China’s Solar Top Runner Program – What The Hell Is It?

China is the world leader when it comes to manufacturing and installing solar panels.

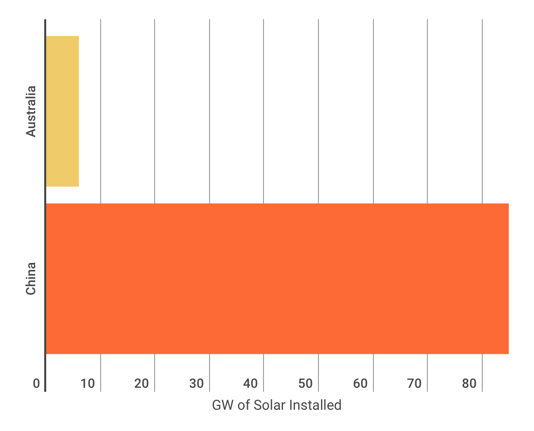

They currently have 85 gigawatts of them lying around on racks and producing clean energy by sunbathing1. This is 14 times Australia’s 6 gigawatt capacity.

China has 14x as much installed solar as Australia.

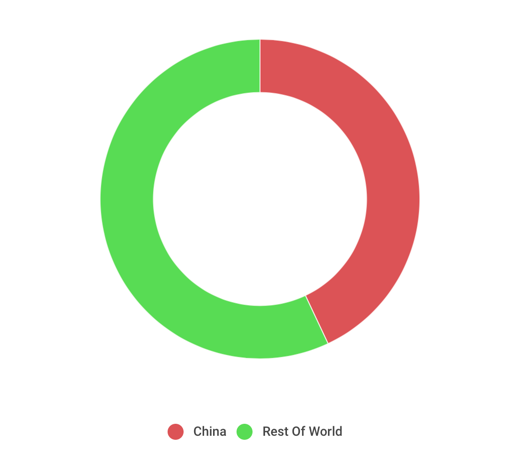

Australia still has 4 times as much PV per person, but China is catching up fast. Last year they installed 30 gigawatts or 5 Australias worth of solar panels. That was around 43% of all the PV installed in the world that year.

China installed 43% of the world’s solar capacity in 2016.

China also has a vast number of solar hot water systems that seem to be everywhere. I would not say they are ubiquitous — but only because I don’t actually know what that word means.

China’s massive and expanding solar capacity did not come about by chance. For some reason the Communist Party of China doesn’t rely entirely on market forces to allocate resources2. Normal Chinese solar farms receive a feed-in tariff that is above the average wholesale price of electricity. This government subsidy is designed to encourage the development of clean energy and reduce the number of Chinese three year olds who have the lungs of a chainsmoker. They also have a PV for the alleviation of poverty program, designed to benefit people in the poorer regions of their nation. And to promote the development of technologically advanced, high efficiency panels, China has the Top Runner program.

While it may be hard to believe, despite his massive popularity in China, Tom Cruise has nothing to do with their Top Runner program3.

It wasn’t easy, but I was able to use the internet to find out just what the Top Runner program is. In this amazing, interconnected world where Australians can download 2, 3 or sometimes even 4 cat pictures an hour, we have the ability to instantly learn about the latest developments in China. After, of course, they have been approved for release by the Ministry of Industry and Information Technology4, and after they have been squeezed through the corroded, verdigris encrusted, copper carbonate in the shape of wire, that we call a telecommunications system. A system laid down by grandad back in the days when bandwidth was something only narrow dance halls had to worry about. (It’s a pity China wastes so much effort controlling access to information when all they really had to do was put Malcolm Turnbull in charge of their internet.)

What I have learned is China’s Top Runner program is a scheme to improve the quality of their solar panel manufacture. It works by setting aside solar farm capacity that can only use panels that meet the Top Runner program’s efficiency standards.

By providing a market for higher efficiency panels, the program has encouraged Chinese manufacturers to invest in the means of production that improve the quality of their panels. This has been bad news for SunPower, LG, and other makers of high efficiency panels, who are facing increasing competition as Chinese products improve, but it is only good news for Australia and the world in general.

What Is A Top Runner Program?

A Top Runner program is a government scheme designed to improve energy efficiency. The way it normally works is: standards are set for products and manufacturers that don’t meet them by a set date suffer penalties that can include a ban on sales.

