Backsheet failures from the field. Images: Crap Solar FB Page

On the 19th of June DuPont, the world’s largest chemical company, released their Global PV Reliability 2019 Field Analysis report. It contains disturbing news on the reliability of plastic backsheets used for solar panels.

Fortunately, polyvinyl fluoride Tedlar plastic backsheets have an incredibly low failure rate. And those backsheets just happen to be made by DuPont. Talk about luck!

To prepare the report DuPont gathered information from 355 separate solar installations with a total of 6.5 million solar panels — or modules if you want to be technical.

I doubt they inspected all 6.5 million panels. That would be really tedious. If a worker spent one minute per panel 40 hours a week it would take 52 years to inspect them all. I think they just sampled a selection at each site.

Dupont Loves Their Backsheets

DuPont has some people who are fixated on producing backsheets for affixing to the backsides of solar panels. You could say their interest lies on the side where the sun doesn’t shine. While there are those at DuPont who have made their careers covering solar panel rears, this is not the only reason they published their report. I will quote their goal in their own words — shortened for brevity:

“Our mission is simple yet critical: to inspect, ass…”

Perhaps I should try that again, but this time with less brevity:

“Our mission is simple yet critical: to inspect, assess and understand the state of degradation of fielded PV modules.”

DuPont Own The Tedlar Name

The report definitely makes DuPont’s Tedlar solar panel backsheets appear to be wonderful. The good news is, as far as I can tell, they are. Australia’s only panel manufacturer — Tindo Solar — uses them due to their high quality and durability.

What the report doesn’t reveal is Tedlar is only a brand name DuPont owns. They invented the polyvinyl fluoride plastic it uses back in 1949 and first sold it in 1958. If they took out a patent in 1958, it would have expired in 1978. Other companies would have been free to manufacture and sell it for over 40 years. So DuPont is not the only potential source of Tedlar material. They’re just the only ones who can call it Tedlar.

But in the United States you can slap two technologies together that are each over 60 years old and attempt to get a new patent for it, as this patent application for solar panels that use polyvinyl fluoride plastic backsheets shows.1 As I can’t find mention of companies other than DuPont using the material for backsheets, it looks to me like they have maintained control over this backsheet material.

What Is A Backsheet?

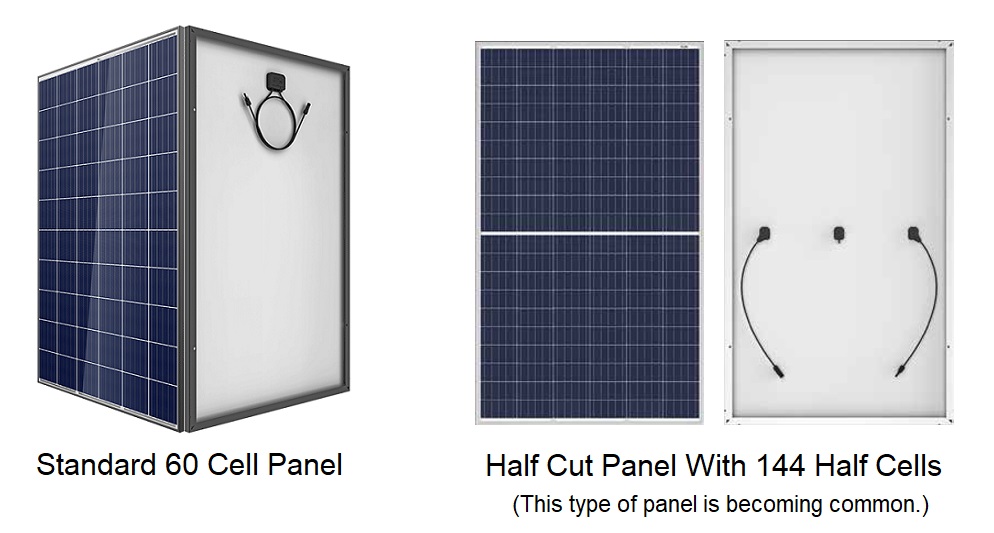

A solar panel backsheet is the white plastic at the back of a solar panel. I’ll show you a picture. They say one of them’s worth a thousand words, although I’m such a succinct writer it’s more like 240.

(Images: Trina)

If you are looking at some kind of bluish grid, that’s the front of the panel. If you are looking at a white area inside a rectangle with some cables sticking out of it, that’s the backsheet. They are vital for providing physical protection against wind blown dust and debris and, most importantly, they prevent water getting in and ruining the panel. The material has to be waterproof and long lasting, as most solar panels have performance warranties of 25 years.2 Solar panel backsheets are usually white because if the sheet visible between solar cells reflects sunlight the panel will be a little cooler and this aids efficiency.

