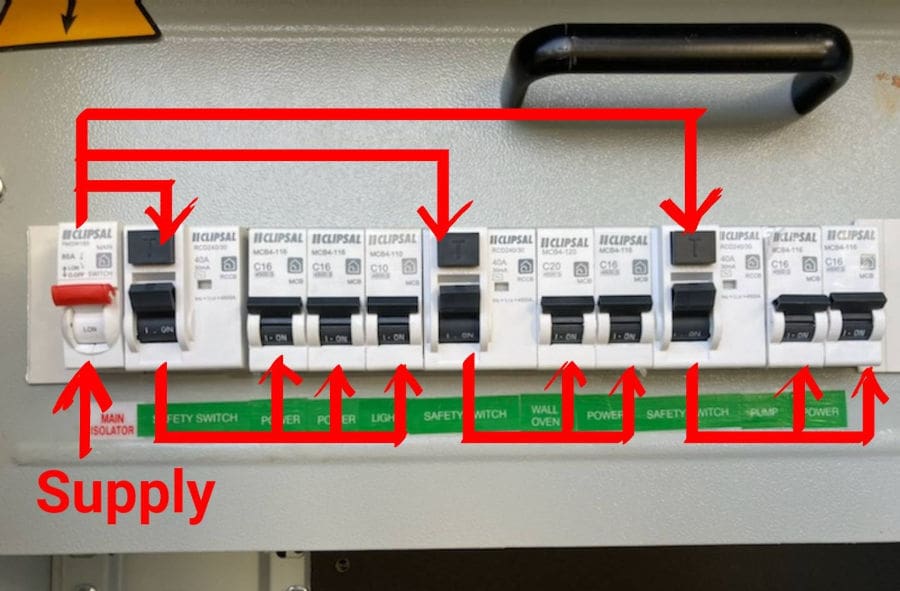

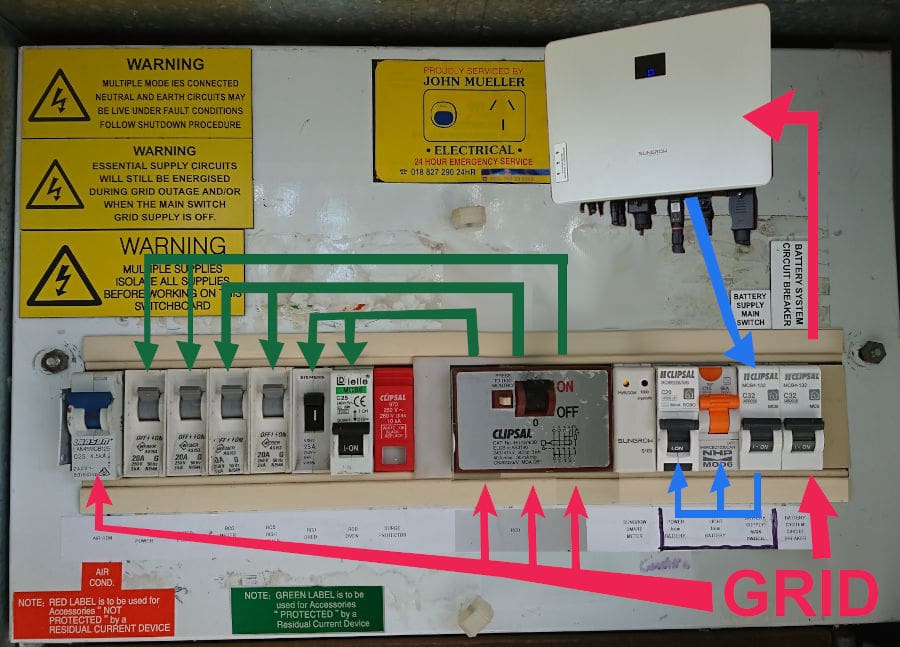

A cheap builder’s new house switchboard has 2 pole RCDs for earth leakage protection. Downstream of these are two or three standard circuit breakers to protect the final sub circuits from overload.