Australia’s lighting phase out, which kicked incandescent light bulbs5 out of the country, is an example of a top runner program, even though we didn’t call it that.

The most famous Top Runner program is Japan’s which has been operating since 1999 and now covers a wide range of products from appliances to vehicles. Their program has been a boon to the entire world by improving energy efficiency technology that eventually gets used everywhere.

Well, I say Japan’s program is famous, despite the fact that almost no one in the English speaking world seems to know what a Top Runner program is. I had to find out from a German article. Thank goodness I have enough German genes to understand it. (That’s how language works, right?)

The fact English speakers don’t even seem to know what Top Runner programs are suggests we’re not putting as much emphasis on energy efficiency as we should. I blame the United States for this. And Australia. And the UK. And Canada. And while it’s completely unfair, I’m also going to blame India — that’ll teach them to be the world’s second largest English speaking nation.

But China’s solar Top Runner program doesn’t quite work the same as Australia’s light bulb elimination program, or Japan’s Top Runner program. They are doing their own thing.

Lost In Translation?

“TOP RUNNER? ARE YOU MAKING FUN OF OUR LACK OF LOCOMOTORY APPENDAGES?”

Some of the documents I got information from were difficult to understand because they were translated from Chinese into English by a machine. Quite possibly a Dalek.

At least with German I can understand something well enough to know if I need to use Google Translate on it, but when it comes to Mandarin I’m afraid I don’t know if I am looking at something that’s to do with the solar Top Runner program or Sound of Music fan fiction. (So-Lar-Mi-Re-Doh.)

While I am confident what I have written below is correct, it is still possible something has been lost in translation, despite using one source whose English mine better than is.

How China’s Solar Top Runner Program Works

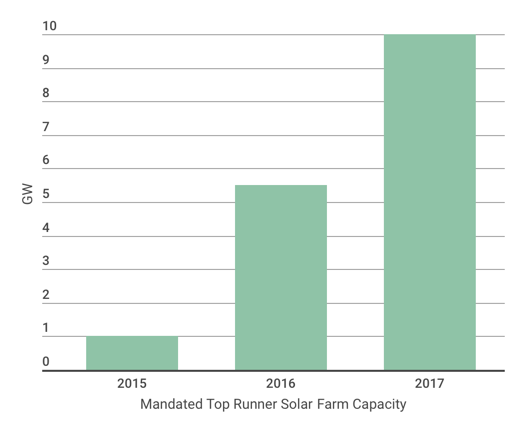

China’s solar Top Runner program started in 2015. It mandates that a specific amount of solar farm capacity built each year, must only use panels that meet the Top Runner efficiency standards. The mandated build program for these ‘Top Runner’ solar farms is increased each year:

- 2015 — 1 gigawatt = About one Victoria worth of PV

- 2016 — 5.5 gigawatts = About one Australia worth of PV

- 2017 — 8 to 10 gigawatts = About one and a half Australias worth of PV

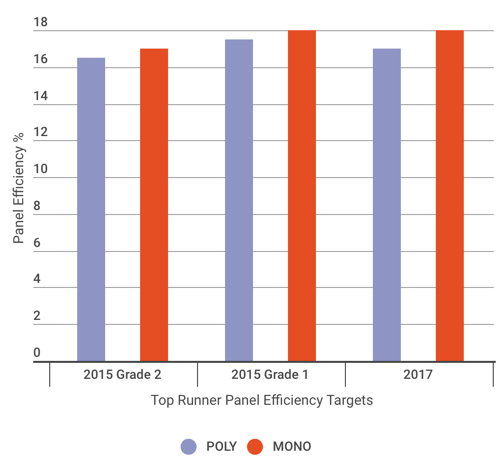

Polycrystalline and Monocrystalline Efficiency Standards

The Top Runner program has efficiency standards for both polycrystalline and monocrystaline panels.

Polycrystalline silicon, also known as polysilicon and multicrystalline silicon, is cheaper, but solar cells made with it have a lower efficiency than those made from monocrystalline silicon. And because having just one name would be too simple, another term for monocrystalline silicon is monosilicon.