Here’s another illustration that shows how the silicon sandwich that is a solar panel is put together. I hesitated to include it because it makes the encapsulant — polymer glue that holds solar panels together — look like solid sheets of glass when it is more like flexible sheets of plastic before it’s heated and becomes an adhesive that holds the panel together.

Now I’ve explained what a backsheet is I’ll go into what the Dupont report says.

Executive Summary

The report’s executive summary says bugger all of any substance. I can’t decide if this is because the people who wrote the report thought their executives are stupid or it’s because Dupont executives think other executives are stupid. Either way, you have to get past the executive fluff to find useful stuff.

One-Third Of Panels Defective

As the graphic below shows, the report found one-third of inspected panels were defective:

They provided this doughnut chart3, but no information on how it was put together. This means I have no idea how they accounted for the significant number of panels that would have had more than one type of defect. If these were double counted then more than 67% of the panels may have been alright.

The two most common defects were with:

- Solar cells and the connections between them, and…

- Backsheets.

These problems are neck-and-neck at 14% each on the doughnut graph. I’m going to focus on problems with solar panel backsheets, as that’s what the report does, but the other defects are still serious issues that can lead to panel degradation and failure.

Backsheets Defects Rising

The report gives the following summary on defects:

I don’t know why they say total module defects are 34% here and only 33% on the doughnut graph above, but what’s 1% between friends? A more serious concern is the number of backsheet defects appears to be increasing rapidly with panel age. In 2018 they examined panels with an average age of 3.3 years and 9.5% of them had defective backsheets; while this year the defect rate is 14%. Because they greatly increased the number of solar power installations examined this year and don’t tell us the average age, it’s not clear that one extra year of aging caused the increase in defects — but it does seem that way.

If backsheet defects are rising rapidly as panels age then many are likely to fail around 5 to 10 years after installation. This would be a blow for many solar panel owners and a boon for manufacturers that use durable backsheets.

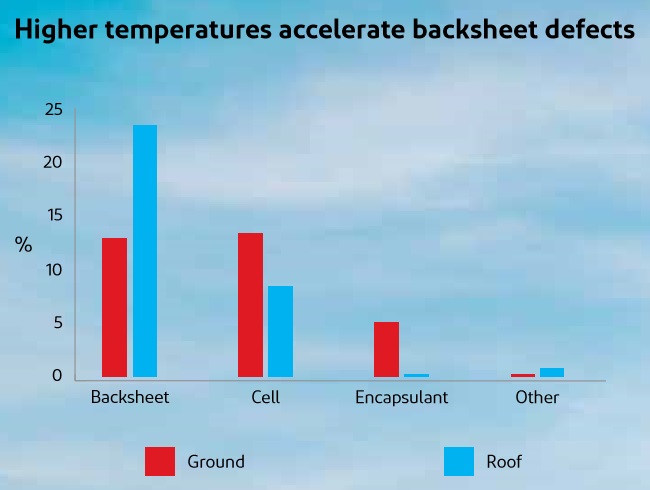

Rooftop Solar Has More Backsheet Defects

In solar farms air can circulate behind panels ground-mounted on racks and cool them. But panels on roofs often only have an air gap of around 10 cm, limiting this type of cooling. As a result solar panels on roofs average around 15 degrees hotter during the day and this increases backsheet defects as the graph below shows:

Types Of Solar Panel Backsheet Defects

The illustrations from the report below show the 5 different categories of backsheet defects and their frequency:

Air-side cracking — on the bottom left — occurs on the rear of solar panels and is the most common defect. It is followed by cell-side yellowing and cell-side cracking. Delamination — which is when the backsheet starts peeling off — is the most serious defect and, fortunately, the rarest.

Provided it’s not delaminating, a panel can continue to operate effectively for many years with a backsheet defect. But a defect is not a good sign and indicates a strong potential for future problems, even if a panel is currently working well.