If you want “whole home” backup in the board pictured above, sadly everything except the red toggle is likely going in the bin. Installing 7 RCBOs will free up 6 poles you may need for consumption metering, solar circuit breakers or an EV charger.

AC/DC

Now everybody is rocking solid state power handling equipment, we need devices that will cope with both kinds of music.

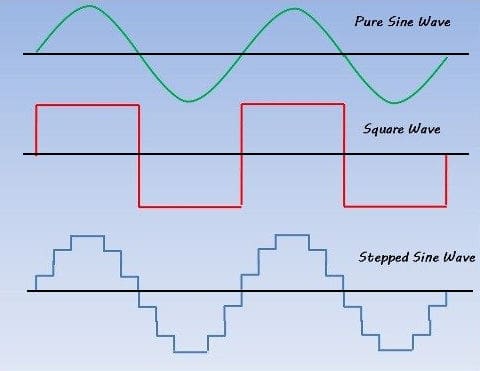

Ordinary alternating current (AC) powers things with a predictably shaped wave, which ebbs and flows 50 times per second. These smooth curves make up the grid frequency of 50 Hertz, which keeps your oven clock on time.

However the modern world is full of batteries which need direct current (DC), solar panels which supply DC, and variable frequency drives which power LED lighting and flexible appliances. For instance, when you see an air conditioner with an “inverter” sticker or a ceiling fan with a “DC motor” then it relies on a solid state power supply.

Remember when your electric keyboard or portable home phone(!) had a plug pack on the wall, which felt so heavy? Like it was solid metal? Well it was. There was a steel and copper transformer in there.

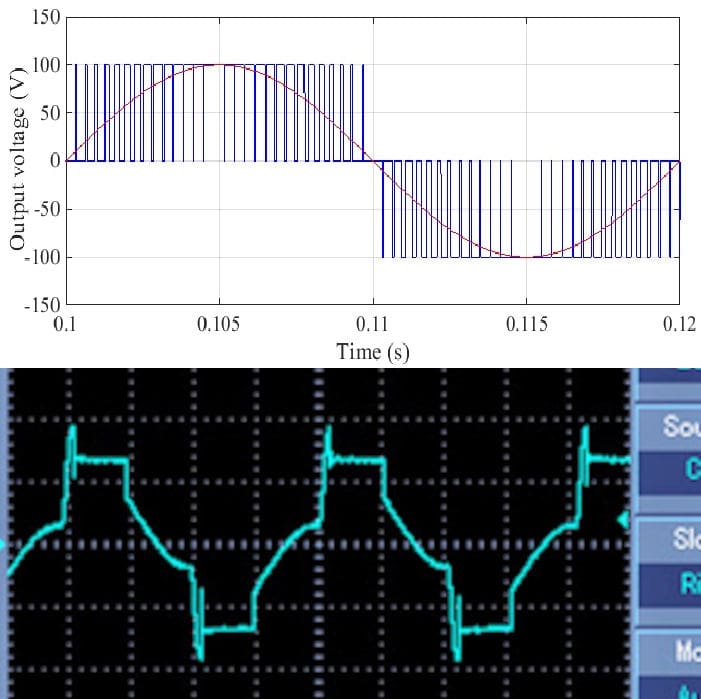

The green curve is what you get from mains electricity or a transformer. Inverters make less refined “waves” depending on the need.

These days your cordless everything charger has comparatively little metal inside it. It uses lightweight high frequency switching devices to boost or buck voltages. Conversions are done by incredibly fast electronics, chopping up the nice smooth AC coming from the wall into all kinds of crazy square waves and reforming them into just what the technician ordered, almost.

The thing is that solid state power supplies often leak a bit of electricity here and there.

In theory, the top image shows you can switch things on/off really fast to make waves, but in reality, things can get lumpy, spiky & leaky, as seen in the lower oscilloscope measurement.