In 2015 and 2016 the Top Runner program had two efficiency grades:

- 2015 Grade 1: Polycrystalline 17.5%, Monocrystalline 18%

- 2015 Grade 2: Polycrystalline 16.5%, Monocrystalline 17%

Some solar farms required panels meet the strict Grade 1 standards, while the more laid back ones accepted Grade 2 standards.

In addition to meeting efficiency standards, 60 cell solar panels, which are the most commonly used size, had to be at least 280 watts in capacity.

In 2017 there appears to only be a single efficiency standard:

- 2017: Polycrystalline 17%, Monocrystalline 18%

With the minimum capacity for 60 cell panels increased to 295 watts.

Top Runner targets force the average Chinese panel to be more efficient.

Quotas For High Efficiency Technology

To encourage further development of higher efficiency panels, small allotments of at least 50 megawatts of capacity are set aside for panels using specific technologies which include PERC6, IBC7, and HIT8.

Since 2015 when the Top Runner program started, PERC cells have gone from being a small share of the market to becoming standard in most new solar cell production lines. While the PERC quota wouldn’t have hurt, the main reason has been that PERC’s increased efficiency allows both polycrystalline and monocrystallline panels to meet the Top Runner efficiency standards outside of PERC’s specific quota.

Top Runner Uses Reverse Auctions

Normal solar farms in China receive a feed-in tariff for the electricity they supply to the grid. The amount of new solar capacity that can receive it is determined each year. Total compensation is decreasing to reflect the declining cost of solar and solar farms built this year will receive around 17% less per kilowatt-hour than those built in 2015.

Top Runner capacity is done differently and uses reverse auctions. This is where whoever offers to build a solar farm that meets the Top Runner efficiency standards at the lowest cost wins. Reverse auctions are an excellent way to ensure companies make enough money to stay in business, as they are unlikely to bid a price that will drive them broke, while still making use of competition to keep prices low.

Reverse auctions have proven to be very effective at providing renewable generating capacity at low cost. In the United Arab Emirates (UAE) the method has resulted in solar being bid in for a price of around 3.3 Australian cents per kilowatt-hour and in India 4.9 Australian cents per kilowatt-hour.

In China, the lowest cost solar farm I am aware of, was bid in for 59 Australian cents a watt9 and that was for the Top Runner program. This is an astoundingly low price and less than half that of Australia’s lowest cost solar farm projects. While this suggests the polycrystalline panels of at least 16.5% efficiency that were used are now the cheapest way to build large scale solar farms, I can’t be certain of this because the Top Runner solar farms may have had grid connection or other advantages over projects that weren’t part of the program. But it’s definitely a good sign and it won’t be that long before panels that are less than 16.5% efficient almost disappear. They have definitely become less common in Australia.

Because China isn’t doing anything magical when it comes to solar farm construction, there no reason prices in Australia can’t at least approach theirs10.

The Benefits Of The Top Runner Program

It’s not possible to know what would have happened to the Chinese solar industry if the total amount PV they installed was the same, but there was no Top Runner program. Personally, I am sure the cost of solar panels would still have fallen to around what they are now and efficiencies would have improved.

But I am also certain they would not have made the same gains in panel efficiency without the program. One definite effect has been to increase the amount of monosilicon solar cells produced in China, as well as the number of panels that use PERC technology.

Improvements in panel efficiency are all good for Australian rooftop solar because the higher the efficiency, the less space is required and the greater the savings on balance of system costs such as racking, wiring, and labour.

The improving efficiency of Chinese panels are a challenge for makers of high-end panels. SunPower, the maker of the world’s highest efficiency panels, appears to have decided that if you can’t beat ’em, join ’em, and will begin manufacturing panels in China. What the South Korean manufacturer, LG Solar, will do remains to be seen, but perhaps they intend to always stay a couple of steps ahead of the competition. I hope they’ve got their best running shoes on, because they’ll have to be a top runner to win this race.

