A battery enclosure doesn’t sound like something that could change a market, but that’s what Dominic Spooner, founder and CEO of Brisbane-based company Vaulta hopes to do.

Vaulta offers the world a battery enclosure – with a difference: it can be disassembled right down to the individual battery cells without special tools or expertise.

And that means a lithium battery, for example, can be made repairable and much more easily recyclable.

Speaking to SolarQuotes, Spooner explained, he began understanding batteries and how they are put together because he was tasked with making batteries repairable in a previous job as a battery designer.

There are good reasons for an easily repairable battery: a failure might be down to a single cell, a cable failure, a connector failure, a dry solder joint in the battery management system circuit board, or more.

In a typical lithium battery, that means replacing the whole unit.

Once components go into a traditional battery pack, they’re never coming out:

“you’re relying on the whole battery lasting the duration.

We believe you need to be able to access the battery cells if there’s a failure. With our cases, there are no screws, no glues, and no welds,”

Spooner told SolarQuotes.

“That makes it possible to re-access the batteries once they go into the package”.

“If something that might cost $5 to replace cannot be replaced, and that will render the battery as end-of-life.”

Handling the failed battery is its own saga:

“you might have 200kg worth of stuff – who pays for the dangerous goods freight? What of all the non-dangerous goods in the package, all the plastics, all the metals? You end up paying dangerous goods freight rates on that stuff.”

If the battery can be easily disassembled,

“only stuff that needs to go to the end-of-life facility has to go, without carrying everything along for the ride”.

That, Spooner said, takes a battery much closer to being part of a circular economy.

He said the approach is attracting interest from battery vendors, although to date, negotiations are in confidence.

Vaulta’s Batteries

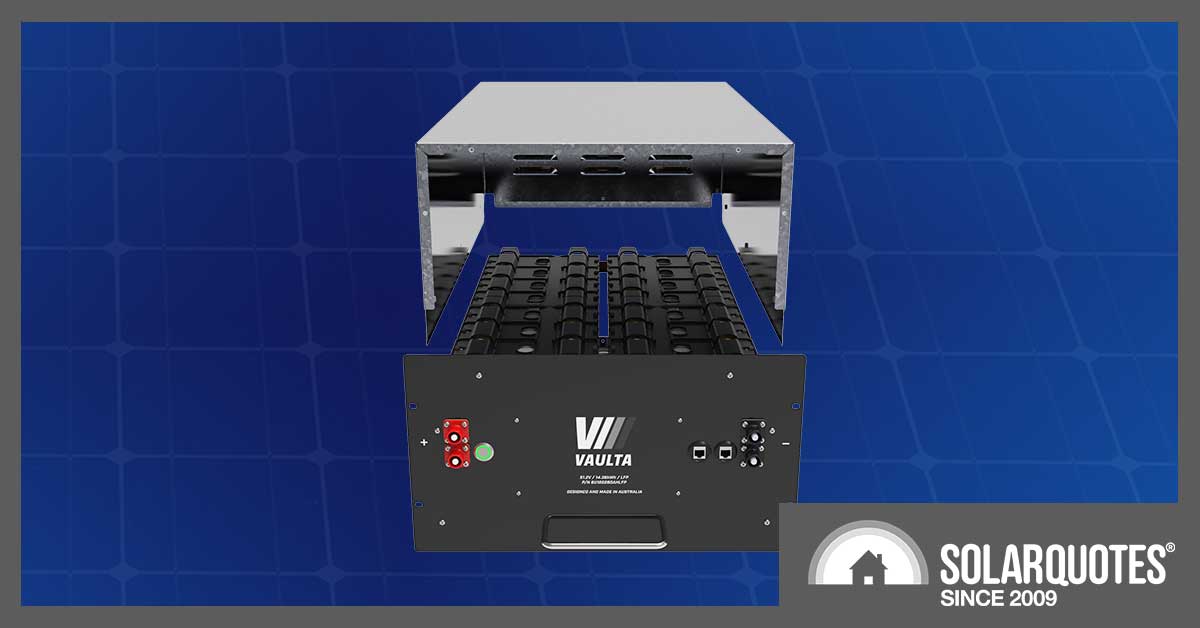

The company is also manufacturing complete batteries under its name, like this one, a 48V, 14.36kWh unit that offers a decent warranty – 3000 cycles equates to 43MWh delivered.