Type A versus Type AC

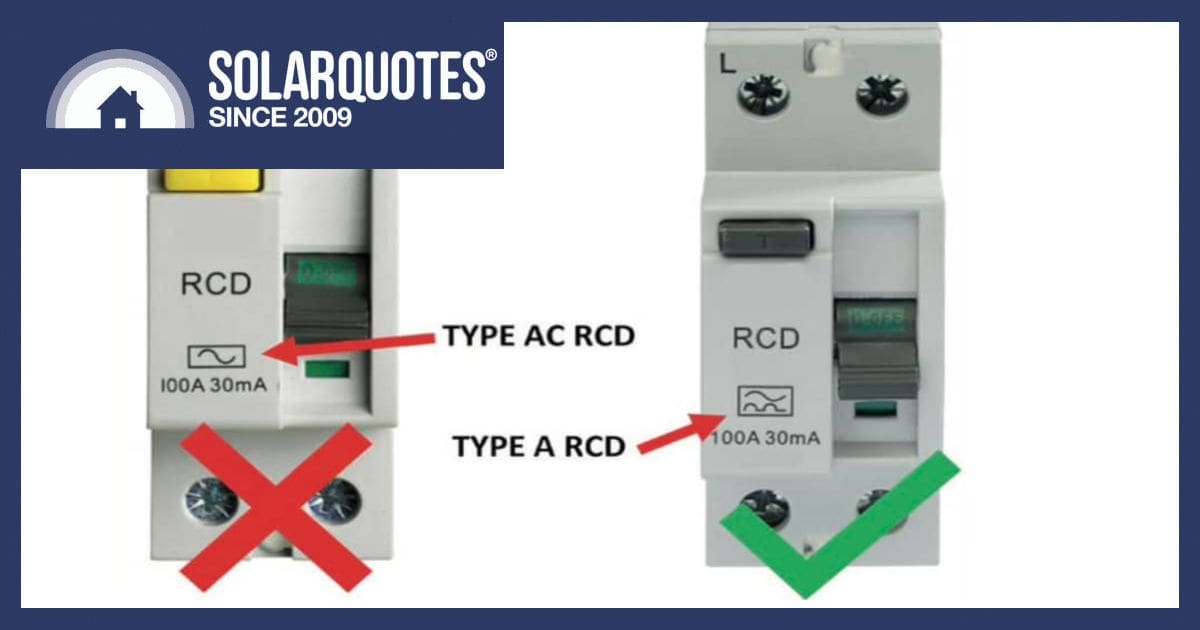

Older RCDs called Type AC can cope with nice smooth AC waves but they are effectively blind to DC pulses which might leak from solid state power handling equipment.