Footnotes

- China also has over 170 gigwatts of wind power capacity, which produces more electricity than their nuclear energy program. ↩

- Australia and China currently have a similar level of taxation as a percentage of GDP, but China’s is usually higher. ↩

- If you ever wonder why Tom Cruise runs so much in his movies, it’s because all a director has to do is say Xenu is coming to get him. ↩

- The Minister is charge is Miao Wei. As far as I am aware, he has never met the Dutch Minister for Cheese, Kat Peerce. ↩

- Contrary to popular belief, or unpopular belief, as not many people actually care about these things, incandescent light bulbs aren’t banned in this country. They just can’t be sold if their efficiency is under 15 lumens per watts. If you get them above that limit you can start selling them again. If you want to revive him and get him working on it, Thomas Edison is buried under what looks like a slab of concrete in New Jersey. (Appropriate, since Edison did love his concrete.) ↩

- PERC involves using a “laser” to cut tiny slits that allow electrons to squirt into a solar cell’s bottom more effectively. ↩

- IBC eliminates the need to put wires on the front of solar cells and prevents the shading they cause. ↩

- HIT cells are monosilicon cells wearing a thin skin of amorphous silicon. I can only speculate they are called HIT cells because they take out a hit on amorphous silicon cells and then wear their victim’s skins. This would also explain why you so rarely see amorphous cells these days. ↩

- Cost per watt is how much a solar farm costs to build. At 59 cents a watt a 100 megawatt solar farm with 100 million watts would cost $59 million. This figure alone is not enough to work out how much the electricity it produces will cost, as it will depend on location and other factors, but obviously the lower the better. ↩

- Because sunlight is free, the cost of capital is the most important factor in determining the cost of solar farms. Technically interest rates are lower in Australia than China, but I don’t know how the real cost of capital for solar projects compares in reality between the two countries. Labour is cheaper in China, but is only a small part of the total cost of building a solar farm. ↩

RSS - Posts

RSS - Posts

“In the United Arab Emirates (UAE) the (reverse auction) method has resulted in solar being bid in for a price of around 3.3 Australian cents per kilowatt-hour and in India 4.9 Australian cents per kilowatt-hour.

In China, the lowest cost solar farm I am aware of, was bid in for 59 Australian cents a watt ”

Is that a misprint ? I’m struggling to equate cents per kilowatt hour against cents per watt.

Sorry, yes, that is a little confusing. Cents per kilowatt-hour is how much the solar farm gets paid for the electricity it produces. I had that figure for the UAE and Indian examples, but not the cost per watt, which is how much a project developer agrees to build a solar farm for, based on how large it is. So at 59 cents per watt, a solar farm with 100 million watts of solar panels would cost $59 million dollars.

I will add a footnote to hopefully clear things up.

In southern rural NSW I am being quoted $1.50/ watt for tier1 battery ready system on tilts, with data cable limiter from inverter to export meter- currently limit is 3Kw max export to grid. An article on this aspect of the economics of increasing a small rural system would be enlightening to some.

Ronald, your information pushes me into a rethink. If “60 cell solar panels, which are the most commonly used size”, then maybe I shouldn’t dimension my 30 degree sloped north-facing roof for 2m x 1m 72 cell panels? (Getting closer now to finalising plans for council – the soil test is done, so after foundation design, the trusses need to be designed.)

A 3.5m roof slope length would leave e.g. 1m gap to the ridge, and 0.5m gap to the spouting. That’s hopefully enough to minimise trouble with wind trying to rip the array off the roof, as global warming eventually brings stronger winds even to 38 degrees south latitude. I suppose 1.65 x 1m panels also fill 2m upslope if paired on the side, so maybe as-is-drawn will do, just with a different panel count. I hear that 1m should be left at the ends.

Incidentally, is steel decking any better than corrugated with regard to fixing an array? I like that decking clips in place without any penetrations, so is totally waterproof. If the array could affix to the ribs, then that would be doubly neat. I imagine that brackets could tightly clamp onto the ribs – is that fantasy?

You will certainly have more choice if you go for 60 cell panels. And a much wider choice of installers. But if you are planning to lay 2m x 1m 72 cell panels like this: |||||||||| Then you can also lay 1m x 1.65m panels like this ====== in the same space.

Oooops! You just got onto that in your second paragraph. I gotta learn to hold my horses — they need to be hugged every now and then.

On a corrugated roof, existing penetrations can be used to used to fix racks, so no new penetrations necessarily need to be made. But with a traditional corrugated roof, penetrations have to be used. I’m not aware of any other way to do it.

China’s 30 GW is impressive. It will be interesting to learn how much they can actually deliver considering quality of panels and the heavily overcast conditions inspired by pollution.