How To Avoid Backsheet Defects

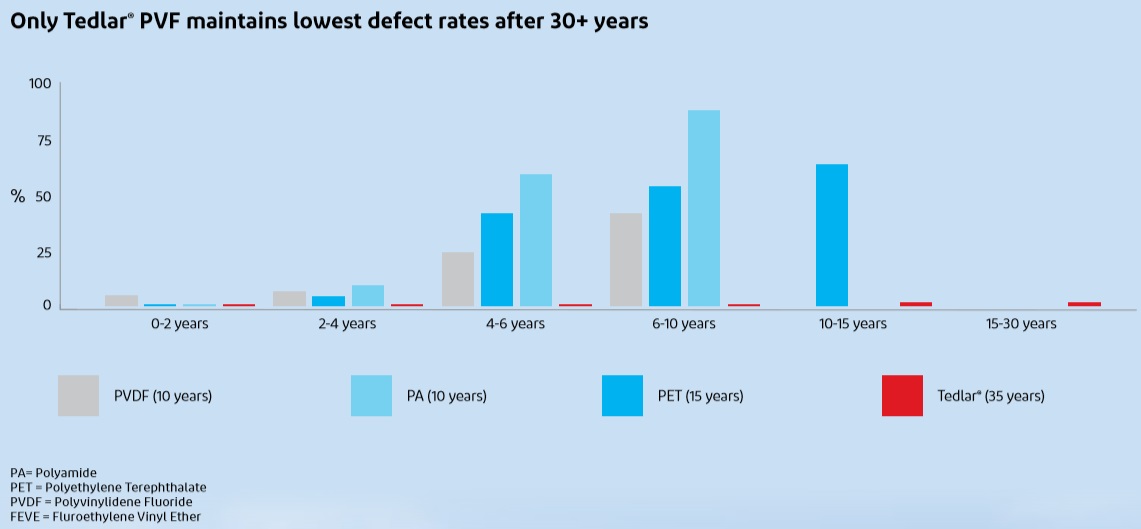

DuPont’s preferred method for you to avoid backsheet problems is – wait for it – to only use solar panels with their Tedlar backsheets. This will work because — according to their report — they have a freakishly low failure rate:

Backsheets made from lower cost plastics all have much higher defect rates according to DuPont. But whether or not there were high quality backsheets with defect rates similar to Tedlar that were inexplicably left off4 the graph for some strange reason, I don’t know.

If you are a home owner, there is not much you can do except buy good quality solar panels from a reputable manufacturer. If you want extra security you can check the manufacturer has a track record of happily replacing defective panels and is financially stable enough so they are likely to still be around in the future.

But if you are bulk buying solar panels from a factory in China or elsewhere, you have to make sure the Bill of Materials (BoM) for the panels you are getting — the exact list of the materials used — contains only high quality backsheets. Bear in mind that one panel model could have dozens of different BoMs and lots of different backsheets. Buyer beware!

Footnotes

- The patent system in the US has become so lousy technology might advance faster if they scrapped it entirely. ↩

- Beware of crap solar panels because their manufacturers have no intention of honoring their performance warranties. The lesson is — avoid crap solar. ↩

- Like a pie chart, except holier. ↩

- Actually, if they were left off, I think that would be quite explicable. ↩

RSS - Posts

RSS - Posts

Thanks for the article. It’s such a complex industry, and so hard as an outsider to get unbiased information … reports like yours are much appreciated.

Very good and informative article. Thanks for sharing. Definatly something to be aware of.

any idea who uses Dupont as their standard?

Disappointing the QCell panels appear to have an issue per the photo. These are not a cheap panel to buy.

Does anyone know much about Maxray panels? – these are used for low power portable solar applications as well as in caravans and off-road applications. maxrayaustralia.com is the local distributor, they don’t sell to the public, but through firms that specialize in off-road and camping, or portable applications. On checking the maxray website, they are rather vague about precisely who the manufacturer is, the only info is that the panels are sourced from Taiwan and are ‘high-quality’.

Not suggesting there’s anything wrong with them, could be they change suppliers from time to time for one legitimate reason or another, but just wanted to know a bit more about them. (the panels)

Here’s a link to the specs for a panel at one of the retailer sites

https://outbaxcamping.com.au/solar-panels/fixed/caravan/maxray-170w-12v-solar-panels-monocrystalline-caravan

thanks for any info from some-one who’s familiar with the panels or has used them

I’m afraid I don’t know of them and looking on their warranty page I couldn’t access their actual warranty.

Thanks Ronald.

There’s no ‘warranties’ on the Maxray website other than (quote): “Our goods come with guarantees that cannot be excluded under the Australian Consumer Law… etc etc …” which could perhaps be interpreted as meaning ‘the only warranties we’ll give are the ones we’re forced to.’

I’ll be giving them a miss I think. There’s lots of alternatives around, I should be able to find something I’ll feel more comfortable with.

Ronald. I just met your writing through this article and I think you’re hilarious. No joke. Thanks for putting on a good show.

Hi Ronald,

Are any there any Solar Panels which have a BAL (Bushfire Attack Level) rating?

Hi Grant

I’m not aware of any with a BAL level rating, but all solar panels have to pass a stringent fire test to be suitable for installation in Australia. The latest fire standards have been in place since July 16th 2013, so ones installed before this may not be as safe.

The greatest fire risk with solar panels is likely to be if twigs and leaf litter have been able to build up under the panel.

I have 19 x 240 watt, 8 year old Q Cells, all with the backs cracked like in the picture of the Q Cells above, I was wondering what I could use to reseal them to stop the moisture getting in, as they are still producing and I it would be a waste to throw them out. Obviously Q Cells are not suitable for the Darwin climate.