Warranty considerations are another reason to make a battery repairable, Spooner said.

“That’s built into our pricing model – we know we can replace a cell, a cable, the battery management system, a connector – not the entire item.

We can send finished goods with packages of critical spares. And furthermore, the current design is built in a simplistic manner without special tools”.

That, he said, means that local licensed electricians would be able to learn to repair the batteries.

That could be critical in remote locations:

“you can have it back up and running quicker without ultra-trained specially skilled service technicians. We can bring regions that aren’t part of the renewable transition, we can bring them along for the ride and get people trained.”

Australian Components

In keeping with the desire to have everything in the battery repairable, Spooner said, every component of the Vaulta battery that can be manufactured in Australia is built here.

The BMS, for example, is built in Brisbane, meaning Vaulta could work with the vendor to get the capabilities Spooner wanted.

“The BMS is 100% configurable to suit different inverter protocols,

We’ve been able to integrate inverters, with minimal contact with the inverter company, because we can adjust the protocols to suit the inverter.”

While Spooner wasn’t willing to disclose the shipped price of Vaulta’s batteries – it’s early days in terms of shipments – he said the company’s target is $600-$700 per kWh.

The speed of assembly of the Vaulta batteries is demonstrated in this short video:

RSS - Posts

RSS - Posts

A great video and a heart-warming reflection on why expensive modern products don’t need to be discarded when a small component fails. I would like to hear more about how Vaulta has managed to overcome the potential for deterioration in the connections to the batteries that may occur with atmospheric induced corrosion and thermal expansion and contraction. The welded connectors seem far more secure and reliable. Whilst the connectors would be attached in seconds when a battery is assembled in a robotic factory, the video shows clearly why onsite repairs to customer’s batteries would take a long time. It would be great if Vaulta has found the solution.

When my AGMs die, about 6 years time I’ll be in the market for the 48volt one. I’ve been 80% off grid for 15 years now and love the independence it brings.

A very interesting post. The fine granularity of repairability is unsurpassed.

I am,however, examining the option of a 13.4 kWh 48v battery comprising 16 serial connected 304 AH LiFePO4 cells, with just 15 chunky Cu busbars, simply bolted together like meccano. A torque wrench is needed, though.

Those cells are supposed to be good for 6000 cycles of 80% DoD. Given that even limiting cell voltage to 3.45v can reach 99.6% SoC, left long enough to charge, and 3.55v will do it in half the time, That’s easily set on a good MPPT. A BMS to prevent any cell going over 3.65v is essential, and an active balancer, only enabled as needed, puts you in control. Bluetooth to a phone app, or RS485 connectivity to Victron VRM suits my fastidiousness.

The big cells are doubtless not for dilettantes, as the short-circuit current risks flash burns. But once the busbars are covered, and a BMS (heck even a 200A Daly) fitted, then it’s a serviceable battery at a good price. (200A ~ 10 kW, which should even start the 2 kW induction motor on the compressor, given a bit of BMS surge margin. And two Victron Multiplus II/5000 in parallel could do 18 kW for some seconds if the BMS allowed.

I’ll be avoiding the really cheap cells out of China, as some of that appears to be crap, but even locally sourced cells at twice the price are competitive.

Once the fixed battery is done, I plan to assemble one with flexible busbars and mechanical restraint, for an EV garden tractor. (Haven’t sourced the motors for that yet, but have some links saved. It’s easiest if they’re bought with controllers.)

The pictured small round cells seem fine for campers to put in a caravan, but a bit fiddly for an off-grid home with lathe, milling machine, welder, compressor, and a bunch of woodworking machines in addition to aircon, sundry domestic loads, and EV charging. But the death of that Queensland DIYer on DC around 100v, has to be sobering. Electrons do not announce their intentions. Best keep ’em confined.

Keep us up to date on this please. Sounds promising.

A configurable, repairable Australian product, wow!

It would be great to see this added to the Solar Quotes comparison table, linked back to this article and the table extended to include place of manufacture.

I have a solar system and looking at batteries and have quotes how does the Vaulta system stack up against the power wall price wise and life of batteries.

I like Australian made

Regards Les