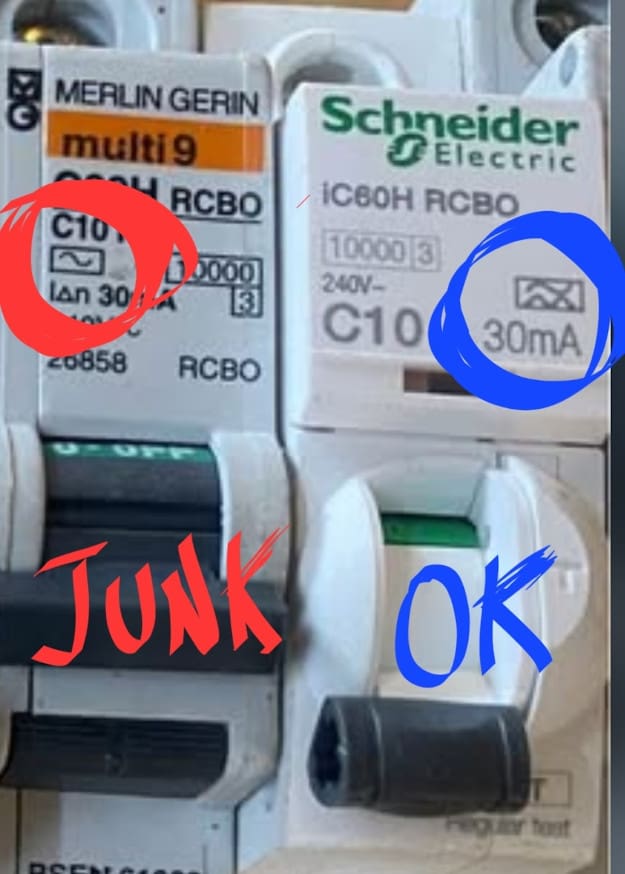

Newer Type A RCDs will trip if they see a 6mA DC pulse on top of the standard AC waveform.

While Type B RCDs will trip if they encounter smooth DC from something like an EV battery. Most wall chargers or EVSE equipment has this built in, however there are specific breakers available for EV circuits.

So When Is The Difference?

AS/NZS 3000:2018 Amendment 2, published on 30 April 2021, introduced Clause 2.6.2.2.2, to better protect against pulsating DC residuals from modern electronics, solar inverters, and EVs.

- There was a 24-month grace period for installing either Type AC or Type A RCDs.

- From 30 April 2023, Type AC RCDs were prohibited in new installations, alterations, additions, and certain replacements.

- Even a 3 year old house may require a switchboard rebuild.

You may need your glasses on to read the tiny pictogram, so if the battery sales team ask for pictures, make sure these are legible.

Poles Apart

1990 might feel like yesterday, but after 30 years switchboards will need work. I like to point out it’s a good opportunity, especially if you’re putting a whole package of upgrades together and using a green loan to pay for them.

If your electrician is swearing about poles, don’t worry, they’re not ranting about migration from the EU. Switchboards are sized to suit miniature circuit breakers (MCB) and each 17mm section is considered a pole. If your ‘board is pretty packed, then removing old 2 or 4 pole RDCs can create space needed for new solar circuits.

Happily there are now RCBOs to offer individualised circuit protection. Not only are they more compact, a single fault doesn’t take out a cluster of three circuits, or your whole house.

However even cheap junk RCBOs cost $30each, so a modest single phase upgrade board might use $500 in parts alone.

Here we’ve superimposed a hybrid solar inverter to show partial home backup. Arrowed in blue, TWO downstream circuits, have Type A RCBOs. The single RCD would be grandfathered as compliant last century.

Site Inspections Solve Problems

Adding an unexpected additional expense on installation day might sound like an opportunistic tradie is taking you for a ride, but the real shonks are those foisting responsibility onto electricians without giving the customer the whole picture up front.

It’s important to understand and document what you’re buying and what’s in the fine print in terms of exclusions.

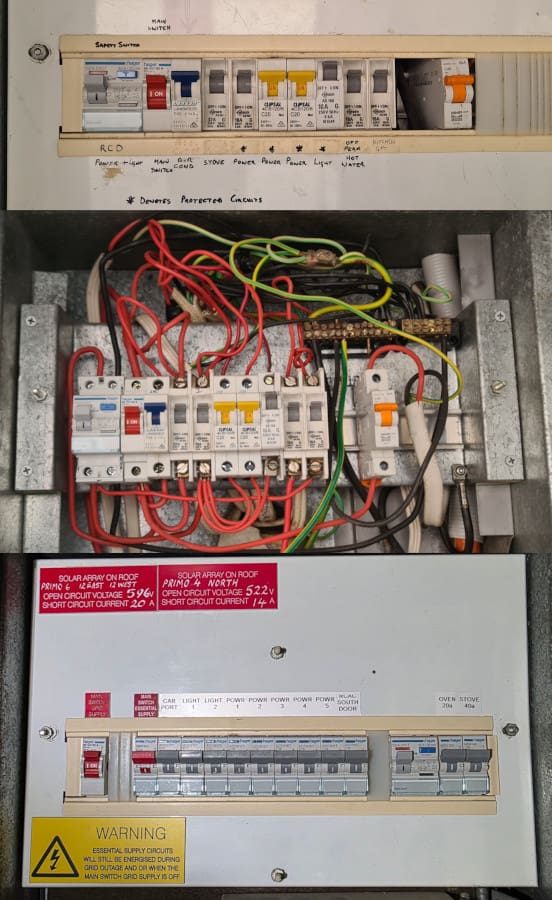

Originally 6 ceramic fuse circuits, 10 poles have been added in 9 enclosures. This is guaranteed to be a mess.

