Image: CCT Energy Storage

Adelaide company CCT Energy Storage yesterday took the wraps off its thermal battery, a device it says has unique capabilities.

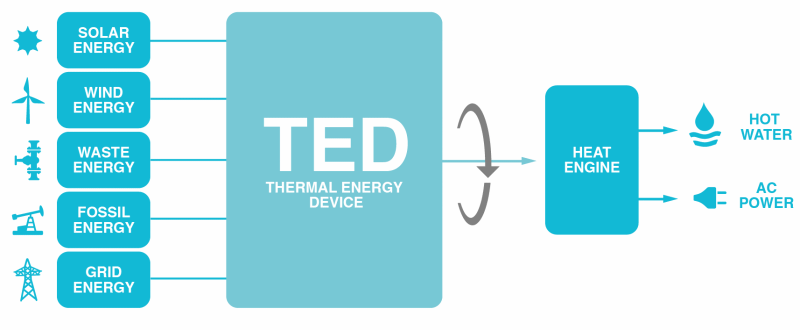

CCT’s Thermal Energy Device (TED) can accept any form of electrical input – including from wind and solar power – and convert and store this energy as heat using molten silicon as the storage medium. This heat can then be utilised or turned back into electricity when required.

” TED’s ability to manage input variations, produce base load output, take shallow cycle input and charge and discharge simultaneously … meaning the applications are extensive,” states the company.

As to the specifications of the battery in the photo above, there didn’t appear to be any information publicly available at the time of writing. It’s been claimed TED can store energy at 12 times the density of lead-acid batteries and approximately five times the density of lithium-ion technologies.

According to an article on BusinessDailyMedia, TED can be scaled up from 5kW applications to large scale applications of hundreds of megawatts.

“Readily scalable, TED will be used to power remote communities, commercial businesses telecommunications networks and transport systems – with 10 TED units to be supplied to commercial customers this year and production expected to increase by more than 200 units by 2020,” says CCT.

While CCT Energy Storage will be producing TED units commercially itself locally, last month it signed a manufacturing agreement with MIBA Group in Europe, which will exclusively manufacture and distribute TED to Denmark, Sweden and the Netherlands.

The launch event yesterday was attended by South Australian Energy Minister Dan van Holst Pellekaan1, who seemed pretty excited about the tech.

CCT Energy Storage was established in 2011 and its first working scale prototype was produced in 2012. The company’s operations are based at Lonsdale, where prototype design, construction and assembly and testing are carried out.

Not The Only Thermal Battery Show In Town

CCT isn’t the only company in Adelaide developing thermal batteries based on molten silicon that can work with renewables such as wind and solar power. 1414 Degrees2 is currently finishing up on installing its biogas version – GAS-TESS – at SA Water’s Glenelg Wastewater Treatment plant. SA Water is trialing the system to help it meet a target of zero net cost energy from 2020.

1414 Degrees is also working on its 200MWh+ TESS-GRID, which is designed to provide energy security in electricity markets with substantial renewables-based generation.

It appears there’s been some legal wrangling between CCT Energy Storage and 1414 Degrees in the past over intellectual property related issues.

Footnotes

- Minister van Holst Pellekaan really, really likes batteries ↩

- The name 1414 degrees is taken from the temperature (Celsius) at which silicon melts ↩

RSS - Posts

RSS - Posts

I notice their website is careful not to mention round-trip efficiency.

Absolute maximum possible theoretical recovery is ~80%, and likely to be much less in practice. If you can use the waste heat for something useful it wouldn’t be so bad, especially if the generated electricity would be wasted otherwise.

Consiering power stations run at 20% efficiency how does heat remained stored without loss?

The biggest reason that thermal power stations have relatively poor efficiency (typically ~30%) is because the steam they use to drive their turbines isn’t very hot (500 – 700 degrees celcius). The laws of thermodynamics mean that, for a power station which converts heat into electricity, the efficiency goes up when you increase the temperature of your heat source. Coal-fired and gas-fired stations use water which means running above 500 degrees becomes difficult because very high pressures are required to raise the boiling point of water so high.

The silicon thermal battery looks like it operates at 1400 Celcius which is very much hotter than power stations and could in theory be much more efficient.

I do wonder what they use to convert the heat back into electricity, if they use a working fluid like water they’ll get at best the same efficiency as a normal thermal power station.

And actually, the 1414 website has a lot more technical details and says “15-40% electrical efficiency”, it talks about Stirling engines using air as the working fluid, so I guess it’s nothing magical after all

And like you say, they must have extremely good insulation to stop the heat escaping and losing all the stored energy. 1414 claims “up to a week” and that the daily cycling means it’s not a big issue.

(Actually to be technically correct, most gas-fired stations use hot exhaust gas for their turbines instead of steam (or- as well as steam). This helps them be somewhat more efficient than coal-fired plants, but still less than 50%)

80%? try 10%. I’m pretty sure their energy recovery device is a “thermoelectric device” using Seebeck Effect, aka a reverse Peltier. The best commercially available units (Alphabet Energy) have an efficiency under 7%. The research aims to get to 10% via exotic-er materials. And that’s just in the recovery stage. Sure, the cooling system gets you low-grade heat you could maybe use too. But it’s gotta be pretty low grade (ie cool) to enable the thermal gradient necessary for the device to work.