If you’re keen on having power during an outage, write down what you want to have working and get the salespeople to sign off on it.

Whether it’s partial blackout protection, ie lights, fridge and internet or it’s the whole house, including the rainwater pump, stove and the air conditioning, everyone must be on the same page.

Starting at the top, with a 1970s/80s switchboard that had a single RCD added for rental rules. This board now has whole home backup with RCBOs throughout and the two pole RCD reused for the oven/induction stove.

Batteries Mean Updates Are In Order

When you get a quote for a heat pump, EV charger, air conditioner, solar power system or battery, make sure you’re getting the whole story. Adding one piece of the puzzle with no real plan will always be more expensive.

Ad hoc installation of different brands of equipment means rework and compromise that can easily leave you with a lot of expensive but dysfunctional gear.

So make sure you confirm if a switchboard upgrade is required before locking in an install, so you can factor that into the cost.

For more on switchboard upgrades, read our explainer on why they are vital for all-electric homes.

Footnotes

- Body protected zones like hospitals and dental surgeries have even tighter requirements, they use 10mA safety switches ↩

RSS - Posts

RSS - Posts

Super informative as always, thanks Anthony.

I’ve also heard that if a switchboard is made of asbestos (mine is), there’s an obligation to upgrade it if major electrical work is being done to the board? Any truth in that? I’ve had I think 3 or 4 different electricians work on my board in the past 10 years, none replaced the asbestos board itself though one at least added a “caution contains asbestos” label. The board is so old the original installer’s phone number still painted on it is only 4 digits.

Its a mix of just avoiding costly and time consuming work and a bit of the legacy attitude to things like asbestos.

Ive had work done that by all rights should of triggered an upgrade as well.

Replacing things with parts that didn’t meet the exceptions “generally like for like replacement i believe it is thats allowed to keep grandfathered status”

P.s do not mess around with asbestos it’s what killed my father.

And there are probably who knows how many who die due to it that never get counted in the statistics.

I.e they were adamant they wouldn’t officially list the fibers in his lungs as asbestos and instead called them “unidentified fibers”

I wish you had posted this before I got my battery installed in October last year. The installer I went with (via your website for recommendations) never once mentioned board upgrades during the quote despite inspecting the board and taking pics. On the day of install, when they went to test the back up feature of the battery, the house nearly caught fire! My fridge, coffee machine and multiple lights went pop whilst a power board literally melted (as did several plugs in it) and singed our carpet. The installer blamed the old RCD. After I queried why they hadn’t checked this ahead of time they simply stated they were not required to. After several emails, I managed to negotiate a discount for the broken appliances with a commitment from them to come and upgrade the board at a further discount but once I paid the bill they have since ghosted me and won’t respond to my requests that I can safely switch the battery to back up mode without the house burning down which I haven’t done.

I’m going to guess you have 3 phase, because I can really only think of one major install fault that would cause what’s described.

I highly doubt it was the RCD.

As for the article I’ve questioned several “installers” posting that their solution does not require Type A replacements. I don’t know how they get away with it when inspections occur.

Damian Kelly

>Extremely bad service would be my answer.

Darren, why would a site inspection occur, and who would perform it?

A certain number of electrical installs get inspected after the contractor submits forms for the work.

It varies from state to state how many and when, some may never get chosen.

I know they were doing a blitz in Perth immediately after the rebate trying to nip any non-compliant practices in the bud but as normal far less were done in country.

Guy, if you are having problems with an SQ installer we want to know about it. Email nedATsolarquotes.com.au and we’ll help you get this resolved.

Even if the solar installer hadn’t quoted for new type A switches I would have thought Gould be legally required to put them in before issuing a certificate of compliance. If they have issued the certificate and not upgraded the switches then in NSW you could report them to fair trading as the work is not fully compliant! Is that correct

Hi Steve,

If an electrician has certified the job as compliant then it must meet the AS3000 rules.

If it doesn’t the technical regulator should be pretty interested in knowing who’s signing off.

Report the bastards.

Currently waiting for sign-off on a new implementation of panels, inverter and batteries. When negotiating the sale, I insisted I wanted whole of home back up with 2 big batteries. The company – sourced through Solar Quotes said that was no problem. Not what they normally advise but could be done.

On day of installation, the electrician said whole home was incompatible with my set up and I could either have 21 Amps covered or go and get different equipment (batteries & inverter) to cover 64 Amps. He said they wouldn’t do it because it would never pass inspection.

So, I’m left with much less than I wanted and am very displeased with my chosen supplier.

At the end of the day, I’m left wondering whether I got good or bad service from the electricians as no one had ever said I couldn’t do whole house before that.

Thanks Anthony. What are we looking for in a three phase switch for backup purposes?

Any chances you can update the article with this answer?

Why are the pictograms allowed to be concealed when the RCBO is turned on? That, in itself, allowing such critical information on electrical “safety” devices to be concealed, should be a criminal offence, with mandatory safety recall of such dangerous products.

And, why has a significant battery manufacturer been allowed to supply products that are non-compliant with Australian standards?

The article above justifies what I have contended some time ago, that every PV installation and every modification to a P)V installation, and, all electrical work performed, should be required by law to undergo and pass a statutory regulatory authority inspection upon completion, before becoming operational, with significant penalties for non-compliance.

It is unfortunate that that electrical work is unregulated in Australia, although, I believe that the state of Victoria has some form of regulation such as I have described as needed.

Public safety and government, tend to be mutually exclusive.

Hi Bret,

Electrical work in Australia is one of the most regulated trades and by international standards quite stringent.

A circuit exists that may have a load of up to 63A. That is the rating of the mains circuit breaker and the grid fuse on a single phase grid connection. The only protections for the total circuit, are the 63A mains circuit breaker and the 63A grid fuse. The switch – a switch, not a circuit breaker – directing power to that circuit was installed with a 25A rating. That switch was replaced after about a year, after the system started failing. That switch was replaced with a 40A switch – not a circuit breaker, a switch. The cabling to and from the switch, which cabling may have a load of up to 63A, is probably rated for a 16A circuit. No documentation exists to show otherwise for the cabling. This is all on a circuit that may have a 63A load.

The PV system with the BESS does not have any shutdown procedure instructions. Unexplained switches exist around the inverter, with their purpose unknown.

None of this has undergone any statutory regulatory inspection.

It is not required.

Hi Bret,

Have you got a compliance certificate for the work?

Have you spoken to the local technical regulator?

“Have you got a compliance certificate for the work? ”

No. The work is not documented – some of the work is mentioned in email messages, but no otherwise no formal documentation such as compliance certificates. I have copies of some “Notices of Completion”, but they are for other components of the system, and, none of the paperwork mentions the work involving the switch. I also have no paperwork for the replacement of the inverter that occurred under warranty.

I believe that I had contacted the inspectorate but I believe that the response was that it was “not their problem”. I think it was that they are not interested in anything that is downstream from the switchboard. At present, I cannot find the email communications involved in that.

I appear to be mistaken, regarding not having any compliance certificates.

I have two document that have the title “Electrical Safety Certificate”, and, in reading down the text on each page, the text contains

“This Electrical Safety Certificate is the certificate of compliance referred to in Regulation 52B of the Electricity (Licensing) Regulations 1991. This regulation requires that the electrical contractor/authorised electrician installing work must, with (sic) 28 days of completing the work, provide a certificate of compliance in respect to (sic) the work to the person for whom the work was carried out.”

1. I assume that the Regulation is a WA state regulation.

2. If you provide to me a direct email address, I can send copies of the documents. My email address is included in the form submission details.

3. The documents do not include reference to the cabling rating, the switches involved, the replacement of the 25A switch with the 40A switch, or the inverter replacement.

If you have a concern about the safety and technical compliance of your solar PV system, you can contact Building and Energy on 1300 489 099 or [email protected].

With my last previous post above about this, I did not include (restricted by length restrictions on posts) that the cabling of unknown and probably inadequate capacity passes through about 10m of roofspace, under a terracotta tile roof, in which roofspace, the temperatures can get quite warm – the next nine days have one cool day with a forecast maximum temperature of only 34 degrees, otherwise the next nine days have daily maximum forecast temperatures of 35-37 degrees, and, we often have a few consecutive days of 40-45 degree ambient temperatures, more than once during the warm season.

A month or so ago, a house a couple of houses along on this street, was destroyed by fire, which can happen, when electrical safety regulation is missing.

This is Western Australia.

Another thing I’d like to add – installing an active link bar is a Really Good Idea. Makes extra circuits very easy to add and avoids the awful tangle of conductors twisted and jammed up into the MCB.

Safer, neater and great for the next guy who needs to work on the board, which if you do a good job, might be you!

Hi Beau,

Bussbar with matching circuit breakers is better.

If you reckon an active link is a nifty idea then go post it on some socials frequented by electricians… While DNSPs use them under seals, I think you’ll find the industry is pretty hostile to active links downstream of the main switch.

Hi Anthony.

Yeah you’re probably right to be honest. I don’t see any prescription against active links in The Good Book, but I guess most electricians don’t encounter them often south of the main switch so are leery of them.

Hi Beau,

It’s a similar thing with old Weber circuit breakers pictured in the last image. They have exposed screws and some use exposed bussbar too.

I wonder if Sigenergy gateways are actually compliant because I have seen them with uninsulated bussbar connecting the circuit breakers too.

Geez don’t say that – the Sigenergy faithful might not survive another recall!

A very interesting article! I was wondering does the Sigenergy gateway box avoids the requirement to change the safety switches on the main house board by installing a Type A RCD switch on the Gateway and isolating the main house board from the battery? This would leave the house circuits all AC.

Would this be an option for other battery system installations?

Hi Mike,

The key phrase is “every final subcircuit”

So *final* means you can’t just install one device to cover an entire downstream switchboard.

There are no RCD’s in the Sigenergy gateway.

There is provision for an extra 5 din slots in some models – which may be used for extra backup/non backup circuits if needed. Or if you wire something (eg HWS) to the 63Amp smart port which then may require lower circuit/RCD protection.

You would not want any there either. Protecting mains supplies with RCD’s is just asking for false trip problems from combined low amount of earth leakage across multiple circuits.

If someone has said “gateway avoids the requirement to change the safety switches” I would consider that false.

I had a home battery ( with full home blackout backup ) installed in December. My electricity board needed to be upgraded – $1300 worth. A one off investment.

A bit related to this, any switchboard upgrade should include the replacement of the master/main isolator breaker. We didn’t because in SA, SAPN will allow an electrician to remove “their” master fuse to isolate the master breaker to enable it to be replaced, but they will not allow the same electrician (or any electrician apart from SAPN ones) to replace it. We would have had to book in an inspection by SAPN staff/contractor, and who knows how long that would have left us without power. Stupid rule.

A few months after the new solar, battery and switchboard upgrade, our 30-year-old master breaker tripped (no other circuit breaker did) and as we were away, our fridge contents melted. It has been replaced now. Apparently it had degraded so it was tripping at a much lower level than its rating.

Might be worthwhile as a separate Solar Quotes story on master fuses and breakers and the rules around who can touch them in each state.

Looking for a reliable Electrician in Ocala, FL? Vetcon Electricians deliver professional, on-time service every time.